7

Inspection and maintenance

03.2018

67

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

7.7

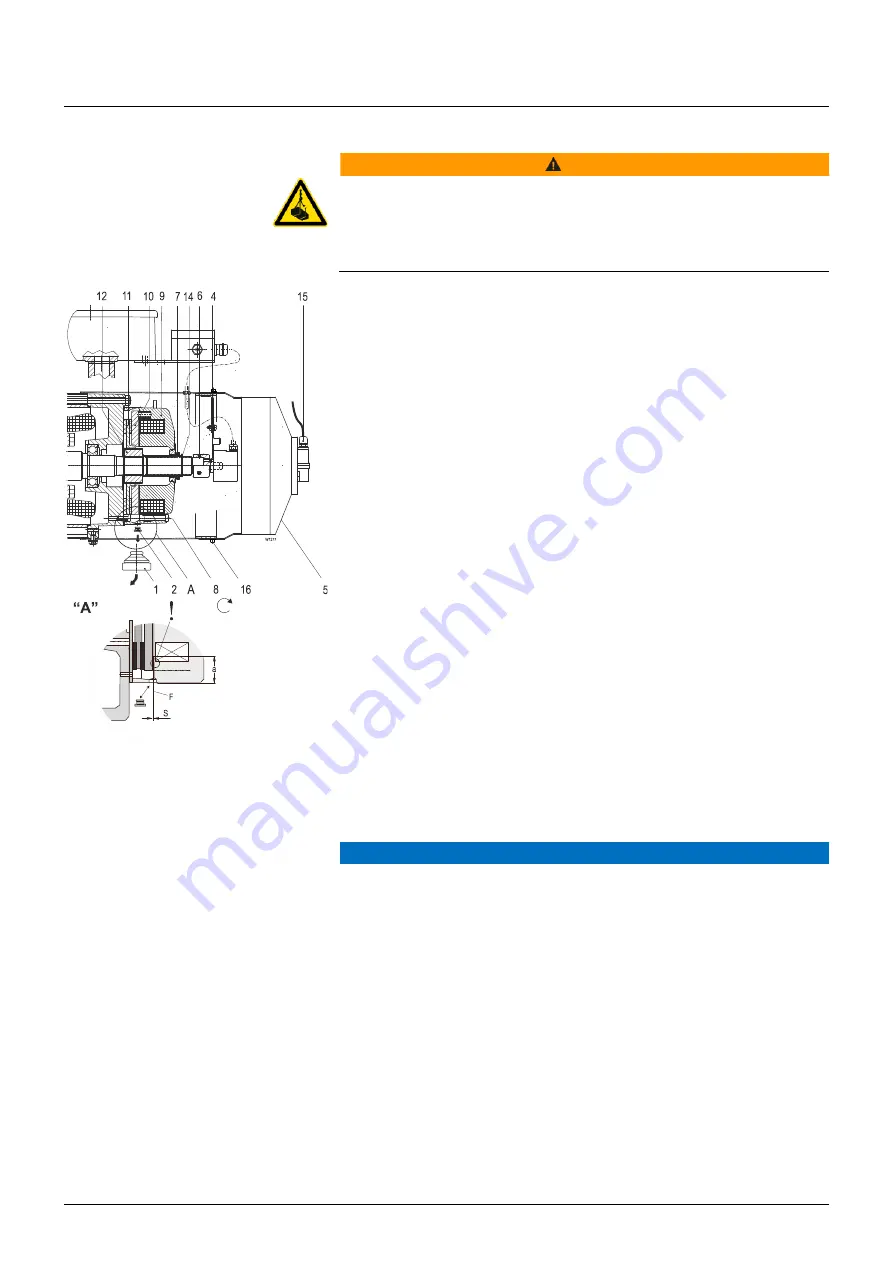

Hoist motor brake (NM) 4HS.

WARNING

Falling load hazard.

➢

Carry out work on the hoist brake only when the hoist is unloaded and the bottom

hook block has been set down.

➢

Before starting disconnect power and implement a Lockout/Tagout (LOTO) procedure

before servicing the equipment.

Fig. 75

7.7.1

Checking brake

1.

Remove plug (1)

2.

Remove plug (2) with pliers

3.

Measure air gap (S) with feeler gage (F).

4.

NOTE

: When measuring, ensure that the feeler gage is pushed in at least as far as

Tab. 33) and does not catch on shoulder (!). See Tab. 33 for max.

permissible air gap (S). The brake is not adjustable. If the max. permissible air gap

(S) has been reached, the brake disk (brake rotor) must be replaced.

7.7.2

Replacing brake disk (brake rotor)

1.

Remove plug (15)

2.

Remove fixing screws (16)

3.

Remove forced ventilation (5)

4.

Unscrew stud screw (4) (short hexagon socket s2)

5.

Pull off shaft encoder and leave it hanging on the connecting cable

6.

Unscrew stud screws (6) on adapter shaft

7.

Remove adapter shaft with lifting screws (M6)

8.

Remove V-ring (7) (IP66)

9.

Remove circlip (14)

10.

Disconnect brake

11.

Remove fixing screws (8)

12.

Remove magnet piece (9) together with armature disc (10)

13.

Remove brake rotor (11)

14.

Clean brake (wear a dust protection mask)

15.

Check friction surfaces for wear

16.

Push new brake disk (brake rotor) (11) onto hub (12) and check play. If there is

increased play in the gearing between brake disk (11) and hub (12) the hub (12) must

be pulled off the motor shaft and replaced.

NOTICE

Material damage hazard.

Always contact the manufacturer before removing the

hub (12).