7

Inspection and maintenance

72

03.2018

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

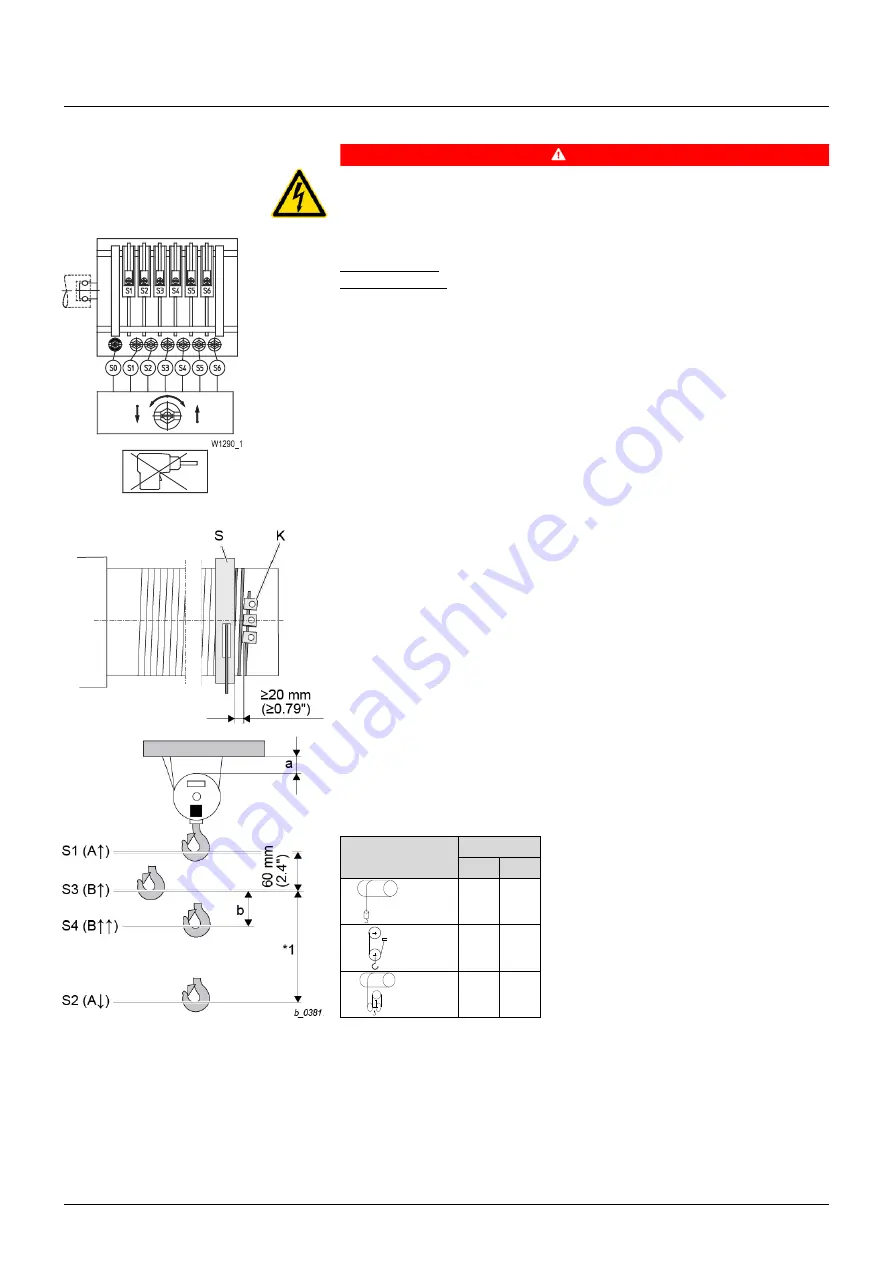

7.10.6

Setting hoist limit switch

DANGER

Electric shock hazard

The cover of the hoist limit switch must be removed to set the contacts. This exposes live

contact connections. Make sure an electrical qualified person performs the work.

Fig. 80

Fig. 81

*1 Effective hook path

Adjust hoist limit switch at the setscrews (S1) - (S6) depending on version:

Turning to the left: switching point is moved

“downwards”

.

Turning to the right: switching point is moved

“upwards”

.

Adjusting en bloc

All the cam discs can be moved together with the aid of the black setscrew (S0). The

settings of the individual contacts relative to one another remain unchanged (see

Set the limit switch using socket spanner (04 430 50 99 0) and without using undue

force. Do not use a power screwdriver.

Adjust the switching points in the following sequence:

1.

A↑ (S1)

2.

B↑ (S3)

3.

B↑↑ (S4)

4.

A↓ (S2)

5.

B↓ (S5) (option)

6.

B↓↓ (S6) (option)

When setting the hoist limit switch, observe hook dimension

“

C

”

as specified on page 76,

section

7.11 “Hook dimensions C for KE

-

S.. trolleys”.

Switching point A↑ (S1)

Emergency hoist limit switch top hook position

1.

Set without load in creep lifting.

2.

Lift bottom hook block to

a+0.39 in.

(see illustration left and table below) or the hook

dimension

C-2 in.

see Tab. 37, page 76, depending on which dimension is greater If

necessary turn setscrew (S1) to the right beforehand.

3.

Turn setscrew (S1) to the left until contact S1 switches audibly.

4.

Activate override button (S261) in control panel and at the same time

“down”

button

to leave the hoist limit switch area.

5.

Check cut-off point at fast and slow speed.

Wire rope hoist type

YK/SK

a [in]

50 Hz 60 Hz

1PS

1PD

5.1

5.9

2PS

2PD

2.8

3.1

4PS

1.6

2

Tab. 35