4

Installation

24

03.2018

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

4.3

Monorail trolleys

The trolleys are constructed according to the state of the art and supplied with mounted

buffers.

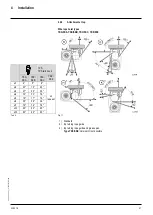

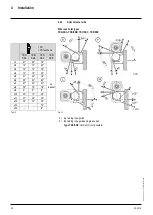

4.3.1

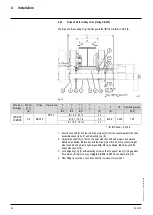

Monorail trolley (KE-S33 - 76)

with wire rope hoist types

YKA/SKA, YKB/SKB, YKC/SKC, YKD/SKD, YKE/SKE

Fig. 14

NOTICE

Material damage hazard.

If the flange width is altered (by customer), it may be

necessary to alter the counterweight to prevent the trolley canting.

Please have it checked by our after-sales service.

1.

Check flange width

“B”

and clearance

“c”

against Tab. 7 and set trolley to beam

width if necessary.

Installation if end of runway is freely accessible

1.

Slide trolley onto end of runway and check play

“

f/2

”

.

Installation if end of runway is not accessible

1.

Unscrew nuts (2) on threaded bolts (1) and slide trolley side cheek (3) outwards by

approx.

“

x

”

in.

or until dimension

B+y

is reached (Tab. 7).

2.

Push hoist side of trolley onto lower flange of runway beam and secure against

slipping.

3.

Push trolley side cheek (3) towards the runway beam on support bolt (4).

4.

Adjust dimension

“c”

with nuts (2), tighten nuts (2).

5.

Check track gage

“c”

and play

f/2

.

6.

Tighten nuts (2) with torque spanner to the specified tightening torque (see table

below).

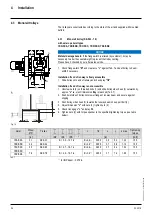

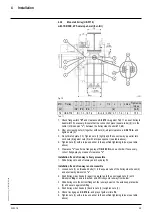

Hoist

Wheel

Ø D

Trolley

c

f/2

x

y

z max

Tightening

torque

[in]

INP

IPE

IPB

"

[in]

[lb

f

ft]

YKA/SKA

3.1

KE-S33

B = 3.5

…

19.7 in

B+2.6

1)

0.059

2.8

5.4

1.04

155

YKB/SKB

3.9

KE-S44

B+2.6

1)

0.059

3.1

5.8

1.12

155

YKC/SKC

5.5

KE-S65

B = 4.7…

19.7 in

B+2.6

1)

0.059

3.7

6.4

1.54

155

YKD/SKD

7.9

KE-S76

B = 4.9…19.7

in

B+3.6

1)

0.059

3.7

7.4

1.89

155

YKE/SKE

Tab. 7

1)

for INP beam: -0.079 in.