7

Inspection and maintenance

86

03.2018

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

7.16

Remaining service life

The operating mode and operating time must be established by the owner, see section

1.3 and recorded in the logbook in order to calculate the remaining service life.

After the service life has expired a general overhaul (S.W.P. = Safe Working Period) must

be carried out.

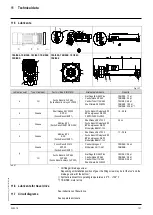

Fig. 101

7.16.1

Operating hours counter in SLE load monitor

The operating hours counter in the load monitor of the overload safety device adds up

the operating time of the hoist. In order to obtain the lifetime expired in full load hours, the

operating hours must

be calculated with load factor “k”

. This is carried out by a qualified

person

during the annual “

periodic inspection

”

.

If 90% of the theoretical full load lifetime has expired, a general overhaul (GO) must be

scheduled and carried out at the earliest possible date.

A general overhaul must be completed after 10 years at the latest.

7.16.2

SMC multi-controller (optional)

The operating time of the hoist and the full load operating hours are recorded in the SMC.

The SMC calculates the full load operating hours from the relevant hoisted load and the

operating hours of the hoist. The remaining service life is calculated with reference to the

mechanism group and can be read off by means of a PC (laptop).

If the theoretical full load lifetime has expired, also indicated by an illuminated red LED, a

general overhaul must be scheduled and carried out.

Reading the full load operating hours does not replace the prescribed tests

including inspecting the wearing parts (rope, return sheaves...).

.

7.17

General overhaul

The mechanism (motor and gear; not applicable to wearing parts) of the YK/SK wire rope

hoist is classified according to ISO. The theoretical full load lifetime in hours shown

opposite (D) is applicable for normal hoist applications.

ISO

M4

M5

M6

M7

D [h]

800

1600 3200 6400

Tab. 45

If the full load lifetime (D) minus the lifetime expired is nought, the wire rope hoist must

be overhauled by the manufacturer.

NOTICE

Danger of material damage.

Components which are in the power flux may only be

overhauled by the manufacturer.

The rope drive is classified according to FEM 9.661, see factory certificate.

As the service life of components such as gears is limited in accordance with the

classification, it must be ensured that this is not exceeded. After the scheduled service life

has expired hazards may arise. Thus the operator must take the responsibility for the

remaining service life and the necessity of a general overhaul.

We cannot accept any liability for damage occasioned by non-observance.