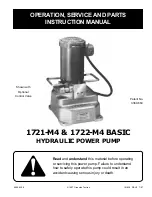

OPERATION MANUAL

OPERATION MANUAL

OPERATION MANUAL

OPERATION MANUAL

YAMADA AIR

YAMADA AIR

YAMADA AIR

YAMADA AIR----OPERATED DIAPHRAGM PUMPS

OPERATED DIAPHRAGM PUMPS

OPERATED DIAPHRAGM PUMPS

OPERATED DIAPHRAGM PUMPS

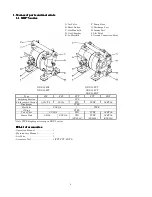

NDP-5 series

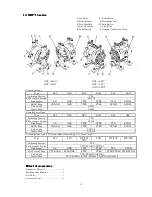

DP-10/12 series

NDP-10/12 series

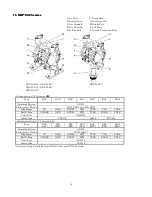

NDP-15 series

NDP-20 series

NDP-25 series

NDP-40 series

NDP-50 series

NDP-80 series

DP-F series

Doc. No.

NDP002U-18

Issue

1998-6

Revised

2008-12