1

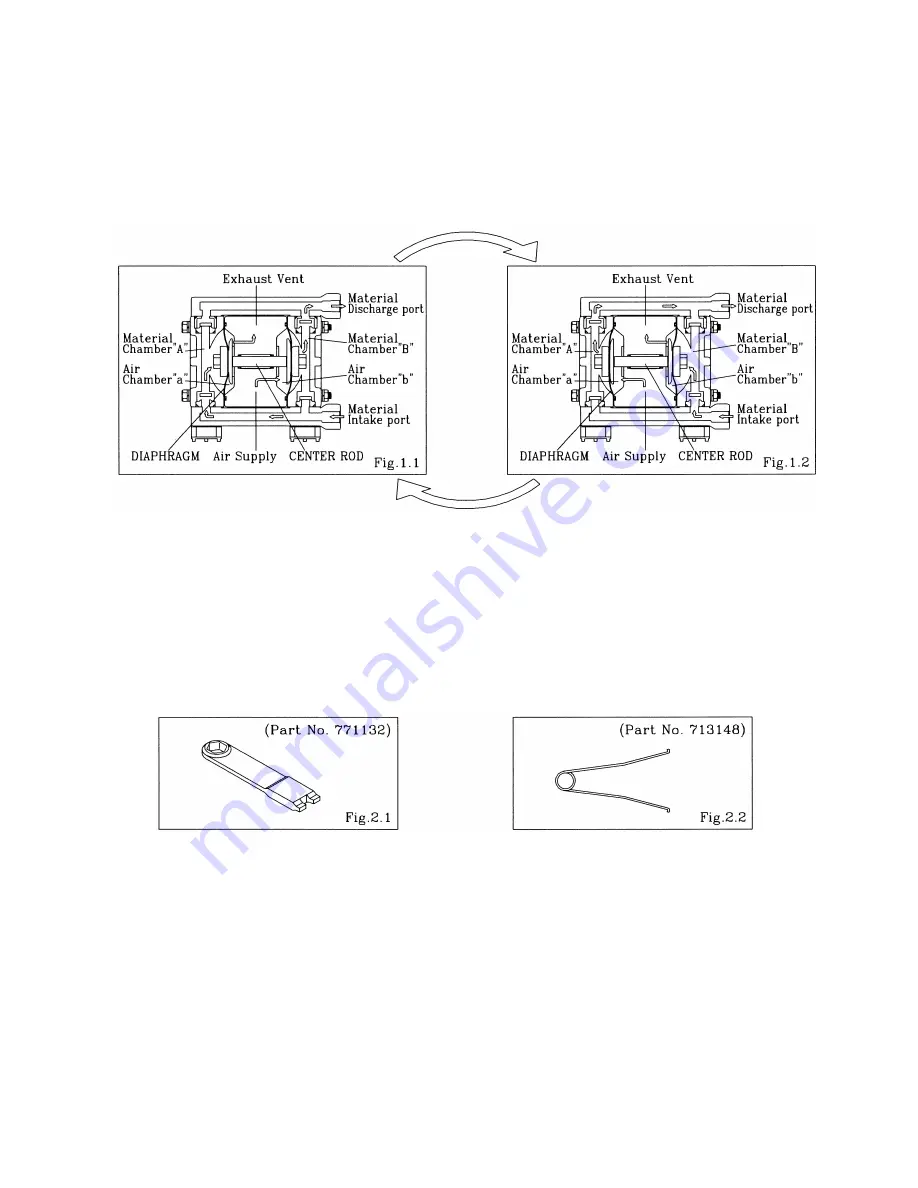

1.Principles of operation

There are two diaphragms fixed to the center rod, one at each end. When compressed air is supplied to air

chamber b (right side, see Fig. 1.1), the center rod moves to the right, the material in material chamber B

is pushed out, and at the same time material is sucked into material chamber A.

When the center rod is moved full-stroke to the right, the air switch valve is switched, compressed air is

sent to air chamber a (left side, see Fig.1.2), and the center rod moves to the left. The material in

material chamber A is pushed out, and at the same time material is sucked into material chamber B.

Through repetition of this operation, material is repeatedly taken in and discharged out.

2.Tools, etc.

2.1 General tools

▪

Socket wrenches

10mm( NDP-5 ), 13mm( NDP-15 )

▪

Open-end wrenches

10mm ( NDP-5 ), 13mm( NDP-15 ), 21mm( NDP-15 )

▪

Plyer

2.2 Special tools (sold separately)

▪

Cap and

disk remover

▪

Sleeve remover

Purpose: Removing the center disk of

Purpose: For removing sleeves

FP

□

and FVT and FDT types

2.3 Misc.

▪

Assembly oil

Turbine oil none addition class 1( equivalent to ISO VG32 grade )

▪

Nuts

M6

X

1( NDP-5 ), M8

X

1.25( NDP-15 )

▪

Grease

Urea grease grade (NLGI) No.2

3.Ordering Replacement parts

For accurate and speedy shipment of parts, be sure to order the right parts for your model to distributor

Indicate the part numbers, descriptions, and quantities.