6

Fig.5

5.

Maintenance and Inspection

5.1 Troubleshooting and Corrective Measures

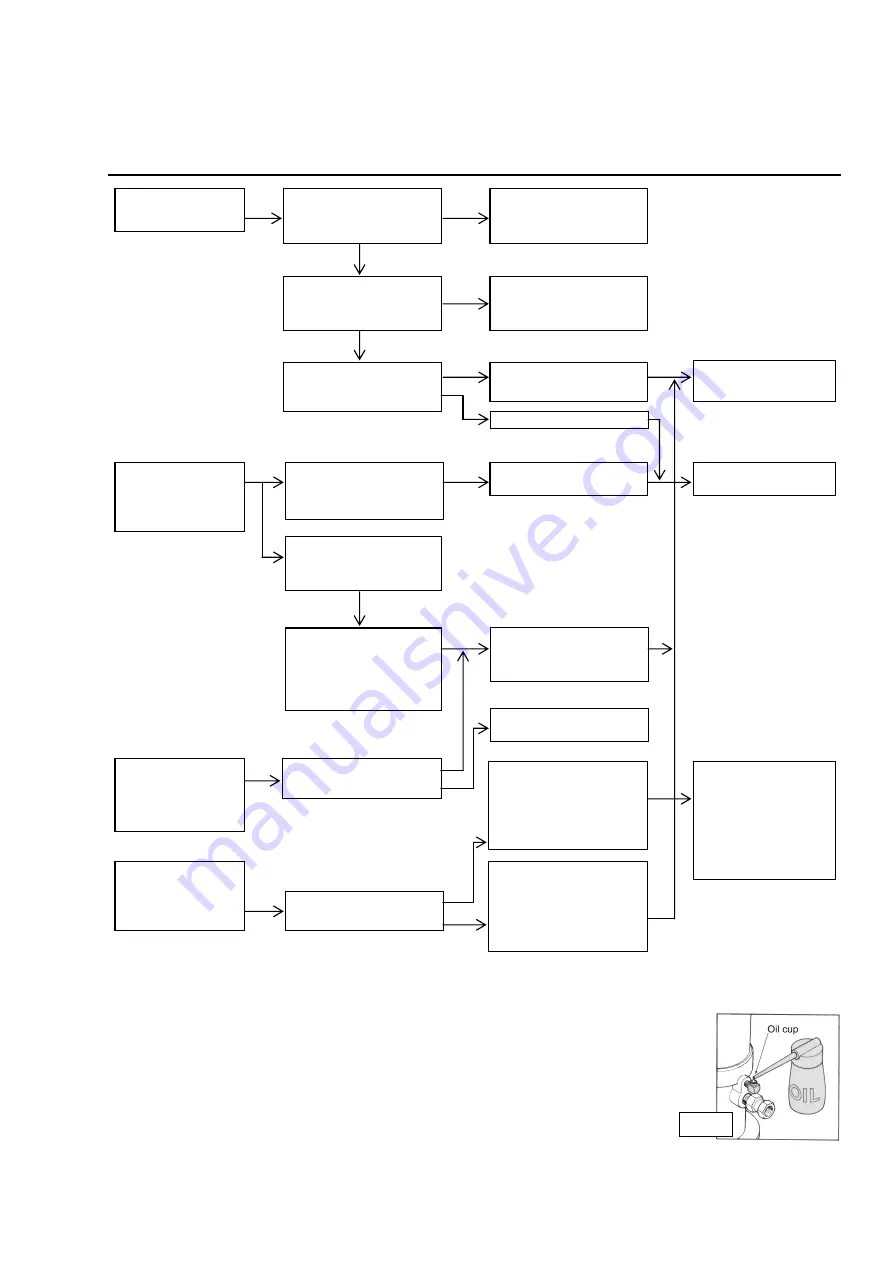

If the pump operation becomes unstable or trouble is caused to its grease discharge during

operation, make a check according to the following procedure.

Symptom Cause Contents of inspection and corrective measures

5.2 Maintenance and Inspection

For lubrication of the pump, perform oiling once every 10 days with lubricating oil. Supply the

lubricating oil as following. (Fig.5)

1) Remove the air regulator.

2) Inject a few drops of lubricating oil (approx. 0.5 mL) into the oil cup as

shown in the figure at right. Use turbine oil class 1 ISO (VG-32) or

equivalent as the lubricating oil.

5.3 Consumable Parts

The hose is a consumable part. Check it periodically. If any flaw or leak

is found, replace it a little early. The parts used in the packing and slide portion of the pump will be

worn away. They must be checked and replaced once a year.

The pump cannot

be operated.

Check if the air

regulator is normally

operated.

Check if the valve on

the outlet on the pump

side is not closed.

Remove the lower pump

and operate the air

motor independently.

Check if the valve in

the course of piping is

not closed.

Clogging occurs in the

connecting hose, pipe,

outlet valve, or gun.

The lower pump is

faulty.

The packing seal of the

air motor is worn away.

Ask for servicing the

lower pump

The pump is

continuously

operated without

stop.

Check if oil does not

leak at the exhaust

port.

Check if there is any

open valve on the

material output side.

The air motor is faulty.

Ask for servicing the

air motor.

When the outlet side is

closed, check if any leak

does not occur on the

pipe, connecting hose or

its connecting portion.

The valve of the lower

pump or the packing is

worn away.

The pump can be

operated but grease

is not fed by

pressure.

The pump can be

operated but the

discharge volume is

insufficient.

Is the oil included in the

container

Check if the supply air

pressure is not lowered.

Check and re-supply, or

replace.

The air supply

volume to the pump

is insufficient.

Replace the air hose

with a thicker one or

check the air

compressor.

check

check

operable

inoperable

Increase the pressure

up to 0.7 MPa by the air

regulator. At this time,

the oil volume does not

reach the specified level.

The valve seat surface

of the lower pump is

worn away or clogging

is caused by dust or

foreign substances.

NO

YES

YES

NO

YES

NO

NO