6 - 8

FUEL

CARBURETOR

DISASSEMBLING THE CARBURETOR

NOTE:

Before disassembling the carburetor, make

sure to note the number of times the pilot

screw is turned out from the seated position to

its set position.

CHECKING THE CARBURETOR

1. Check:

• carburetor body

• float chamber

Cracks/damage

→

Replace.

• fuel passage

Contamination

→

Clean as indicated.

• fuel chamber body

Contamination

→

Clean.

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

a. Wash the carburetor in a petroleum based

solvent.

(Do not use any caustic carburetor cleaning

solution.)

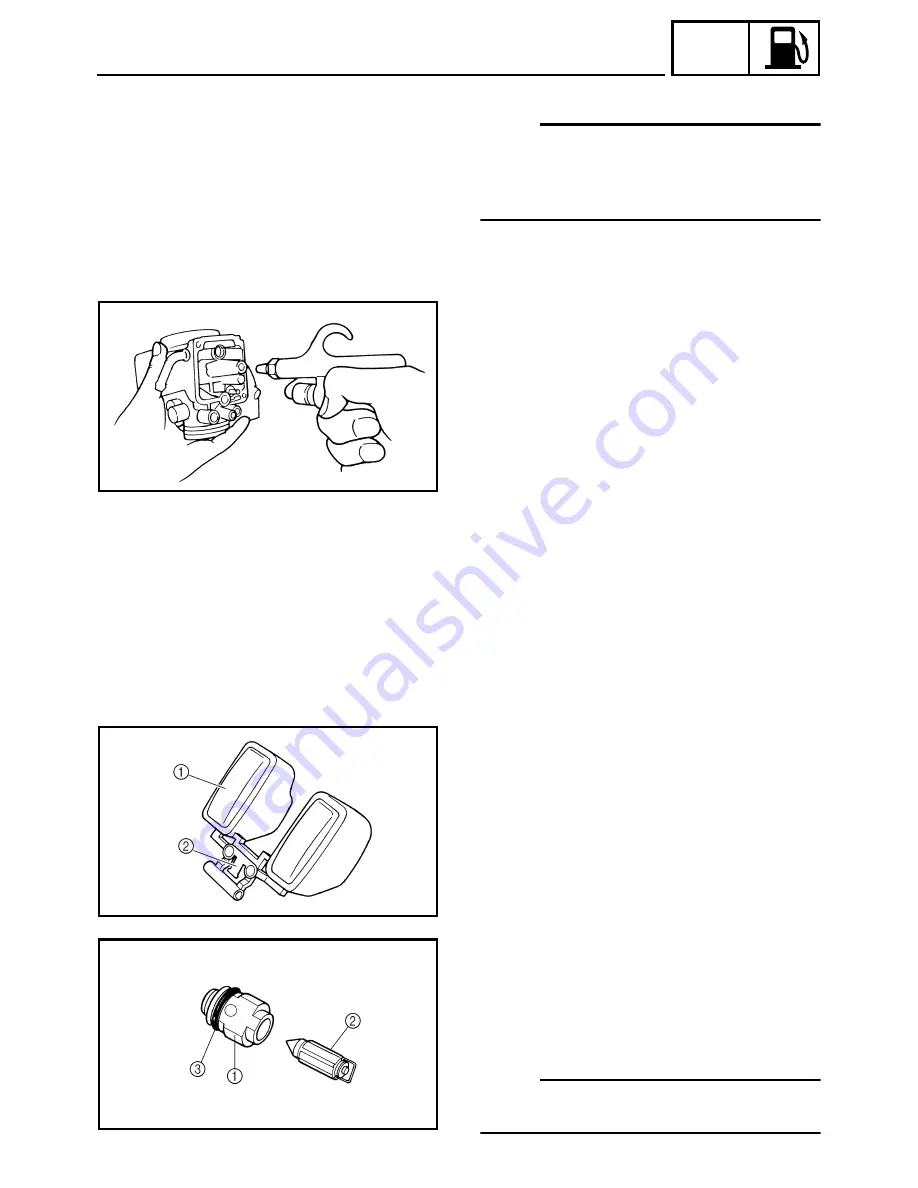

b. Blow out all of the passages and jets with

compressed air.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

2. Check:

• float

1

• float tang

2

Damage

→

Replace.

3. Check:

• needle valve seat

1

• needle valve

2

• O-ring

3

Contamination/wear/damage

→

Replace as

a set.

NOTE:

Always replace the needle valve and valve

seat as a set.

Summary of Contents for 2004 Rhino 660 YXR660FAS

Page 1: ...LIT 11616 17 23 5UG F8197 10 YXR660FAS SERVICE MANUAL ...

Page 6: ......

Page 40: ...2 11 SPEC ENGINE SPECIFICATIONS Cylinder head tightening sequence ...

Page 55: ...2 26 SPEC COOLANT FLOW DIAGRAMS 1 Coolant outlet hose 2 Radiator inlet pipe 2 1 ...

Page 383: ...9 31 ELEC LIGHTING SYSTEM ...

Page 418: ......

Page 419: ......

Page 420: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...