7 - 16

DRIV

FRONT CONSTANT VELOCITY JOINTS, DIFFERENTIAL

GEAR AND DRIVE SHAFT

2. Adjust:

• gear lash

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

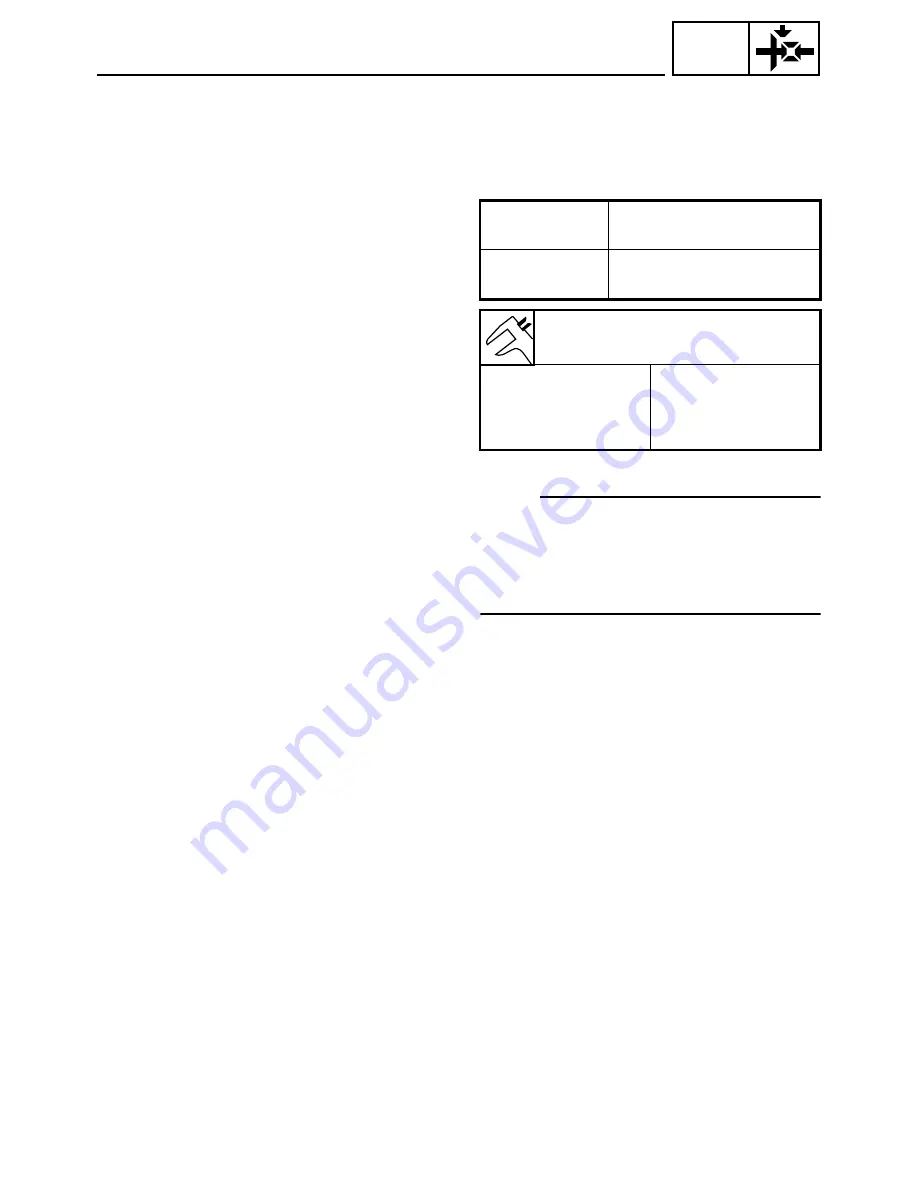

a. Select the suitable shims using the following

chart.

* right shim only

NOTE:

• Use a combination of shims (left and right) so

that the differential gear lash is within specifi-

cation.

• Always keep the total combined thickness of

the shims (left and right) the same.

Example:

If the differential gear lash exceeds the specifi-

cation, increase the thickness of the right

shim(s) by 0.1 mm (0.004 in) and decrease the

thickness of the left shim(s) by 0.1 mm

(0.004 in).

b. Measure the differential gear lash again.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

Too little gear

lash

Reduce right shim

thickness.

Too large

gear lash

Increase right shim

thickness.

Ring gear shim (left and right)

Thickness (mm)

0.1

0.5

0.2

1.0

0.3

1.5*

0.4

CHECKING THE DIFFERENTIAL GEAR

OPERATION

1. Block the rear wheels, and elevate the front

wheels by placing a suitable stand under

the frame.

2. Remove the center cap from the axle nut

(right or left).

Summary of Contents for 2004 Rhino 660 YXR660FAS

Page 1: ...LIT 11616 17 23 5UG F8197 10 YXR660FAS SERVICE MANUAL ...

Page 6: ......

Page 40: ...2 11 SPEC ENGINE SPECIFICATIONS Cylinder head tightening sequence ...

Page 55: ...2 26 SPEC COOLANT FLOW DIAGRAMS 1 Coolant outlet hose 2 Radiator inlet pipe 2 1 ...

Page 383: ...9 31 ELEC LIGHTING SYSTEM ...

Page 418: ......

Page 419: ......

Page 420: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...