5-67

CRANKSHAFT

EAS00388

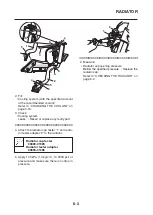

REMOVING THE CRANKSHAFT

ASSEMBLY

1. Remove:

• Crankshaft “1”

NOTE:

• Remove the crankshaft with the crankcase

separating tool “2”.

• Make sure the crankcase separating tool is

centered over the crankshaft.

Crankcase separating tool

90890-01135

EAS00394

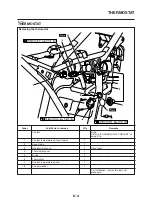

CHECKING THE CRANKSHAFT

1. Measure:

• Big end side clearance “d”

Out of specification

→

Replace the big end

bearing, crankshaft pin, or connecting rod.

1

2

Big end side clearance

0.350-0.650 mm

(0.0138-0.0256 in)

2. Measure:

• Crankshaft width “a”

Out of specification

→

Replace the crank-

shaft.

Crankshaft width

74.95-75.00 mm

(2.9508-2.9528 in)

3. Measure:

• Crankshaft runout “c”

Out of specification

→

Replace the crank-

shaft, bearing or both.

NOTE:

Turn the crankshaft slowly.

a. The crankshaft “1” and the crankshaft pin “2”

oil passages must be properly interconnect-

ed with a tolerance of less than 1 mm

(0.04 in).

4. Check:

• Crankshaft sprocket

Damage/wear

→

Replace the crankshaft.

• Bearing

Cracks/damage/wear

→

Replace the crank-

shaft.

5. Check:

• Crankshaft journal

Scratches/wear

→

Replace the crankshaft.

• Crankshaft journal oil passage

Obstruction

→

Blow out with compressed air.

1

2

Maximum crankshaft runout

0.04 mm (0.0016 in)

c

d

c

a

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Summary of Contents for 2008 Tenere

Page 1: ...SERVICE MANUAL 2008 11D F8197 E0 XT660Z ...

Page 8: ......

Page 24: ......

Page 44: ...2 20 TIGHTENING TORQUES Cylinder head tightening sequence 2 4 3 1 ...

Page 54: ...2 30 COOLING SYSTEM DIAGRAMS 1 2 3 4 5 6 7 9 10 11 12 5 8 11 A ...

Page 57: ...2 33 LUBRICATION DIAGRAMS LUBRICATION DIAGRAMS 1 A A A A B B B A A B 3 2 2 4 1 1 5 5 ...

Page 59: ...2 35 LUBRICATION DIAGRAMS A A A A 3 1 2 3 4 ...

Page 60: ...2 36 LUBRICATION DIAGRAMS 1 Oil delivery pipe 2 2 Oil delivery pipe 1 3 Oil filter 4 Oil pump ...

Page 61: ...2 37 LUBRICATION DIAGRAMS 1 7 2 3 4 5 6 A ...

Page 63: ...2 39 LUBRICATION DIAGRAMS 1 6 5 4 3 2 ...

Page 65: ...2 41 CABLE ROUTING CABLE ROUTING ...

Page 67: ...2 43 CABLE ROUTING ...

Page 69: ...2 45 CABLE ROUTING ...

Page 71: ...2 47 CABLE ROUTING ...

Page 73: ...2 49 CABLE ROUTING ...

Page 75: ...2 51 CABLE ROUTING ...

Page 77: ...2 53 CABLE ROUTING ...

Page 79: ...2 55 CABLE ROUTING ...

Page 81: ...2 57 CABLE ROUTING ...

Page 83: ...2 59 CABLE ROUTING ...

Page 176: ...4 56 FRONT FORK WARNING Make sure the brake hoses are routed prop erly 1 2 3 ...

Page 270: ......

Page 284: ......

Page 301: ...7 17 FUEL INJECTION SYSTEM WIRING DIAGRAM ...

Page 324: ......

Page 327: ...8 1 IGNITION SYSTEM EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 331: ...8 5 ELECTRIC STARTING SYSTEM EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 337: ...8 11 CHARGING SYSTEM EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 338: ...8 12 CHARGING SYSTEM 2 A C magneto 5 Rectifier regulator 7 Battery 8 Main fuse ...

Page 340: ...8 14 CHARGING SYSTEM ...

Page 341: ...8 15 LIGHTING SYSTEM EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 345: ...8 19 SIGNALING SYSTEM EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 351: ...8 25 COOLING SYSTEM EAS00807 COOLING SYSTEM CIRCUIT DIAGRAM ...

Page 354: ...8 28 COOLING SYSTEM ...

Page 355: ...8 29 IMMOBILIZER SYSTEM ET5YU1002 IMMOBILIZER SYSTEM ET5YU1003 CIRCUIT DIAGRAM ...

Page 364: ...8 38 IMMOBILIZER SYSTEM ...

Page 365: ...8 39 ELECTRICAL COMPONENTS EAS27970 ELECTRICAL COMPONENTS ...

Page 367: ...8 41 ELECTRICAL COMPONENTS ...

Page 369: ...8 43 ELECTRICAL COMPONENTS EAS27980 CHECKING THE SWITCHES ...

Page 388: ......

Page 390: ......

Page 396: ...COLOR CODE ...

Page 397: ......

Page 398: ...YAMAHA MOTOR ITALIA S P A ...

Page 399: ...XT660Z 2008 WIRING DIAGRAM ...