PERIODIC MAINTENANCE

3-2

EAS4D3F012

GENERAL MAINTENANCE AND LUBRICATION CHART

NO.

ITEM

CHECK OR MAINTENANCE

JOB

Whichever

comes first

INITIAL

EVERY

month

1

3

6

6

12

km

(mi)

320

(200)

1300

(800)

2500

(1600)

2500

(1600)

5000

(3200)

hours

20

80

160

160

320

1

Air filter element

• Clean and replace if necessary.

Every 20–40 hours (more often in wet or

dusty areas)

2 * Clutch

• Check operation and adjust if necessary.

√

√

√

√

3 * Front brake

• Check operation and correct if necessary.

• Check fluid level and ATV for fluid leakage, and correct

necessary.

√

√

√

√

√

• Replace brake pads.

Whenever worn to the limit

4 * Rear brake

• Check operation and correct if necessary.

• Check fluid level and ATV for fluid leakage, and correct

necessary.

√

√

√

√

√

• Replace brake pads.

Whenever worn to the limit

5 * Brake hoses

• Check for cracks or other damage, and replace if neces-

sary.

√

√

√

√

• Replace.

Every 4 years

6 * Parking brake

• Check operation and adjust if necessary.

√

√

√

√

√

7 * Wheels

• Check runout and for damage, and replace if necessary.

√

√

√

√

8 * Tires

• Check tread depth and for damage, and replace if neces-

sary.

• Check air pressure and balance, and correct if necessary.

√

√

√

√

9 *

Wheel hub bear-

ings

• Check for looseness or damage, and replace if necessary.

√

√

√

√

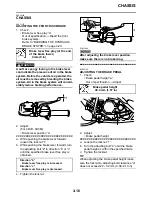

10 * Swingarm pivots

• Check operation and for excessive play, and replace bear-

ings if necessary.

• Lubricate with lithium-soap-based grease.

√

√

√

11 *

Upper and lower

arm pivots

• Lubricate with lithium-soap-based grease.

√

√

√

12

Drive chain

• Check chain slack and adjust if necessary.

• Check rear wheel alignment and correct if necessary.

• Clean and lubricate.

√

√

√

√

√

13 * Drive chain rollers

• Check for wear and replace if necessary.

√

√

√

14 * Chassis fasteners

• Make sure that all nuts, bolts, and screws are properly

tightened.

√

√

√

√

√

15 *

Shock absorber

assemblies

• Check operation and correct if necessary.

• Check for oil leakage and replace if necessary.

√

√

√

16 *

Rear suspension

relay arm and con-

necting arm pivot-

ing points

• Check operation and correct if necessary.

• Lubricate with lithium-soap-based grease.

√

√

√

√

17 * Steering shaft

• Lubricate with lithium-soap-based grease.

√

√

√

18 * Steering system

• Check operation and repair or replace if damaged.

• Check toe-in and adjust if necessary.

√

√

√

√

√

19 * Engine mount

• Check for cracks or other damage, and replace if neces-

sary.

√

√

√

20

Engine oil

• Change.

• Check ATV for oil leakage, and correct if necessary.

√

√

√

√

21

Engine oil filter

element

• Clean or replace if necessary.

√

√

√

22 *

Moving parts and

cables

• Lubricate.

√

√

√

√

23 *

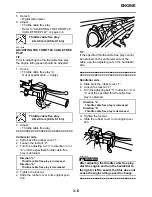

Throttle lever

housing and cable

• Check operation and correct if necessary.

• Check throttle cable free play and adjust if necessary.

• Lubricate throttle lever housing and cable.

√

√

√

√

√

24 *

Front and rear

brake switches

• Check operation and correct if necessary.

√

√

√

√

√

Summary of Contents for 2009 YFM25RY

Page 1: ...SERVICE MANUAL YFM25RY YFM25RSEY YFM25RSE2Y 4D3 28197 11 LIT 11616 22 09 2009 ...

Page 8: ......

Page 39: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 20 ...

Page 42: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 23 EAS20410 LUBRICATION DIAGRAMS ...

Page 44: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25 ...

Page 46: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 ...

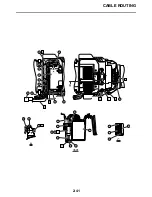

Page 47: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 28 1 Oil cooler 2 Oil hose 1 3 Oil hose 2 ...

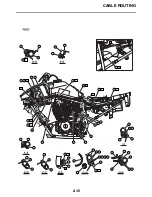

Page 48: ...CABLE ROUTING 2 29 EAS20430 CABLE ROUTING ...

Page 50: ...CABLE ROUTING 2 31 ...

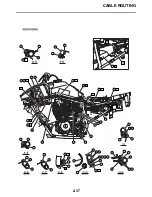

Page 52: ...CABLE ROUTING 2 33 ...

Page 54: ...CABLE ROUTING 2 35 ...

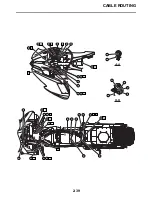

Page 56: ...CABLE ROUTING 2 37 ...

Page 58: ...CABLE ROUTING 2 39 ...

Page 60: ...CABLE ROUTING 2 41 ...

Page 62: ...CABLE ROUTING 2 43 ...

Page 65: ......

Page 143: ...HANDLEBAR 4 42 Throttle cable free play 2 0 4 0 mm 0 08 0 16 in ...

Page 162: ...CHAIN DRIVE 4 61 ...

Page 165: ......

Page 240: ...CARBURETOR 6 9 ...

Page 242: ...IGNITION SYSTEM 7 1 EAS27090 IGNITION SYSTEM EAS27100 CIRCUIT DIAGRAM ...

Page 246: ...ELECTRIC STARTING SYSTEM 7 5 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 252: ...CHARGING SYSTEM 7 11 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 255: ...CHARGING SYSTEM 7 14 ...

Page 256: ...LIGHTING SYSTEM 7 15 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 260: ...SIGNALING SYSTEM 7 19 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 264: ...CARBURETOR HEATING SYSTEM 7 23 EAS27490 CARBURETOR HEATING SYSTEM EAS27500 CIRCUIT DIAGRAM ...

Page 267: ...CARBURETOR HEATING SYSTEM 7 26 ...

Page 268: ...ELECTRICAL COMPONENTS 7 27 EAS27972 ELECTRICAL COMPONENTS ...

Page 270: ...ELECTRICAL COMPONENTS 7 29 EAS27980 CHECKING THE SWITCHES ...

Page 284: ...ELECTRICAL COMPONENTS 7 43 ...

Page 291: ......

Page 292: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...

Page 293: ...WIRING DIAGRAM YFM25RY YFM25RSEY YFM25RSE2Y ...