CHASSIS

3-21

k. Fill the brake fluid reservoir to the proper

level with the recommended brake fluid.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-17.

WARNING

EWA13110

After bleeding the hydraulic brake system,

check the brake operation.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS4D3F004

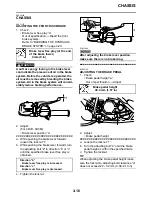

ADJUSTING THE SHIFT PEDAL

1. Measure:

• Shift pedal height “a”

Out of specification

→

Adjust.

2. Adjust:

• Shift pedal position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the drive sprocket cover “1”.

Refer to “CHAIN DRIVE” on page 4-57.

b. Remove the bolt “2”.

c. Remove the shift pedal “3”.

d. Install the shift pedal at the correct height.

e. Tighten the bolt to specification.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS21390

ADJUSTING THE DRIVE CHAIN SLACK

TIP

• Measure the drive chain slack halfway

between the drive axle and the rear axle.

• When checking and adjusting the drive chain

slack, there should be no weight on the vehi-

cle and all tires must be touching the ground.

ECA13550

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Check:

• Drive chain slack “a”

Out of specification

→

Adjust.

2. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

TIP

The drive chain slack is adjusted by the rota-

tion of the rear axle hub.

a. Loosen the rear axle pinch bolts “1”.

b. Insert a rod of a diameter of 8 mm (0.31 in)

and length of 10 cm (4 in) “2” in the hole “3”

of rear axle hub “4”.

c. Shift the transmission into the neutral posi-

tion.

d. To loosen the drive chain, push the vehicle

forward and to tighten the drive chain, pull

the vehicle backward.

Shift pedal height

15.2 mm (0.60 in)

Shift pedal bolt

10 Nm (1.0 m·kg, 7.4 ft·lb)

Drive chain slack

45.0–55.0 mm (1.77–2.17 in)

Summary of Contents for 2009 YFM25RY

Page 1: ...SERVICE MANUAL YFM25RY YFM25RSEY YFM25RSE2Y 4D3 28197 11 LIT 11616 22 09 2009 ...

Page 8: ......

Page 39: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 20 ...

Page 42: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 23 EAS20410 LUBRICATION DIAGRAMS ...

Page 44: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25 ...

Page 46: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 ...

Page 47: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 28 1 Oil cooler 2 Oil hose 1 3 Oil hose 2 ...

Page 48: ...CABLE ROUTING 2 29 EAS20430 CABLE ROUTING ...

Page 50: ...CABLE ROUTING 2 31 ...

Page 52: ...CABLE ROUTING 2 33 ...

Page 54: ...CABLE ROUTING 2 35 ...

Page 56: ...CABLE ROUTING 2 37 ...

Page 58: ...CABLE ROUTING 2 39 ...

Page 60: ...CABLE ROUTING 2 41 ...

Page 62: ...CABLE ROUTING 2 43 ...

Page 65: ......

Page 143: ...HANDLEBAR 4 42 Throttle cable free play 2 0 4 0 mm 0 08 0 16 in ...

Page 162: ...CHAIN DRIVE 4 61 ...

Page 165: ......

Page 240: ...CARBURETOR 6 9 ...

Page 242: ...IGNITION SYSTEM 7 1 EAS27090 IGNITION SYSTEM EAS27100 CIRCUIT DIAGRAM ...

Page 246: ...ELECTRIC STARTING SYSTEM 7 5 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 252: ...CHARGING SYSTEM 7 11 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 255: ...CHARGING SYSTEM 7 14 ...

Page 256: ...LIGHTING SYSTEM 7 15 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 260: ...SIGNALING SYSTEM 7 19 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 264: ...CARBURETOR HEATING SYSTEM 7 23 EAS27490 CARBURETOR HEATING SYSTEM EAS27500 CIRCUIT DIAGRAM ...

Page 267: ...CARBURETOR HEATING SYSTEM 7 26 ...

Page 268: ...ELECTRICAL COMPONENTS 7 27 EAS27972 ELECTRICAL COMPONENTS ...

Page 270: ...ELECTRICAL COMPONENTS 7 29 EAS27980 CHECKING THE SWITCHES ...

Page 284: ...ELECTRICAL COMPONENTS 7 43 ...

Page 291: ......

Page 292: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...

Page 293: ...WIRING DIAGRAM YFM25RY YFM25RSEY YFM25RSE2Y ...