4-7

CHASSIS

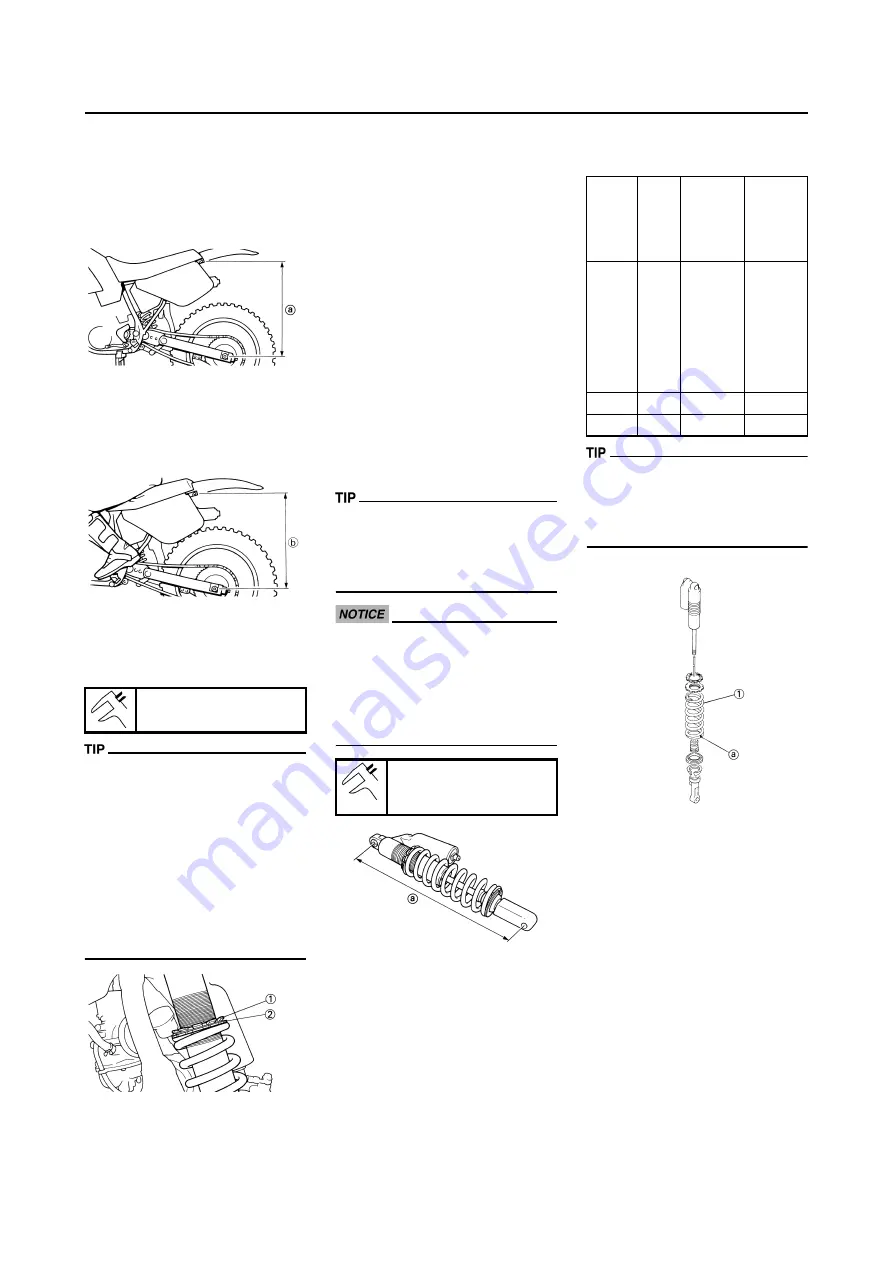

CHOOSING SET LENGTH

1. Place a stand or block under the

engine to put the rear wheel

above the floor, and measure the

length "a" between the rear wheel

axle center and the rear fender

holding bolt.

2. Remove the stand or block from

the engine and with a rider astride

the seat, measure the sunken

length "b" between the rear wheel

axle center and the rear fender

holding bolt.

3. Loosen the locknut "1" and make

adjustment by turning the spring

adjuster "2" to achieve the stan-

dard figure from the subtraction of

the length "b" from the length "a".

• If the machine is new and after it is

broken in, the same set length of

the spring may change because of

the initial fatigue, etc. of the spring.

Therefore, be sure to make reeval-

uation.

• If the standard figure cannot be

achieved by adjusting the spring

adjuster and changing the spring

set length, replace the spring with

an optional one and make re-ad-

justment.

SETTING OF SPRING AFTER

REPLACEMENT

After replacement, be sure to adjust

the spring to the set length [sunken

length 90–100 mm (3.5–3.9 in)] and

set it.

1. Use of soft spring

• Set the soft spring for less re-

bound damping to compensate

for its less spring load. Run with

the rebound damping adjuster

one or two clicks on the softer

side and readjust it to suit your

preference.

2. Use of stiff spring

• Set the soft spring for more re-

bound damping to compensate

for its greater spring load. Run

with the rebound damping adjust-

er one or two clicks on the stiffer

side and readjust it to suit your

preference.

Adjusting the rebound damping will

be followed more or less by a change

in the compression damping. For cor-

rection, turn the low compression

damping adjuster on the softer side.

When using a rear shock absorber

other than currently installed, use

the one whose overall length "a"

does not exceed the standard as it

may result in faulty performance.

Never use one whose overall

length is greater than standard.

REAR SHOCK ABSORBER

SETTING PARTS

• Rear shock spring "1"

• The I.D. mark "a" is marked at the

end of the spring.

• Spring specification varies accord-

ing to the color and quantity of I.D.

marks.

Standard figure:

90–100 mm (3.5–3.9 in)

Length "a" of standard

shock:

488.5 mm (19.23 in)

TYPE

SPRI

NG

RAT

E

SPRING

PART

NUM-

BER

(-22212-)

I.D.

MARK/

Q'TY

SOFT

4.3

5UN-00

Brown/1

4.5

5UN-10

Green/1

4.7

5UN-20

Red/1

4.9

5UN-30

Black/1

5.1

5UN-40

Blue/1

5.3

5UN-50

Yellow/1

STD

5.5

5UN-60

Pink/1

STIFF

5.7

5UN-70

White/1

Summary of Contents for 2010 WR450FZ

Page 4: ......

Page 12: ...1 2 LOCATION OF IMPORTANT LABELS EUROPE ...

Page 13: ...1 3 LOCATION OF IMPORTANT LABELS AUS NZ ZA ...

Page 49: ...2 18 TIGHTENING TORQUES ...

Page 51: ...2 20 LUBRICATION DIAGRAMS 1 Intake camshaft 2 Exhaust camshaft A To main axle B From oil pump ...

Page 90: ...3 31 ELECTRICAL Charging method using a variable voltage charger ...

Page 91: ...3 32 ELECTRICAL Charging method using a constant voltage charger ...

Page 125: ...5 22 CYLINDER HEAD 3 Install Bolt cylinder head 1 Bolt cylinder head 10 Nm 1 0 m kg 7 2 ft lb ...

Page 144: ...5 41 OIL PUMP 15 Oil pump drive shaft 1 16 Rotor housing 1 Order Part name Q ty Remarks ...