5-46

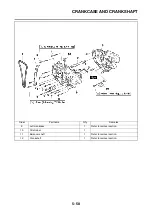

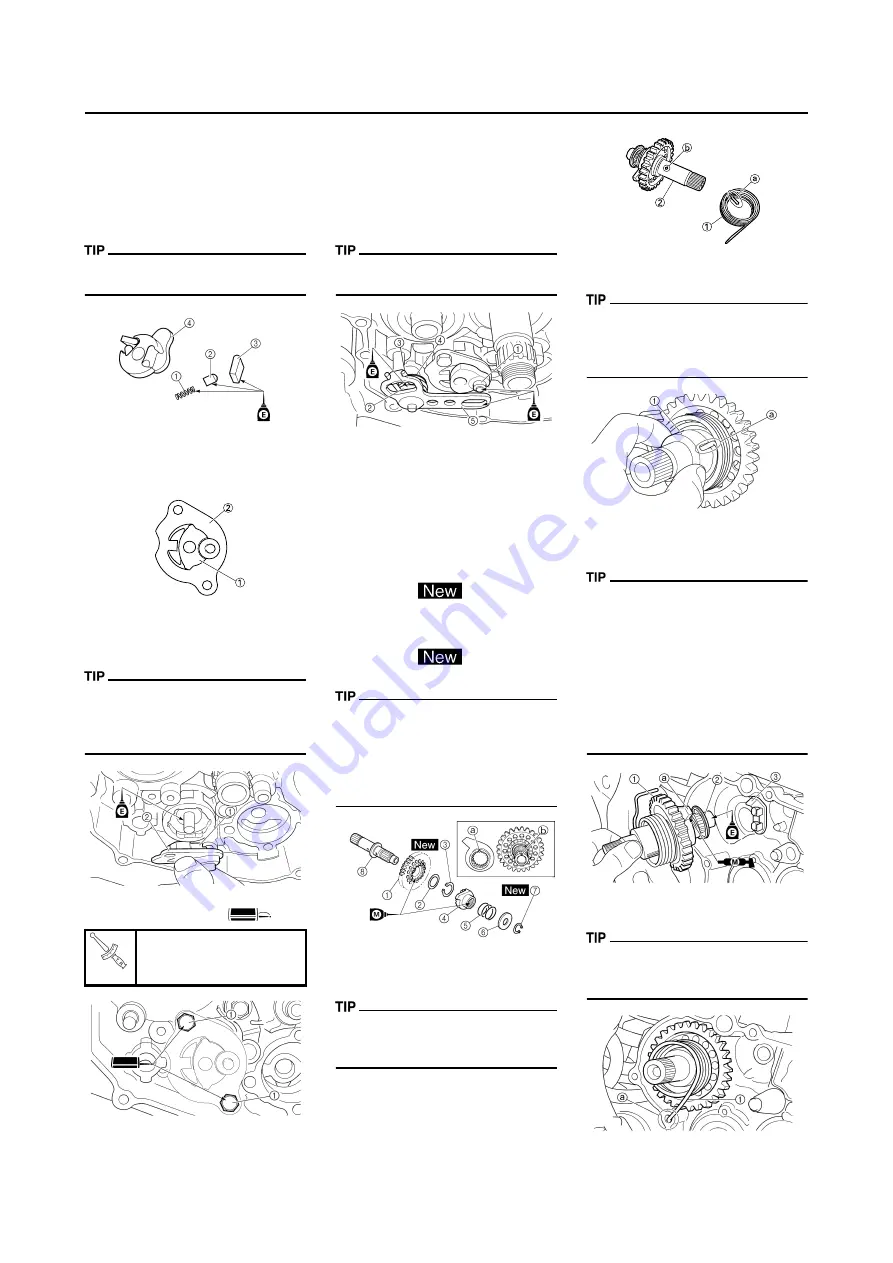

KICK SHAFT AND SHIFT SHAFT

INSTALLING THE SHIFT GUIDE

AND SHIFT LEVER ASSEMBLY

1. Install:

• Spring "1"

• Pawl pin "2"

• Pawl "3"

To shift lever "4".

Apply the engine oil on the spring,

pawl pin and pawl.

2. Install:

• Shift lever assembly "1"

To shift guide "2".

3. Install:

• Shift lever assembly "1"

• Shift guide "2"

• The shift lever assembly is installed

at the same time as the shift guide.

• Apply the engine oil on the bolt

(segment) shaft.

4. Install:

• Bolt (shift guide) "1"

INSTALLING THE SHIFT SHAFT

1. Install:

• Roller "1"

• Collar "2"

• Torsion spring "3"

• Washer "4"

• Shift shaft "5"

Apply the engine oil on the roller and

shift shaft.

2. Install:

• Shift pedal

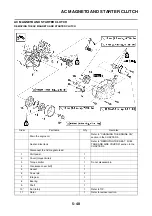

Refer to "AC MAGNETO AND

STARTER CLUTCH" section.

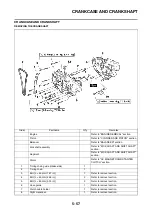

INSTALLING THE KICK SHAFT

ASSEMBLY

1. Install:

• Kick gear "1"

• Washer "2"

• Circlip "3"

• Ratchet wheel "4"

• Spring "5"

• Washer "6"

• Circlip "7"

To kick shaft "8".

• Apply the molybdenum disulfide oil

on the inner circumferences of the

kick gear and ratchet wheel.

• Align the punch mark "a" on the

ratchet wheel with the punch mark

"b" on the kick shaft.

2. Install:

• Torsion spring "1"

To kick shaft "2".

Make sure the stopper "a" of the tor-

sion spring fits into the hole "b" on the

kick shaft.

3. Install:

• Spring guide "1"

Slide the spring guide into the kick

shaft, make sure the groove "a" in the

spring guide fits on the stopper of the

torsion spring.

4. Install:

• Kick shaft assembly "1"

• Washer "2"

• Apply the molybdenum disulfide

grease on the contacting surfaces

of the kick shaft stopper "a" and kick

shaft ratchet wheel guide "3".

• Apply the engine oil on the kick

shaft.

• Slide the kick shaft assembly into

the crankcase and make sure the

kick shaft stopper "a" fits into the

kick shaft ratchet wheel guide.

5. Hook:

• Torsion spring "1"

Turn the torsion spring clockwise and

hook into the proper hole "a" in the

crankcase.

Bolt (shift guide):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Summary of Contents for 2010 WR450FZ

Page 4: ......

Page 12: ...1 2 LOCATION OF IMPORTANT LABELS EUROPE ...

Page 13: ...1 3 LOCATION OF IMPORTANT LABELS AUS NZ ZA ...

Page 49: ...2 18 TIGHTENING TORQUES ...

Page 51: ...2 20 LUBRICATION DIAGRAMS 1 Intake camshaft 2 Exhaust camshaft A To main axle B From oil pump ...

Page 90: ...3 31 ELECTRICAL Charging method using a variable voltage charger ...

Page 91: ...3 32 ELECTRICAL Charging method using a constant voltage charger ...

Page 125: ...5 22 CYLINDER HEAD 3 Install Bolt cylinder head 1 Bolt cylinder head 10 Nm 1 0 m kg 7 2 ft lb ...

Page 144: ...5 41 OIL PUMP 15 Oil pump drive shaft 1 16 Rotor housing 1 Order Part name Q ty Remarks ...