5-60

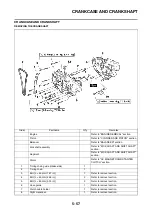

CRANKCASE AND CRANKSHAFT

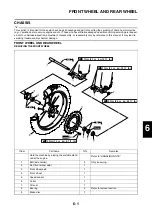

DISASSEMBLING THE

CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

Separation steps:

a. Remove the crankcase bolts,

hose guide and clutch cable hold-

er.

Loosen each bolt 1/4 of a turn at a

time and after all the bolts are loos-

ened, remove them.

b. Remove the right crankcase.

• Place the crankcase with its left

side downward and split it by insert-

ing a screwdriver tip into the split-

ting slit "a" in the crankcase.

• Lift the right crankcase horizontally

while lightly patting the case split-

ting slit and engine mounting boss

using a soft hammer, and leave the

crankshaft and transmission with

the left crankcase.

Use soft hammer to tap on the

case half. Tap only on reinforced

portions of case. Do not tap on

gasket mating surface. Work slow-

ly and carefully. Make sure the

case halves separate evenly. If the

cases do not separate, check for a

remaining case bolt or fitting. Do

not force.

c. Remove the dowel pins and O-

ring.

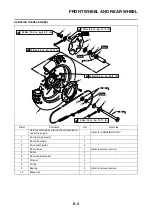

REMOVING THE BALANCER

SHAFT

1. Remove:

• Balancer shaft "1"

Remove the balancer shaft with its

flat side "a" facing the crankshaft.

REMOVING THE CRANKSHAFT

1. Remove:

• Crankshaft "1"

Use the crankcase separating

tool "2".

Install the crankcase separating tool

as shown.

Do not use a hammer to drive out

the crankshaft.

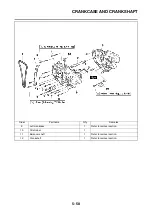

REMOVING THE CRANKCASE

BEARING

1. Remove:

• Bearing "1"

• Remove the bearing from the

crankcase by pressing its inner

race.

• Do not use the removed bearing.

CHECKING THE TIMING CHAIN

AND TIMING CHAIN GUIDE

1. Inspect:

• Timing chain

Cracks/stiff

→

Replace the timing

chain and camshaft sprocket as a

set.

2. Inspect:

• Timing chain guide

Wear/damage

→

Replace.

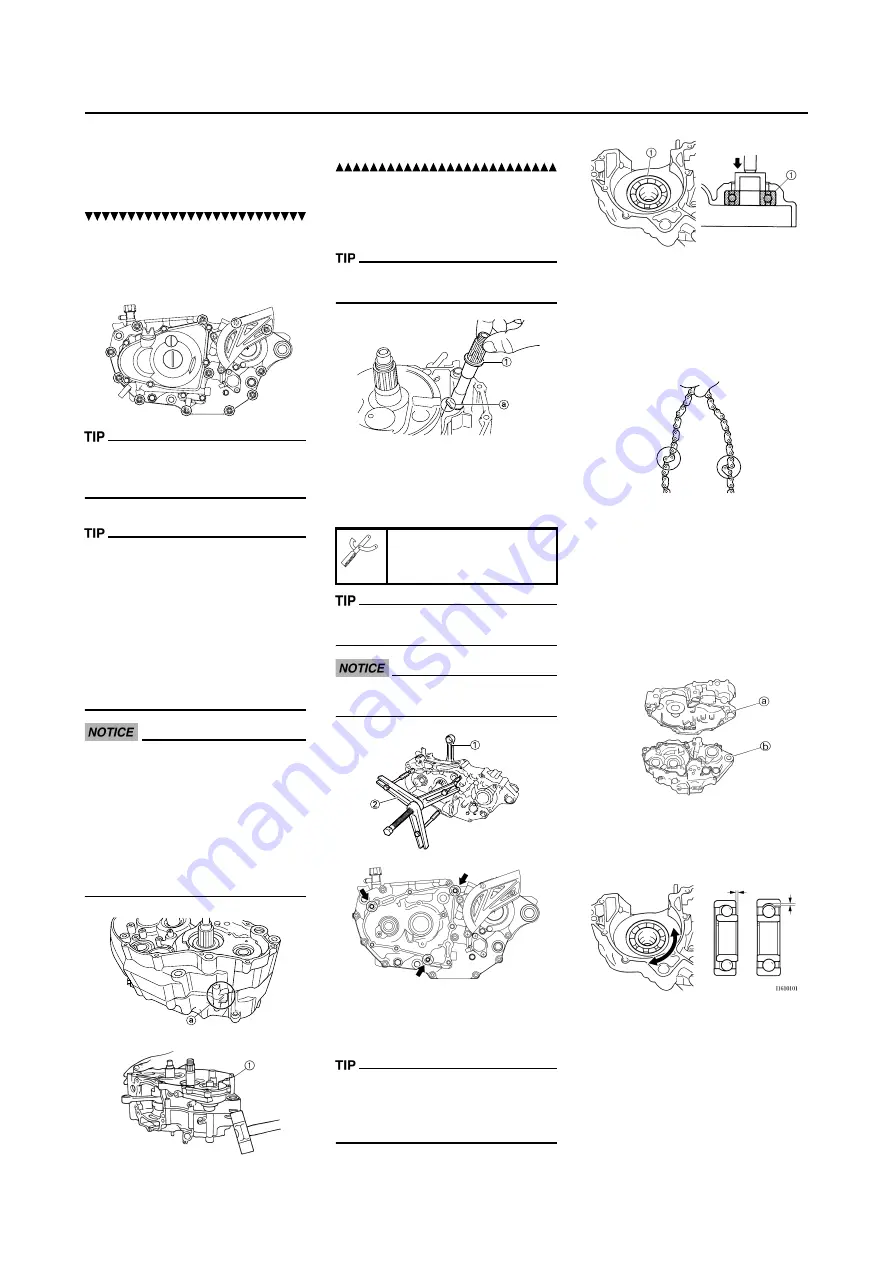

CHECKING THE CRANKCASE

1. Inspect:

• Contacting surface "a"

Scratches

→

Replace.

• Engine mounting boss "b", crank-

case

Cracks/damage

→

Replace.

2. Inspect:

• Bearing

Rotate inner race with a finger.

Rough spot/seizure

→

Replace.

3. Inspect:

• Oil seal

Damage

→

Replace.

Crankcase separating

tool:

YU-A9642/90890-04152

Summary of Contents for 2010 WR450FZ

Page 4: ......

Page 12: ...1 2 LOCATION OF IMPORTANT LABELS EUROPE ...

Page 13: ...1 3 LOCATION OF IMPORTANT LABELS AUS NZ ZA ...

Page 49: ...2 18 TIGHTENING TORQUES ...

Page 51: ...2 20 LUBRICATION DIAGRAMS 1 Intake camshaft 2 Exhaust camshaft A To main axle B From oil pump ...

Page 90: ...3 31 ELECTRICAL Charging method using a variable voltage charger ...

Page 91: ...3 32 ELECTRICAL Charging method using a constant voltage charger ...

Page 125: ...5 22 CYLINDER HEAD 3 Install Bolt cylinder head 1 Bolt cylinder head 10 Nm 1 0 m kg 7 2 ft lb ...

Page 144: ...5 41 OIL PUMP 15 Oil pump drive shaft 1 16 Rotor housing 1 Order Part name Q ty Remarks ...