TRANSMISSION

5-79

EBS30198

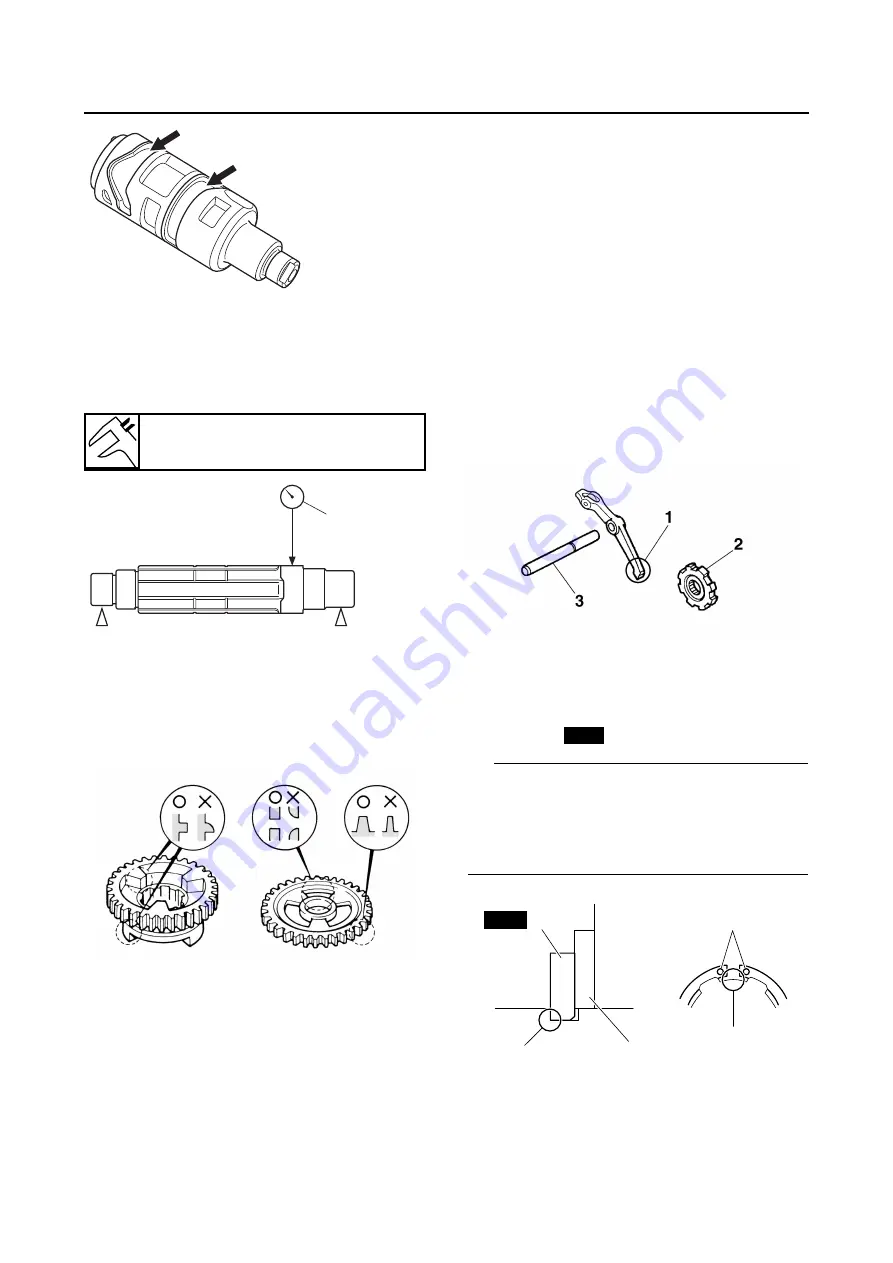

CHECKING THE TRANSMISSION

1. Measure:

• Drive axle runout

(with a centering device and dial gauge “1”)

Out of specification

→

Replace the drive axle.

2. Check:

• Transmission gears

Blue discoloration/pitting/wear

→

Replace

the defective gear(s).

• Transmission gear dogs

Cracks/damage/rounded edges

→

Replace

the defective gear(s).

3. Check:

• Transmission gear engagement

(each pinion gear to its respective wheel

gear)

Incorrect

→

Reassemble the transmission

axle assemblies.

4. Check:

• Transmission gear movement

Rough movement

→

Replace the defective

part(s).

EBS30199

CHECKING THE SECONDARY SHAFT

1. Check:

• Gear teeth

Blue discoloration/pitting/wear

→

Replace.

EBS30555

CHECKING THE STOPPER LEVER AND

STOPPER WHEEL

1. Check:

• Stopper lever pawl “1”

Bends/damage/wear

→

Replace the stopper

lever and stopper wheel as a set.

• Stopper wheel “2”

Damage/wear

→

Replace the stopper wheel

and stopper lever as a set.

• Stopper lever shaft “3”

Bends/damage/wear

→

Replace.

EBS30200

ASSEMBLING THE DRIVE AXLE

1. Install:

• Washer “1”

• Circlip “2”

TIP

• Be sure the circlip sharp-edged corner “a” is

positioned opposite side to the washer and

gear.

• Be sure the circlip ends “b” are positioned at

axle spline groove “c”.

EBS30201

ASSEMBLING THE SHIFT FORK

1. Install:

• Shift fork guide bar “1”

Drive axle runout limit

0.06 mm (0.0024 in)

1

New

a

1

c

b

2

New

Summary of Contents for 2016 Grizzly yf700gg

Page 6: ......

Page 8: ......

Page 11: ...IDENTIFICATION 1 2 ...

Page 37: ...ENGINE SPECIFICATIONS 2 6 Air induction system Solenoid resistance 18 22 Ω ...

Page 58: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 EBS30023 LUBRICATION DIAGRAMS 6 7 8 9 3 4 3 2 1 5 ...

Page 60: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 1 2 3 4 5 ...

Page 62: ...COOLING SYSTEM DIAGRAMS 2 31 EBS20021 COOLING SYSTEM DIAGRAMS 1 2 3 10 9 8 6 7 5 4 ...

Page 78: ...CABLE ROUTING 2 47 Front and rear brake hoses F 3 F 3 F 3 3 I G H 4 4 B C D 2 E D 2 A 1 ...

Page 80: ...CABLE ROUTING 2 49 ...

Page 83: ......

Page 119: ...PERIODIC MAINTENANCE 3 36 A Headlight left and right B Handle mounted light b a 1 A b a 1 B ...

Page 120: ...PERIODIC MAINTENANCE 3 37 ...

Page 197: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 74 7 9 8 9 7 3 5 4 5 3 6 2 10 10 1 ...

Page 198: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 75 ...

Page 203: ...ENGINE INSPECTION 5 2 Top cover Refer to GENERAL CHASSIS 2 on page 4 6 ...

Page 244: ...ELECTRIC STARTER 5 43 a b b 1 2 3 ...

Page 316: ...AIR INDUCTION SYSTEM 7 9 EBS20057 AIR INDUCTION SYSTEM 3 4 1 2 3 4 1 2 ...

Page 352: ...REAR CONSTANT VELOCITY SHAFT ASSEMBLIES FINAL DRIVE ASSEMBLY AND REAR DRIVE SHAFT 8 31 ...

Page 355: ......

Page 365: ...ELECTRIC STARTING SYSTEM 9 10 ...

Page 369: ...CHARGING SYSTEM 9 14 ...

Page 417: ...FUEL PUMP SYSTEM 9 62 ...

Page 434: ...ELECTRICAL COMPONENTS 9 79 1 2 3 5 7 8 9 10 11 12 13 14 15 16 17 18 19 4 6 ...

Page 454: ...ELECTRICAL COMPONENTS 9 99 ...

Page 468: ......

Page 469: ......

Page 470: ......