FUEL INJECTION SYSTEM

9-41

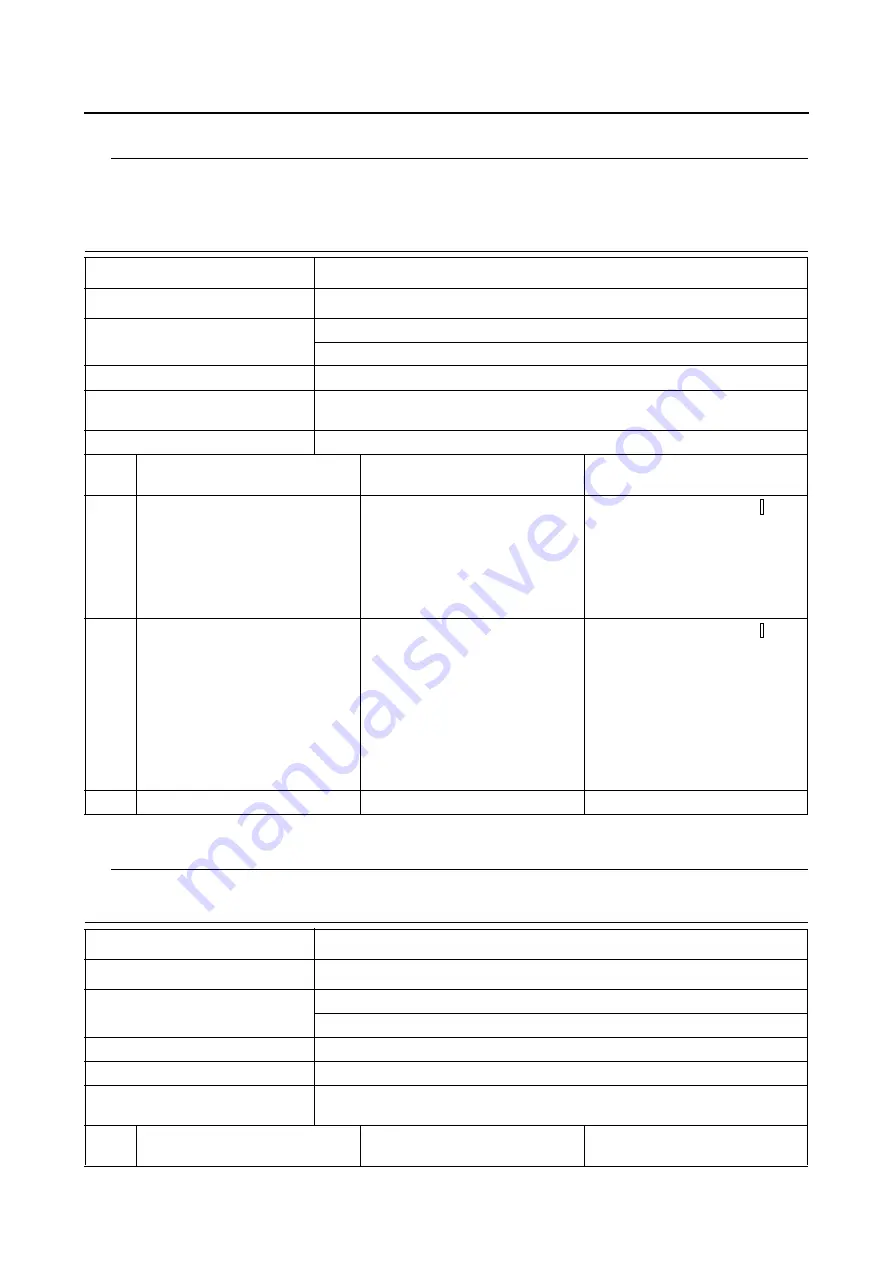

Fault code No. 16

TIP

• If fault code numbers “15” and “16” are both indicated, take the actions specified for fault code number

“15” first.

• If fault code numbers “16” and “37” are both indicated, take the actions specified for fault code number

“16” first.

Fault code No. 21

TIP

If fault code numbers “21” and “37” are both indicated, take the actions specified for fault code number

“21” first.

Fault code No.

16

Item

Throttle position sensor: stuck throttle position sensor is detected.

Fail-safe system

Able to start engine

Able to drive vehicle

Diagnostic code No.

01

Indicated

Throttle position sensor signal

• 14–20 (fully closed position)

Procedure

Check with throttle valve fully closed.

Item

Probable cause of malfunc-

tion and check

Maintenance job

Confirmation of service com-

pletion

1

Installed condition of throttle po-

sition sensor.

Check for looseness or pinch-

ing.

Improperly installed sensor

→

Reinstall or adjust the sensor.

Refer to “ADJUSTING THE

THROTTLE POSITION SEN-

SOR” on page 7-7.

Turn the main switch to “

”

(on), then push the throttle le-

ver.

Fault code number is not dis-

played

→

Service is finished.

Fault code number is displayed

→

Go to item 2.

2

Defective throttle position sen-

sor.

Check throttle position sensor

signal.

Execute the diagnostic mode.

(Code No. 01)

When the throttle valve is fully

closed:

A value of 14–20 is indicated.

An indicated value is out of the

specified range

→

Replace the

throttle position sensor.

Turn the main switch to “

”

(on), then operate the throttle.

Fault code number is not dis-

played

→

Service is finished.

Fault code number is displayed

→

Go to item 3.

3

Malfunction in ECU.

Replace the ECU.

Fault code No.

21

Item

Coolant temperature sensor: open or short circuit detected.

Fail-safe system

Able to start engine

Able to drive vehicle

Diagnostic code No.

06

Indicated

Displays the coolant temperature.

Procedure

Compare the actually measured coolant temperature with the indicated

value.

Item

Probable cause of malfunc-

tion and check

Maintenance job

Confirmation of service com-

pletion

Summary of Contents for 2016 Grizzly yf700gg

Page 6: ......

Page 8: ......

Page 11: ...IDENTIFICATION 1 2 ...

Page 37: ...ENGINE SPECIFICATIONS 2 6 Air induction system Solenoid resistance 18 22 Ω ...

Page 58: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 EBS30023 LUBRICATION DIAGRAMS 6 7 8 9 3 4 3 2 1 5 ...

Page 60: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 1 2 3 4 5 ...

Page 62: ...COOLING SYSTEM DIAGRAMS 2 31 EBS20021 COOLING SYSTEM DIAGRAMS 1 2 3 10 9 8 6 7 5 4 ...

Page 78: ...CABLE ROUTING 2 47 Front and rear brake hoses F 3 F 3 F 3 3 I G H 4 4 B C D 2 E D 2 A 1 ...

Page 80: ...CABLE ROUTING 2 49 ...

Page 83: ......

Page 119: ...PERIODIC MAINTENANCE 3 36 A Headlight left and right B Handle mounted light b a 1 A b a 1 B ...

Page 120: ...PERIODIC MAINTENANCE 3 37 ...

Page 197: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 74 7 9 8 9 7 3 5 4 5 3 6 2 10 10 1 ...

Page 198: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 75 ...

Page 203: ...ENGINE INSPECTION 5 2 Top cover Refer to GENERAL CHASSIS 2 on page 4 6 ...

Page 244: ...ELECTRIC STARTER 5 43 a b b 1 2 3 ...

Page 316: ...AIR INDUCTION SYSTEM 7 9 EBS20057 AIR INDUCTION SYSTEM 3 4 1 2 3 4 1 2 ...

Page 352: ...REAR CONSTANT VELOCITY SHAFT ASSEMBLIES FINAL DRIVE ASSEMBLY AND REAR DRIVE SHAFT 8 31 ...

Page 355: ......

Page 365: ...ELECTRIC STARTING SYSTEM 9 10 ...

Page 369: ...CHARGING SYSTEM 9 14 ...

Page 417: ...FUEL PUMP SYSTEM 9 62 ...

Page 434: ...ELECTRICAL COMPONENTS 9 79 1 2 3 5 7 8 9 10 11 12 13 14 15 16 17 18 19 4 6 ...

Page 454: ...ELECTRICAL COMPONENTS 9 99 ...

Page 468: ......

Page 469: ......

Page 470: ......