PERIODIC MAINTENANCE

3-1

EBS20023

PERIODIC MAINTENANCE

EBS30024

INTRODUCTION

This chapter includes all information necessary to perform recommended checks and adjustments. If

followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a lon-

ger service life and reduce the need for costly overhaul work. This information applies to vehicles al-

ready in service as well as to new vehicles that are being prepared for sale. All service technicians

should be familiar with this entire chapter.

EBS30025

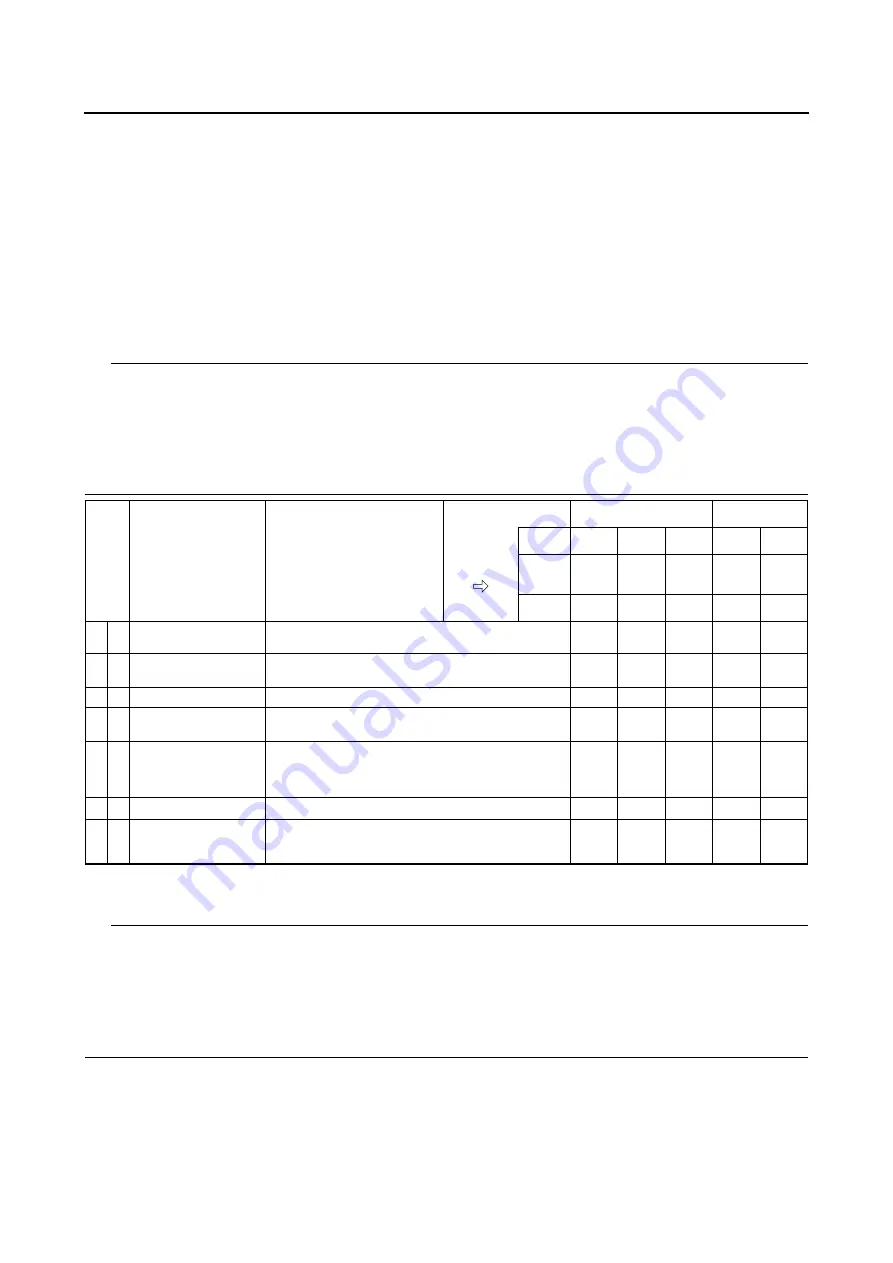

PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL SYSTEM

TIP

• For vehicles not equipped with an odometer or an hour meter, follow the month maintenance intervals.

• For vehicles equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance

intervals. However, keep in mind that if the vehicle isn’t used for a long period of time, the month main-

tenance intervals should be followed.

• Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools,

data and technical skills.

EBS30026

GENERAL MAINTENANCE AND LUBRICATION CHART

TIP

• For vehicles not equipped with an odometer or an hour meter, follow the month maintenance intervals.

• For vehicles equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance

intervals. However, keep in mind that if the vehicle isn’t used for a long period of time, the month main-

tenance intervals should be followed.

• Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools,

data and technical skills.

NO.

ITEM

CHECK OR MAINTENANCE

JOB

INITIAL

EVERY

Whichever

comes first

month

1

3

6

6

12

km (mi)

320

(200)

1300

(800)

2500

(1600)

2500

(1600)

5000

(3200)

hours

20

80

160

160

320

1

*

Fuel line

• Check fuel hoses for cracks or other damage, and re-

place if necessary.

√

√

√

2

Spark plug

• Check condition and clean, regap, or replace if nec-

essary.

√

√

√

√

√

3

*

Valves

• Check valve clearance and adjust if necessary.

√

√

√

√

4

*

Crankcase breather

system

• Check breather hose for cracks or other damage, and

replace if necessary.

√

√

√

5

*

Exhaust system

• Check for leakage and replace gasket(s) if neces-

sary.

• Check for looseness and tighten all screw clamps

and joints if necessary.

√

√

√

6

Spark arrester

• Clean.

√

√

√

7

*

Air induction system

• Check the air cut-off valve, reed valve, and hose for

damage.

• Replace any damaged parts if necessary.

√

√

√

√

√

Summary of Contents for 2016 Grizzly yf700gg

Page 6: ......

Page 8: ......

Page 11: ...IDENTIFICATION 1 2 ...

Page 37: ...ENGINE SPECIFICATIONS 2 6 Air induction system Solenoid resistance 18 22 Ω ...

Page 58: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 EBS30023 LUBRICATION DIAGRAMS 6 7 8 9 3 4 3 2 1 5 ...

Page 60: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 1 2 3 4 5 ...

Page 62: ...COOLING SYSTEM DIAGRAMS 2 31 EBS20021 COOLING SYSTEM DIAGRAMS 1 2 3 10 9 8 6 7 5 4 ...

Page 78: ...CABLE ROUTING 2 47 Front and rear brake hoses F 3 F 3 F 3 3 I G H 4 4 B C D 2 E D 2 A 1 ...

Page 80: ...CABLE ROUTING 2 49 ...

Page 83: ......

Page 119: ...PERIODIC MAINTENANCE 3 36 A Headlight left and right B Handle mounted light b a 1 A b a 1 B ...

Page 120: ...PERIODIC MAINTENANCE 3 37 ...

Page 197: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 74 7 9 8 9 7 3 5 4 5 3 6 2 10 10 1 ...

Page 198: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 75 ...

Page 203: ...ENGINE INSPECTION 5 2 Top cover Refer to GENERAL CHASSIS 2 on page 4 6 ...

Page 244: ...ELECTRIC STARTER 5 43 a b b 1 2 3 ...

Page 316: ...AIR INDUCTION SYSTEM 7 9 EBS20057 AIR INDUCTION SYSTEM 3 4 1 2 3 4 1 2 ...

Page 352: ...REAR CONSTANT VELOCITY SHAFT ASSEMBLIES FINAL DRIVE ASSEMBLY AND REAR DRIVE SHAFT 8 31 ...

Page 355: ......

Page 365: ...ELECTRIC STARTING SYSTEM 9 10 ...

Page 369: ...CHARGING SYSTEM 9 14 ...

Page 417: ...FUEL PUMP SYSTEM 9 62 ...

Page 434: ...ELECTRICAL COMPONENTS 9 79 1 2 3 5 7 8 9 10 11 12 13 14 15 16 17 18 19 4 6 ...

Page 454: ...ELECTRICAL COMPONENTS 9 99 ...

Page 468: ......

Page 469: ......

Page 470: ......