4 - 93

ENG

MIDDLE GEAR

●

To find shim thickness “B” use the following

formula:

Middle driven pinion gear shim thick-

ness:

“B” =

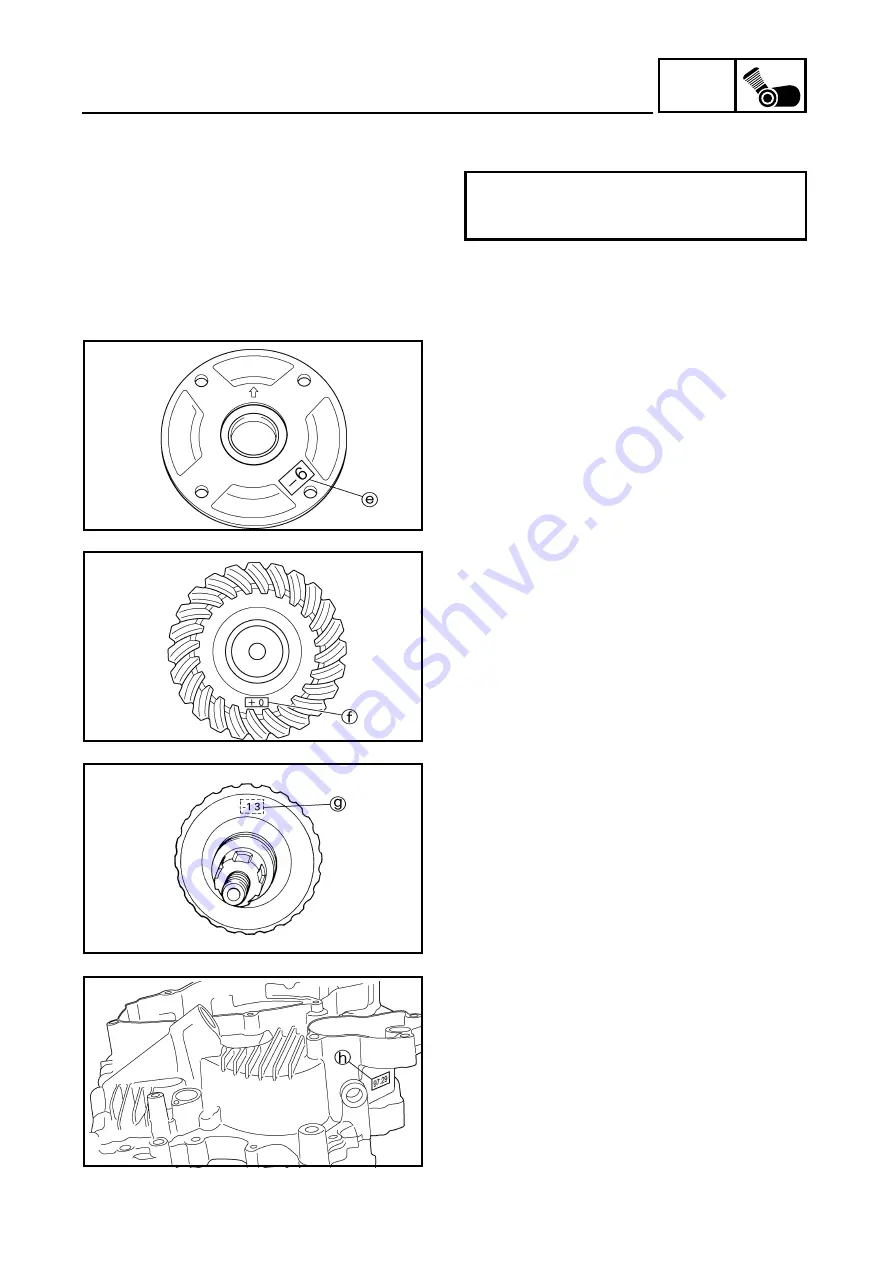

e

–

f

+

g

–

h

+

i

– 0.05

Where:

e

= a numeral (usually a decimal number)

on the bearing housing is either added

to or subtracted from “76”.

f

= a numeral (usually a decimal number)

on the middle driven pinion gear is

either added to or subtracted from “60”.

g

= a numeral (usually a decimal number)

on the middle driven pinion gear is

either added to or subtracted from

“80.5”.

h

= a numeral (usually a decimal number)

on the left crankcase specifies a thick-

ness of “97.29”.

i

= a numeral (usually a decimal number)

on the right crankcase specifies a

thickness of “1.67”.

Example:

1) If the bearing housing is marked “–06”,

......

e

is 75.94.

2) If the driven pinion gear is marked “+0”,

......

f

is 60.00.

3) If the driven pinion gear is marked “–13”,

......

g

is 80.37.

4) If the crankcase (left) is marked “97.29”,

......

h

is 97.29.

5) If the crankcase (right) is marked “1.67”,

......

i

is 1.67.

6) Therefore, the shim thickness is 0.64 mm.

B = 75.94 – 60.00 + 80.37 – 97.29 + 1.67

– 0.05 = 0.64

Summary of Contents for 5KM2-AE1

Page 1: ...YFM660F P 5KM2 AE1 SERVICEMANUAL 2002 ...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 29: ......

Page 30: ...SPEC 2 ...

Page 32: ...SPEC ...

Page 43: ...2 11 SPEC MAINTENANCE SPECIFICATIONS Item Standard Cylinder head tightening sequence ...

Page 73: ...CHK ADJ 3 ...

Page 142: ...ENG 4 ...

Page 146: ...ENG ...

Page 244: ......

Page 245: ...COOL 5 ...

Page 247: ...COOL ...

Page 259: ......

Page 260: ...CARB 6 ...

Page 262: ...CARB ...

Page 270: ......

Page 271: ...DRIV 7 ...

Page 273: ...DRIV ...

Page 306: ...CHAS 8 ...

Page 363: ...ELEC 9 ...

Page 365: ... ELEC 2WD 4WD SELECTING SYSTEM 9 51 CIRCUIT DIAGRAM 9 51 TROUBLESHOOTING 9 52 ...

Page 421: ......

Page 422: ...TRBL SHTG 10 ...

Page 424: ...TRBL SHTG ...