Elements of Sound

L Series

Non-scalloped, 90˚ X-type bracing. 8 non-

scalloped braces deliver tone that is thick

and well focused.

FG/FS Series

Non-scallop, X-type bracing design. Deliv-

ers deep lows full of presence that are

unique to the Yamaha sound, and a clear

upper end. Response is clear and tight.

APX Series

Non-scalloped X-type bracing design. Deliv-

ers a well-balanced sound when played acous-

tically. Oval soundhole offers thicker middle

highs that are unique to the APX sound.

CPX Series

Non-scalloped, X-type bracing positioned

closer to the sound hole enhances low-end.

Overall rich sound with good response and

powerful lows.

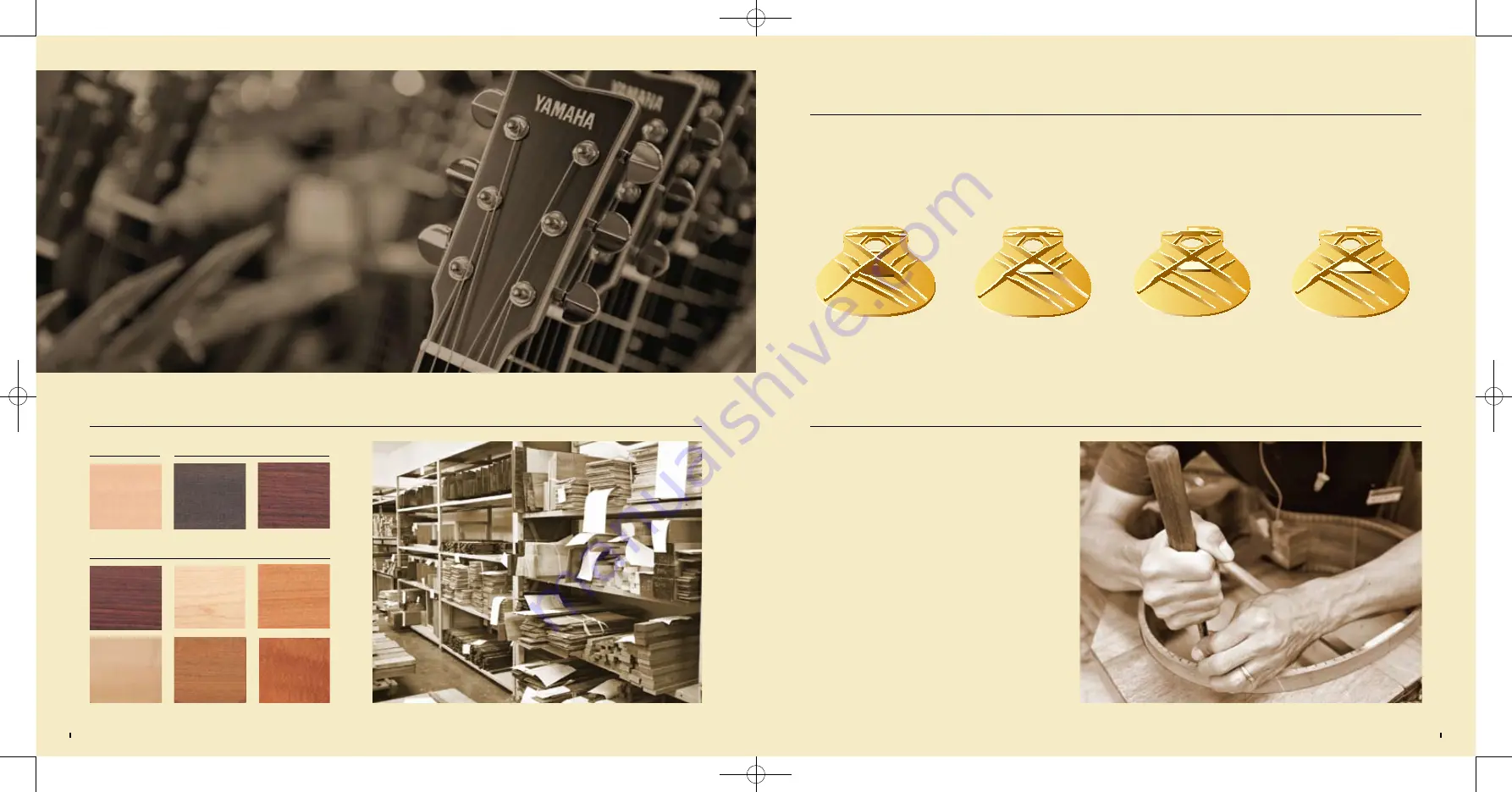

Back & Sides

Woods

Craftmanship

Quilted Mahogany

Mahogany

Sycamore

Walnut

Indian Rosewood

Maple

Top

Finger Board & Bridge

Spruce

Indian Rosewood

Ebony

Yamaha’s true strengths as a guitar maker are not apparent in product

brochures or specifications, but they are clearly reflected in the sound,

playability, dependability, and overall quality of every guitar that bears the

Yamaha name. “The Yamaha Advantage” includes information that will

hopefully provide a clearer picture of the prodigious resources and

effort that give artists who choose Yamaha a significant musical advantage.

Bracing – thin strips of wood glued to the underside of the guitar’s top

– is, in addition to the type and cut of the wood used, one of the most

important elements influencing the guitar’s volume and tone.

Bracing applied to the back and sides also has an effect on sonic per-

formance. The bracing configuration used can mean the difference

between the success or failure of an instrument, and ideally will comple-

Yamaha Acoustic Guitars

Essential Knowledge and

The Yamaha Difference

Even with the advanced manufacturing technology

available today it simply isn’t possible to entirely au-

tomate the production of first class acoustic guitars.

The complexity of the task in addition to the need for

constant awareness of the materials being used and the

ability to minutely adjust for variations is beyond the

scope of available technology.

Machines do play a vital role, but there is no substitute

for the skill and sensitivity of experienced craftsmen

at many stages during the production of fine musical

instruments.

In addition to factories in Japan, Yamaha operates gui-

tar factories in China and Indonesia that are run in the

same way. From raw materials to production processes,

Yamaha maintains the same demanding standards at all

factories to ensure that every instrument that bears the

Yamaha logo delivers the fit and finish plus the sound

and playability that we intend and our customers have

come to expect.

ment and enhance the qualities of the woods used and the instrument’s

overall design. Too much bracing or braces that are too heavy will result

in a dead sounding guitar. At the other extreme – too little bracing or

braces that are too light – the guitar might sound unfocused and boomy,

and the top may be prone to distortion and breakage.

Yamaha Essential Knowledge

43

Yamaha Essential Knowledge

44