6D45F11

5-44

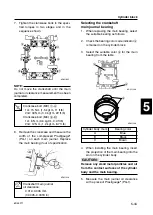

9

8

7

6

5

4

3

2

1

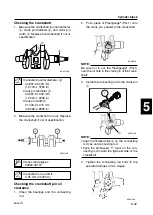

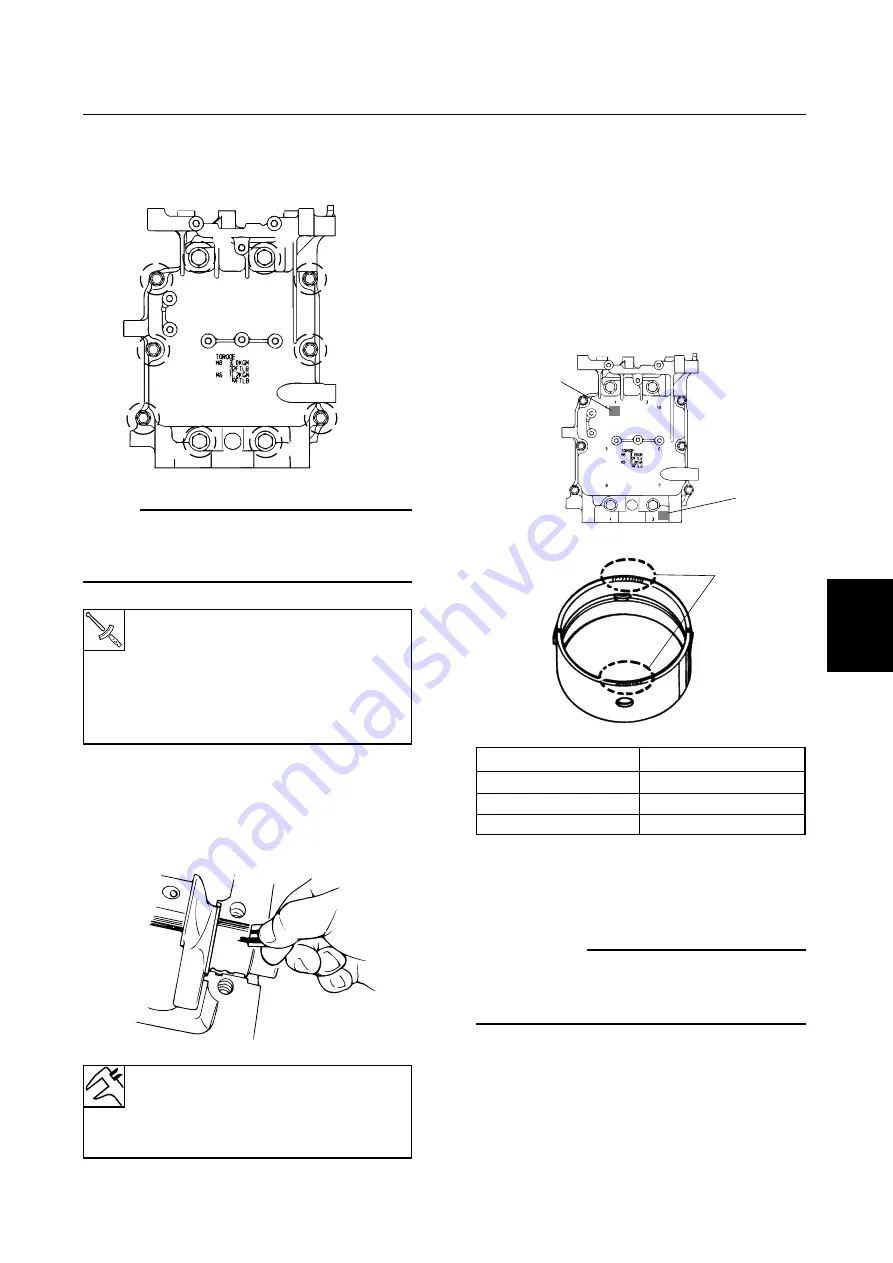

7.

Tighten the crankcase bolts to the speci-

fied torques in two stages and in the

sequence shown.

NOTE:

Do not move the crankshaft until the main

journal oil clearance measurement has been

completed.

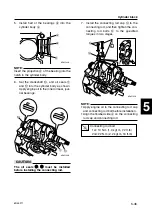

8.

Remove the crankcase and measure the

width of the compressed Plastigauge

®

(PG-1) on each main journal. Replace

the main bearing if out of specification.

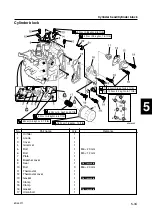

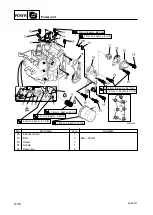

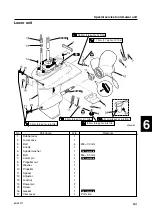

Cylinder block

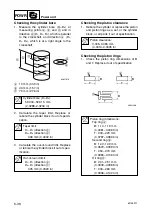

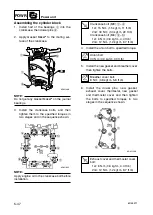

Selecting the crankshaft

main journal bearing

1.

When replacing the main bearing, select

the suitable bearing as follows.

2.

Check the bearing color code indicator

a

is marked on the cylinder block.

3.

Select the suitable color

b

for the main

bearing from the table.

4.

When installing the main bearing, insert

the projection of the main bearing into the

slot on the cylinder body.

c

C

Remove any small metal particles and oil

from the contact surfaces of the cylinder

body and the main bearing.

5.

Measure the main journal oil clearance

with a piece of Plastigauge

®

(PG-1).

Crankcase bolt (M8):

1

–

4

1st: 15 N·m (1.5 kgf·m, 11 ft·lb)

2nd: 30 N·m (3.0 kgf·m, 22 ft·lb)

Crankcase bolt (M6):

5

–

0

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 12 N·m (1.2 kgf·m, 8.7 ft·lb)

6D451330

a

a

6D451380

b

6D451390

Crankshaft main journal

oil clearance:

0.012–0.045 mm

(0.0005–0.0018 in)

Cylinder body mark

Bearing color

A

Blue

B

Black

C

Brown

1

9

5

8

4

3

7

6

10

2

6D451035

0

9

8

7

6

5

4

3

2

1

6D45F11-05 03.10.9 20:44 Page 47