6D45F11

9

8

7

6

5

4

3

2

1

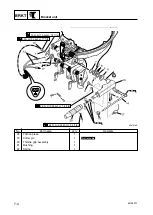

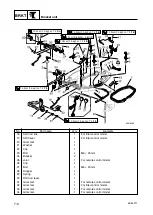

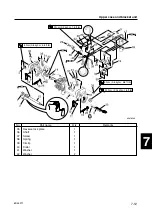

BRKT

Bracket unit

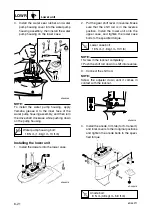

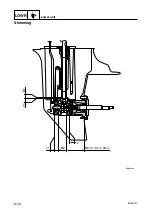

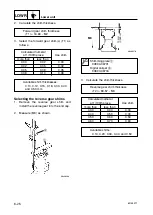

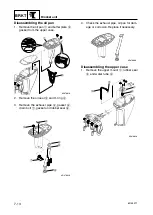

Disassembling the oil pan........................................................................7-13

Disassembling the upper case ................................................................7-13

Checking the upper case.........................................................................7-14

Assembling the upper case .....................................................................7-14

6D45F11-07 03.10.9 20:46 Page 1