3-13

CHK

ADJ

6D45F11

Periodic checks and adjustments

Checking the propeller

1.

Check the propeller blades and splines

for cracks, damage, or wear. Replace if

necessary.

General

Checking the anode

1.

Check the anode for scales, grease, and

oil. Clean if necessary.

c

C

Do not oil, grease, or paint the anode, oth-

erwise it will be ineffective.

2.

Replace the anode if excessively eroded.

6D430335

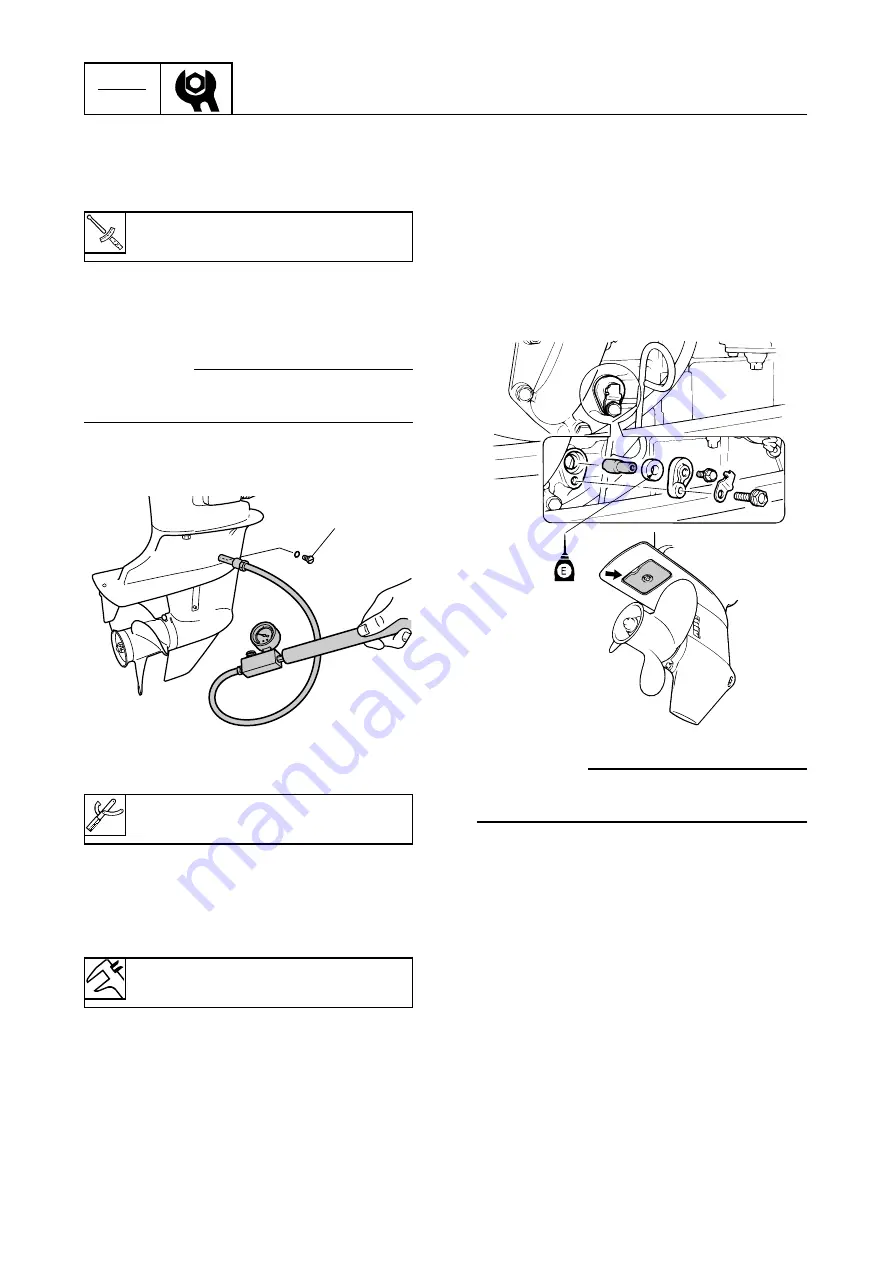

5. Install the check screw, quickly install the

drain screw, then tighten them to the spec-

ified torque.

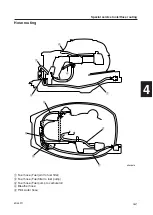

Checking the lower unit

for air leakage

c

C

Do not over pressurize the lower unit, oth-

erwise the oil seals may be damaged.

1.

Remove the check screw

1

, then install

the special service tool.

2.

Apply the specified pressure to check

whether the lower unit can hold it for at

least 10 seconds.

3.

If pressure drops below specification,

check the drive shaft, propeller shaft oil

seals, shift rod, and drain screw for dam-

age.

Leakage tester: 90890-06840

Check and drain screw:

9 N·m (0.9 kgf·m, 6.6 ft·lb)

Lower unit holding pressure:

100 kPa (1.0 kgf/cm

2

, 14 psi)

6D430300

1

6D45F11-03 03.10.9 20:43 Page 14