0-4

0

How to use this manual

Manual format

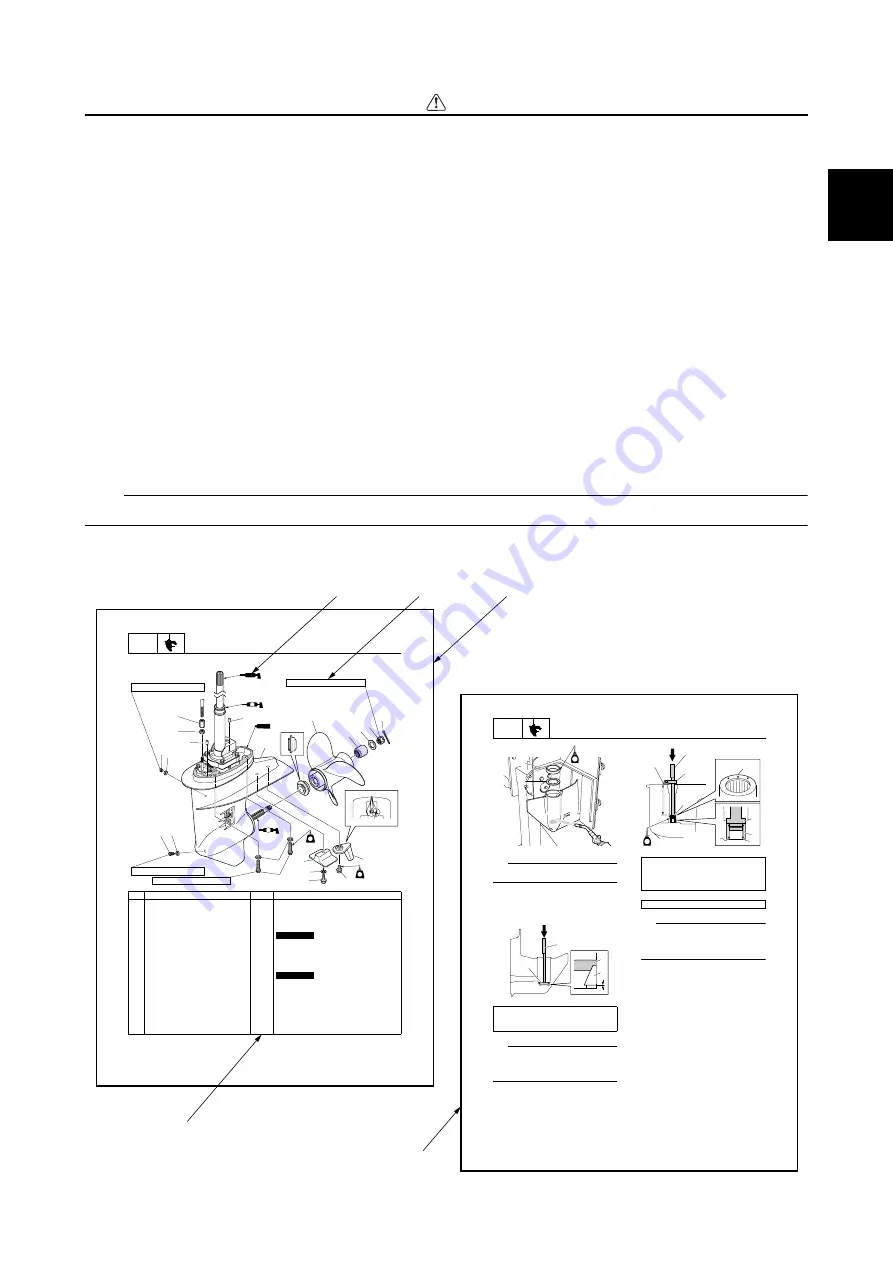

The format of this manual has been designed to make service procedures clear and easy to under-

stand. Use the following information as a guide for effective and quality service.

• Parts are shown and detailed in an exploded diagram and are listed in the component list (see

1

in the following figure for an example page).

• The component list consists of part names and quantities, as well as bolt and screw dimensions

(see

2

in the following figure).

• Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant and

the lubrication points (see

3

in the following figure).

• Tightening torque specifications are provided in the exploded diagrams (see

4

in the following fig-

ure), and in the related detailed instructions. Some torque specifications are listed in stages as

torque figures or angles in degrees.

• Separate procedures and illustrations are used to explain the details of removal, checking, and

installation where necessary (see

5

in the following figure for an example page).

TIP:

For troubleshooting procedures, see Chapter 4, “Troubleshooting.”

LOWR

Lower unit

8-1

Lower unit

No.

Part name

Q’ty

Remarks

1

t

u

n

g

n

i

t

s

u

j

d

A

1

1

t

u

n

k

c

o

L

2

2

l

e

w

o

D

3

1

w

e

r

c

s

k

c

e

h

C

4

2

t

e

k

s

a

G

5

Not reusable

1

w

e

r

c

s

n

i

a

r

D

6

4

r

e

h

s

a

W

7

0

1

M

4

t

l

o

B

8

×

35 mm

1

e

d

o

n

A

9

1

r

e

h

s

a

w

l

a

i

c

e

p

S

0

1

Not reusable

6

M

1

t

l

o

B

1

1

×

35 mm

6

M

1

t

l

o

B

2

1

×

18 mm

1

b

a

t

m

i

r

T

3

1

1

t

i

n

u

r

e

w

o

L

4

1

1

r

e

c

a

p

S

5

1

1

r

e

ll

e

p

o

r

P

6

1

1

r

a

ll

o

C

7

1

3

1

2

3

6

5

5

4

20

19

18

17

15

16

14

13

12

11

10

9

8

7

518

M

A

D

LT

572

LT

LT

572

LT

1901

9 N

·

m (0.9 kgf

·

m, 6.6 ft

·

Ib)

9 N

·

m (0.9 kgf

·

m, 6.6 ft

·

Ib)

34 N

·

m (3.4 kgf

·

m, 25.1 ft

·

Ib)

37 N

·

m (3.7 kgf

·

m, 27.3 ft

·

Ib)

LOWR

Lower unit

8-17

TIP:

Do not reuse a shim if deformed or

scratched.

3.

While holding the special service tool

3

,

strike the tool to check that the taper

roller bearing outer race is installed prop-

erly.

TIP:

If a high-pitched metallic sound is produced

when the special service tool is struck, the

taper roller bearing outer race

2

is installed

properly.

4.

Install a new needle bearing

5

to the

specified depth

a

.

TIP:

• Face the identification mark

b

on the nee-

dle bearing toward the water pump side.

• Install the stopper

c

onto the driver rod

6

at the specified depth

a

.

5.

Heat the installation area of the taper

roller bearing outer race in the lower

case using a gas torch, and then install

the sleeve

9

, the original pinion shims

0

, and a new taper roller bearing outer

race

A

.

NOTICE: When heating the

lower case, heat the entire installation

area evenly. Otherwise, the paint on

the lower case could be burned.

Driver rod LL

3

: 90890-06605

Bearing outer race attachment

4

:

90890-06625

1

2

G

3

2

1

3

Driver rod SL

6

: 90890-06602

Bearing depth plate

7

: 90890-06603

Needle bearing attachment

8

:

90890-06615

Depth

a

: 185.0–186.0 mm (7.28–7.32 in)

a

c

5

7

6

G

b

4

7

2

5

3

4

1