E

CYLINDER HEAD AND PUSH ROD

POWR

4

2

2

1

3

SERVICE POINTS

NOTE:

Cylinder head maintenance is possible

with the power unit mounted.

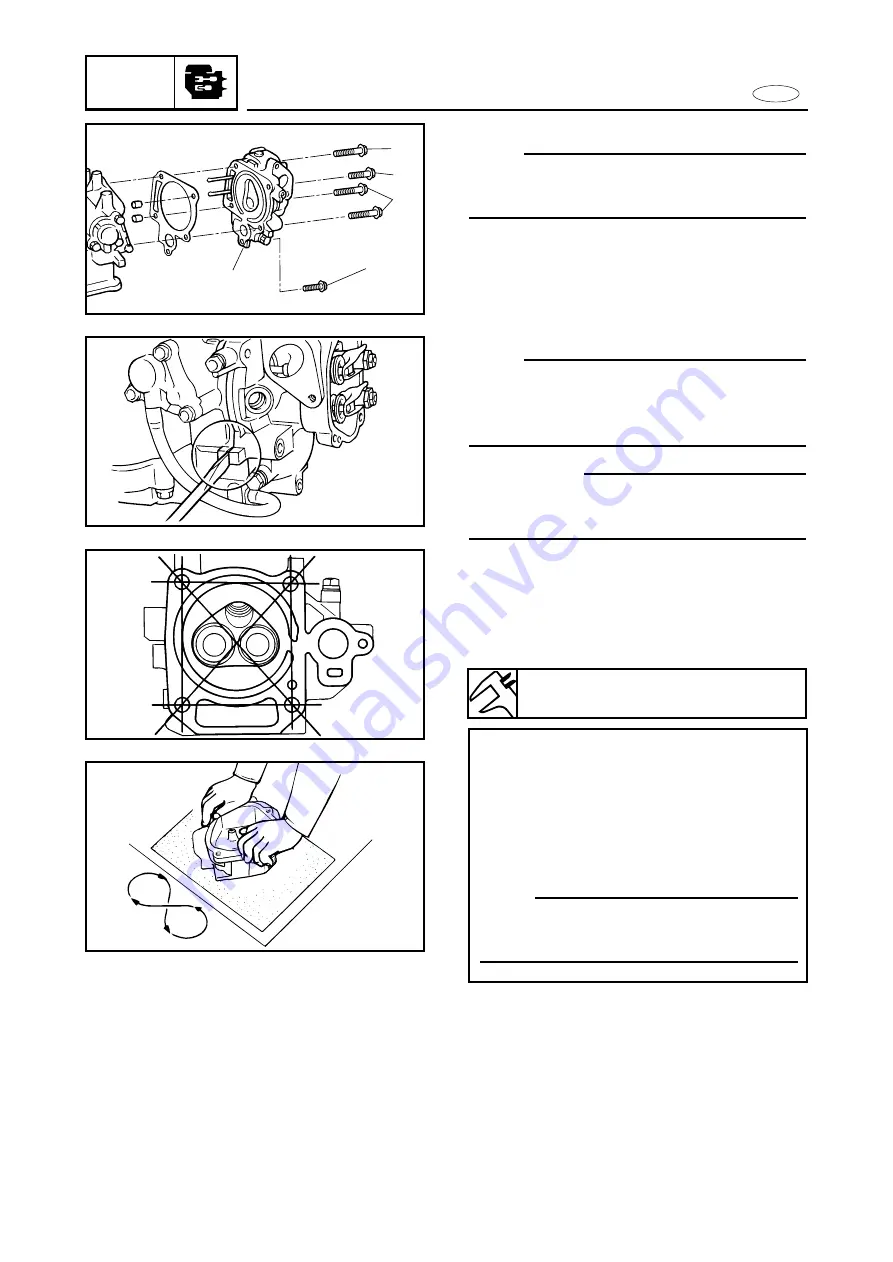

Cylinder head removal

1. Remove:

9

Bolt

1

(M6 x 45 mm)

9

Bolt

2

(M8 x 60 mm x 3)

9

Bolt

3

(M8 x 40 mm x 1)

9

Cylinder head

4

NOTE:

Insert a flat-head screwdriver between the

tabs on both side of the cylinder and cylin-

der head and pry open the two parts.

c

C

Do not scratch the interface of cylinder

and cylinder head.

5-13

Warpage limit:

0.1 mm (0.004 in)

Resurfacing steps:

8

Place a 400 ~ 600 grit wet sandpaper

on the surface plate.

8

Resurface the cylinder head using a

figure-eight sanding pattern.

To ensure an even surface, rotate the

cylinder head several times.

NOTE:

To ensure an even surface, rotate the

cylinder head several times.

Cylinder head inspection

1. Measure:

9

Cylinder head warpage

Out of specification

®

Resurface or

replace the cylinder head.