E

CRANKCASE, CRANKSHAFT AND CAMSHAFT

POWR

D

D

1

2

D

D and D

1

2

D and D

3

4

D and D

5

6

70 mm (2.8 in)

40 mm (1.6 in)

10 mm (0.4 in)

1

2

a

d

SERVICE POINTS

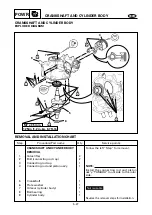

Crankcase removal

1. Remove:

9

Crankcase

1

9

Cylinder body

2

NOTE:

9

Position the crankcase up side down.

9

Insert a flat-head screwdriver between the

tabs on both side of the crankcase and

cylinder body and pry open the two parts.

c

C

Do not scratch the interface of the

crankcase and cylinder.

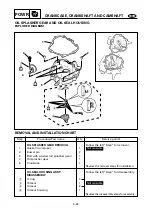

Piston inspection

1. Measure:

9

Piston diameter

Out of specification

®

Replace the

piston.

5-30

Standard

Wear limit

Cylinder

59.00 ~ 59.02 mm

bore “D” (2.323 ~ 2.324 in)

—

Taper

0.08 mm

limit “T”

—

(0.003 in)

Out of

0.05 mm

round limit

—

(0.002 in)

D=Maximum Dia. (D

1

~D

6

)

T=(maximum D

1

or D

2

) ~ (minimum D

5

or

D

6

)

Distance

Piston diameter

d

a

10 mm

58.950 ~ 58.965 mm

Standard

(0.39 in)

(2.3209 ~ 2.3215 in)

Cylinder inspection

1. Measure:

9

Cylinder bore

Out of specification

®

Rebore or

replace the cylinder.

NOTE:

Measure the cylinder bore in parallel and

at right angle to the crankshaft. Then, aver-

age the measurements.