BRKT

Bracket unit

7-43

6C13G11

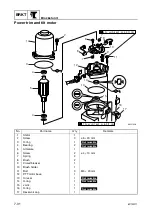

Checking the tilt cylinder and trim

cylinder

1.

Check the inner walls of the trim cylinder

and tilt cylinder for scratches. Replace if

necessary.

2.

Check the outer surface of the tilt piston

and free piston for scratches. Replace if

necessary.

3.

Check the tilt ram for bends or excessive

corrosion. Polish with 400- to 600-grit

sandpaper if there is light rust or replace

if necessary.

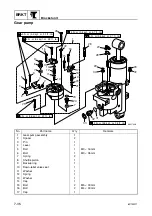

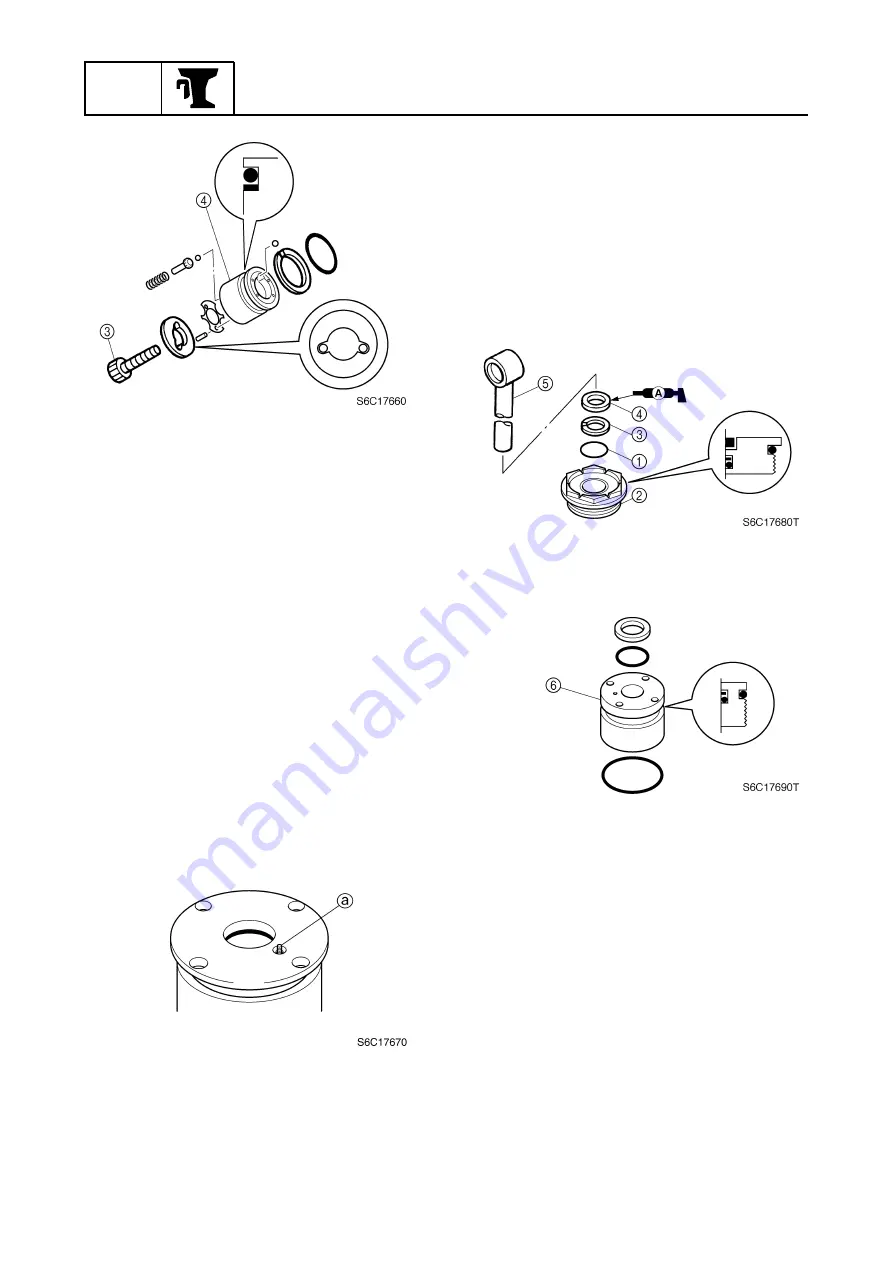

Checking the valves

1.

Check the operation of the check valve

a

of the tilt cylinder end screw and

check the valve for dirt or residue. Clean

if necessary.

2.

Check the operation of the absorber

valve and check the valve for dirt or resi-

due. Clean if necessary.

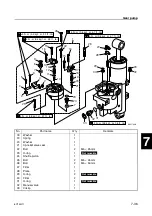

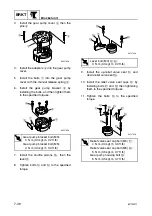

Assembling the tilt cylinder

1.

Install new O-ring

1

into the trim cylinder

end screw

2

.

2.

Install a new dust seal

3

and new oil

seal

4

into the trim cylinder end screw

2

.

3.

Install the tilt ram

5

into the trim cylinder

end screw

2

.

4.

Install the backup ring and new O-rings

into the tilt cylinder end screw

6

.

5.

Install the tilt cylinder end screw onto the

tilt ram.

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...