6C13G11

7-46

1

2

3

4

5

6

7

8

9

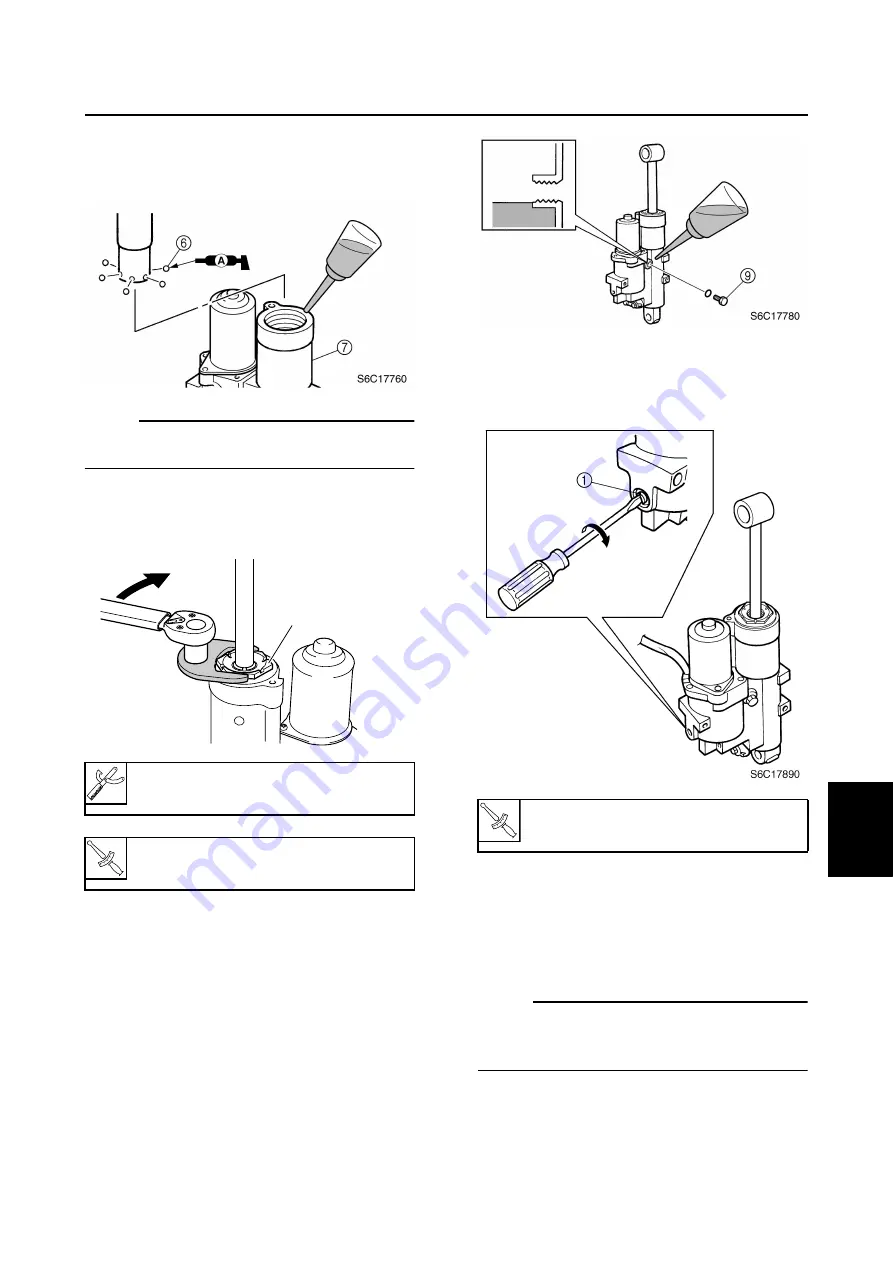

7.

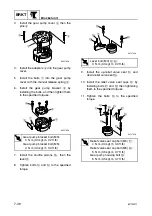

Install the balls

6

into the tilt cylinder,

and then insert the tilt cylinder into the

trim cylinder

7

.

NOTE:

Apply grease to the balls to prevent them

from falling off.

8.

Install the trim cylinder end screw

8

, and

then tighten it to the specified torque.

9.

Fully extend the tilt rod, and then add suf-

ficient fluid of the recommended type to

the correct level.

10. Install the reservoir cap

9

.

Bleeding the power trim and tilt unit

1.

Tighten the manual valve

1

by turning it

clockwise.

2.

Place the power trim and tilt unit in an

upright position.

3.

Remove the reservoir cap, and then

check the fluid level in the reservoir.

NOTE:

If the fluid is at the correct level, the fluid

should overflow out of the filler hole when the

reservoir cap is removed.

4.

If necessary, add sufficient fluid of the

recommended type until it overflows out

of the filler hole.

Cylinder-end screw wrench:

90890-06588

T

R

.

.

Trim cylinder end screw

8

:

110 N·m (11.0 kgf·m, 81.1 ft·lb)

S6C17770

8

T

R

.

.

Manual valve

1

:

2 N·m (0.2 kgf·m, 1.5 ft·lb)

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...