2-16

E

EMU00161

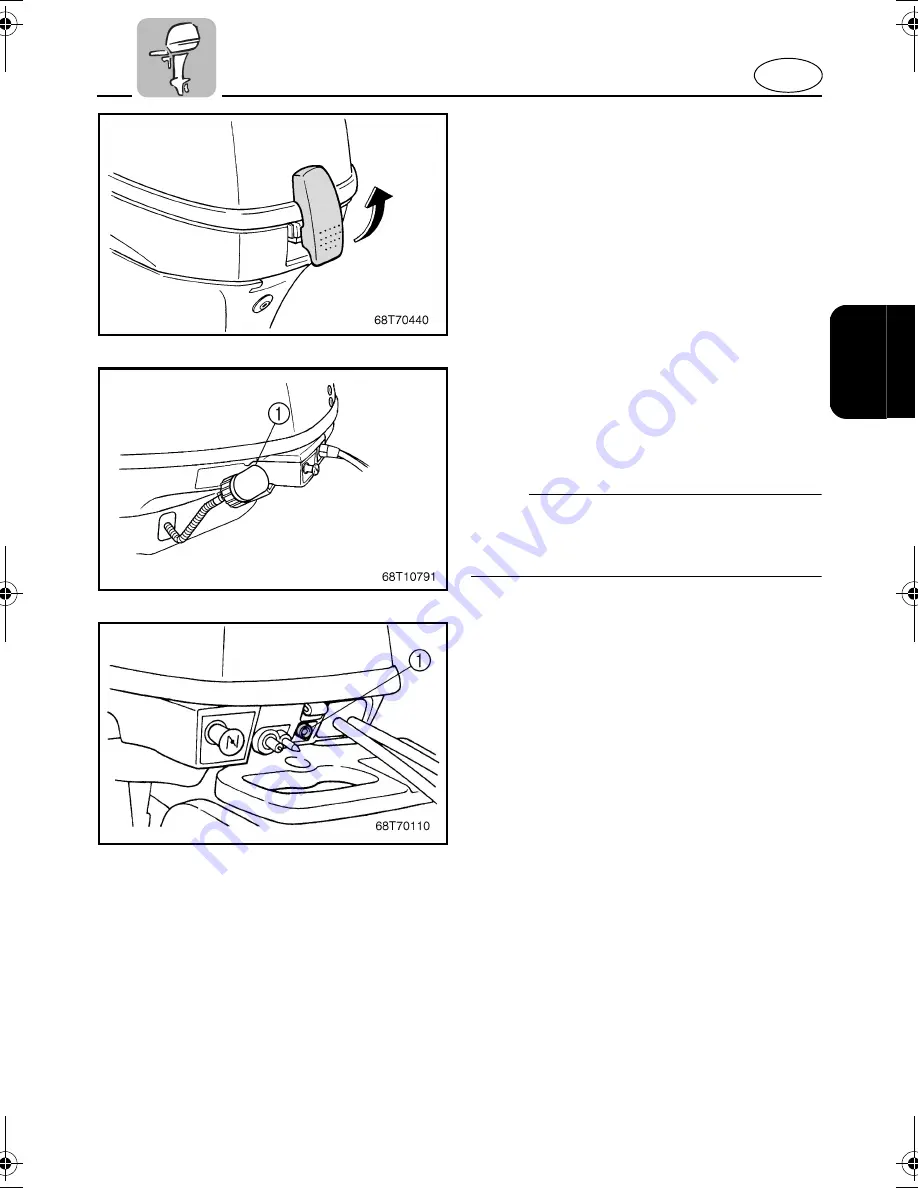

TOP COWLING LOCK LEVER

To remove the engine top cowling, pull up

the lock lever. Then lift off the cowling. When

replacing the cowling, check to be sure it fits

properly in the rubber seal. Then lock the

cowling again by moving the lever down-

ward.

EMU01701

FLUSHING DEVICE

This device

1

is used to clean the cooling

water passages of the motor using a garden

hose and tap water.

NOTE:

@

Refer to “CLEANING COOLING-WATER

PASSAGES” in Chapter 4 for instructions on

usage.

@

EMU01128

WARNING INDICATOR(S)

If the engine develops a condition monitored

by the warning system, an indicator will

come on. Refer to the “WARNING SYSTEM”

section for details.

1

Warning indicator(s)

U68T15.book Page 16 Thursday, March 20, 2003 11:28 AM

Summary of Contents for F6C

Page 1: ...F6C ...

Page 2: ......

Page 11: ...1 6 E EMU00014 IMPORTANT LABELS WARNING LABELS 1 2 CAUTION LABELS 3 ...

Page 22: ...1 17 E MEMO ...

Page 72: ...3 31 E 2 Slightly tilt up the engine using the power tilt switch ...

Page 74: ...3 33 E MEMO ...

Page 87: ...4 12 E EMU00366 GREASING Yamaha marine grease Water resistant grease ...

Page 119: ...E 6 EMU00450 Chapter 6 INDEX INDEX 6 1 ...

Page 127: ......

Page 129: ...PLACE POSTAGE HERE ATTN WARRANTY DEPARTMENT ...