Maintenance

75

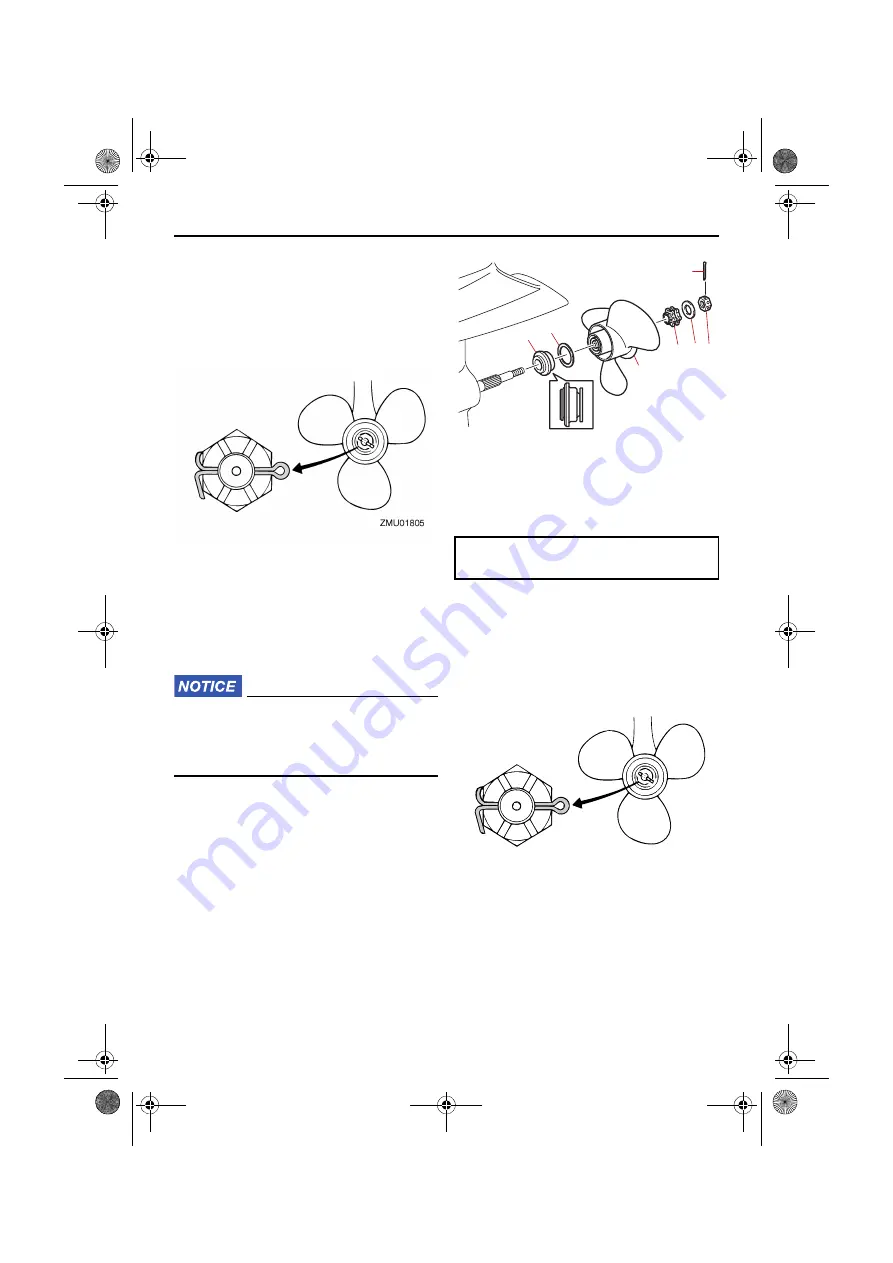

(4) Align the propeller nut with the propeller

shaft hole. Insert a new cotter pin in the

hole and bend the cotter pin ends.

NOTICE:

Do not reuse the cotter pin.

Otherwise, the propeller can come off

during operation.

[ECM01892]

TIP:

If the propeller nut does not align with the

propeller shaft hole after tightening to the

specified torque, tighten the nut further to

align it with the hole.

EMU46512

Dual thrust models

ECM00502

Make sure to use a new cotter pin and

bend the ends over securely. Otherwise,

the propeller could come off during oper-

ation and be lost.

(1) Apply Yamaha marine grease or a corro-

sion resistant grease to the propeller

shaft.

(2) Install the thrust washer, washer, and

propeller on the propeller shaft.

NOTICE:

Make sure to install the thrust washer

before installing the propeller. Other-

wise, the lower case and propeller

boss could be damaged.

[ECM01882]

(3) Install the spacer and the washer. Tight-

en the propeller nut to the specified

torque.

(4) Align the propeller nut with the propeller

shaft hole. Insert a new cotter pin in the

hole and bend the cotter pin ends.

NOTICE:

Do not reuse the cotter pin.

Otherwise, the propeller can come off

during operation.

[ECM01892]

TIP:

If the propeller nut does not align with the

propeller shaft hole after tightening to the

specified torque, tighten the nut further to

align it with the hole.

1. Cotter pin

2. Propeller nut

3. Washer

4. Spacer

5. Propeller

6. Thrust washer

Propeller nut tightening torque:

21 N·m (2.1 kgf·m, 15 lb·ft)

6 3

2

3

4

5

1

ZMU0206

3

U6FW76E0.book Page 75 Tuesday, November 23, 2021 7:37 AM