1 - 15

GEN

INFO

FEATURES

O

2

sensor

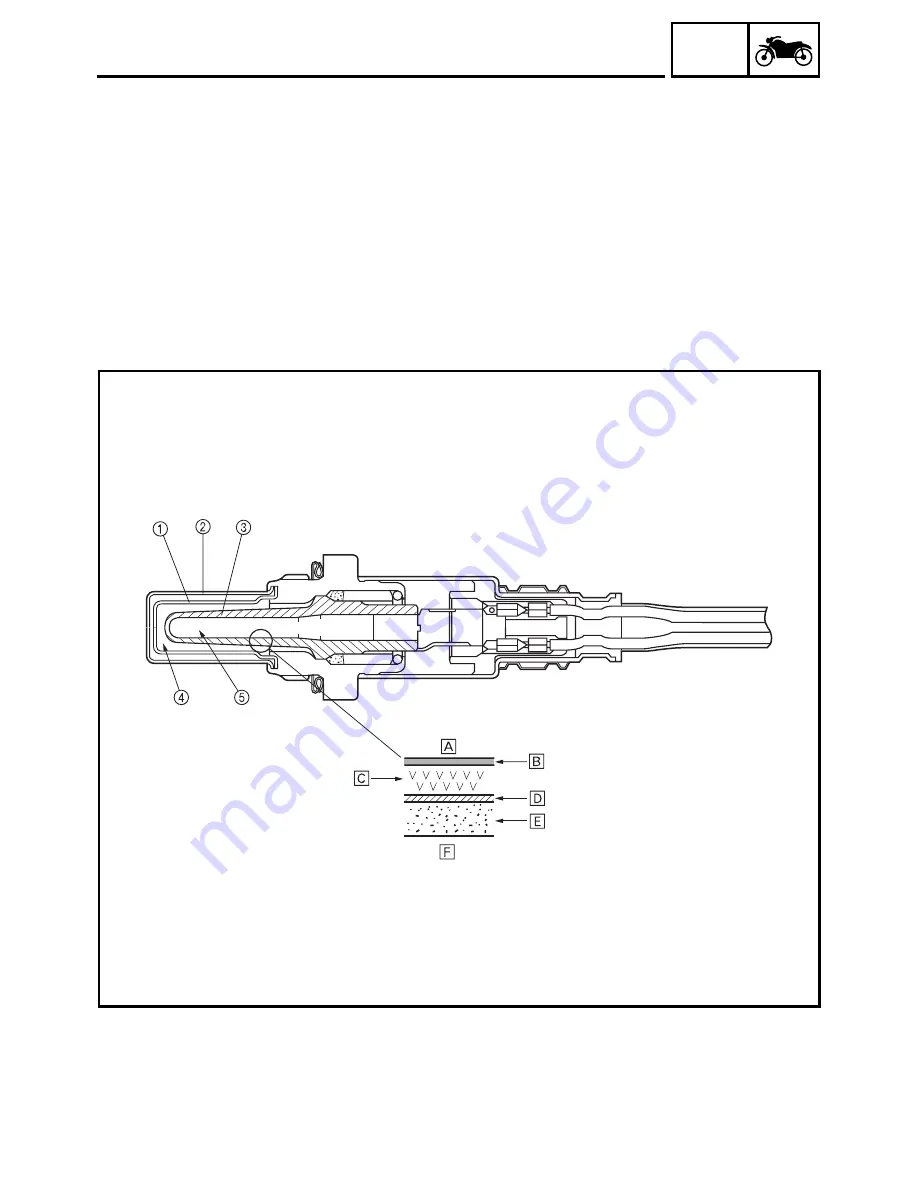

The O

2

sensor has been adopted to enable the catalyst to function at a high degree of efficiency by

maintaining the air-fuel mixture near the stoichiometric ratio (14.7:1). This sensor, which is a zirco-

nia type, utilizes the oxygen ion conductivity of the solid electrolyte for detecting the oxygen concen-

tration levels. In actual operation, a zirconia tube made of solid electrolyte is exposed in the exhaust

gas, so that the exterior of the zirconia tube is in contact with the exhaust gas and the interior is in

contact with the atmosphere whose oxygen concentration level is known. When a difference in the

oxygen concentration level is created between the outside and the inside of the zirconia tube, the

oxygen ion passes through the zirconia element and generates an electromotive force. The electro-

motive force increases when the oxygen concentration level is low (rich air-fuel ratio) and the elec-

tromotive force decreases when the oxygen concentration level is high (lean air-fuel ratio). As

electromotive force is generated in accordance with the concentration of the exhaust gas, the result-

ant voltage is input into the ECU in order to correct the duration of the injection of fuel.

1

Inner cover

2

Outer cover

3

Zirconia tube

4

Exhaust gas

5

Atmosphere

È

Atmosphere

É

Inner electrode

Ê

Zirconia element

Ë

Outer electrode

Ì

Porous ceramic layer

Í

Exhaust gas

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...