1 - 27

GEN

INFO

FEATURES

Functions of components

Catalyst

Because the conditions in which NOx is generated are directly opposed to those of CO and HC,

there is a limit to the extent to which the concentration levels of these harmful elements can be

reduced in the combustion stage. Hence, the function of the catalyst is to clean the exhaust gas at a

high degree of efficiency by removing CO, HC, and NOx in the exhaust stage.

This model has adopted a monolith type metallic catalyst with a honeycomb construction, which

achieves a low exhaust resistance through the large surface area of the catalyst body (with a high

level of cleaning efficiency).

Catalytic substances consisting of precious metals such as platinum and rhodium are adhered to

the wall surface of these honeycomb cells, which are enclosed in the exhaust pipe. As the exhaust

gas comes in contact with these catalytic substances, the chemical reactions of oxidation and

reduction advance in order to clean the exhaust gas.

• The CO and HC oxidize with the oxidation function of platinum, and are converted into harmless

carbon dioxide (CO

2

) and water (H

2

O), resulting in cleaner exhaust gases.

• The NOx is reduced by the reduction function of rhodium, which converts NOx into harmless nitro-

gen (N

2

) and oxygen (O

2

), resulting in cleaner exhaust gases.

To clean the exhaust gases at a high rate of efficiency through the maximization of these catalytic

capacities, it is necessary to maintain and control the mixture in the vicinity of the stoichiometric air-

fuel ratio of (14.7:1) at all times. As a means of maintaining the stoichiometric ratio, this system has

adopted an O

2

feedback compensation method that uses an O

2

sensor, which will be described in

the next section.

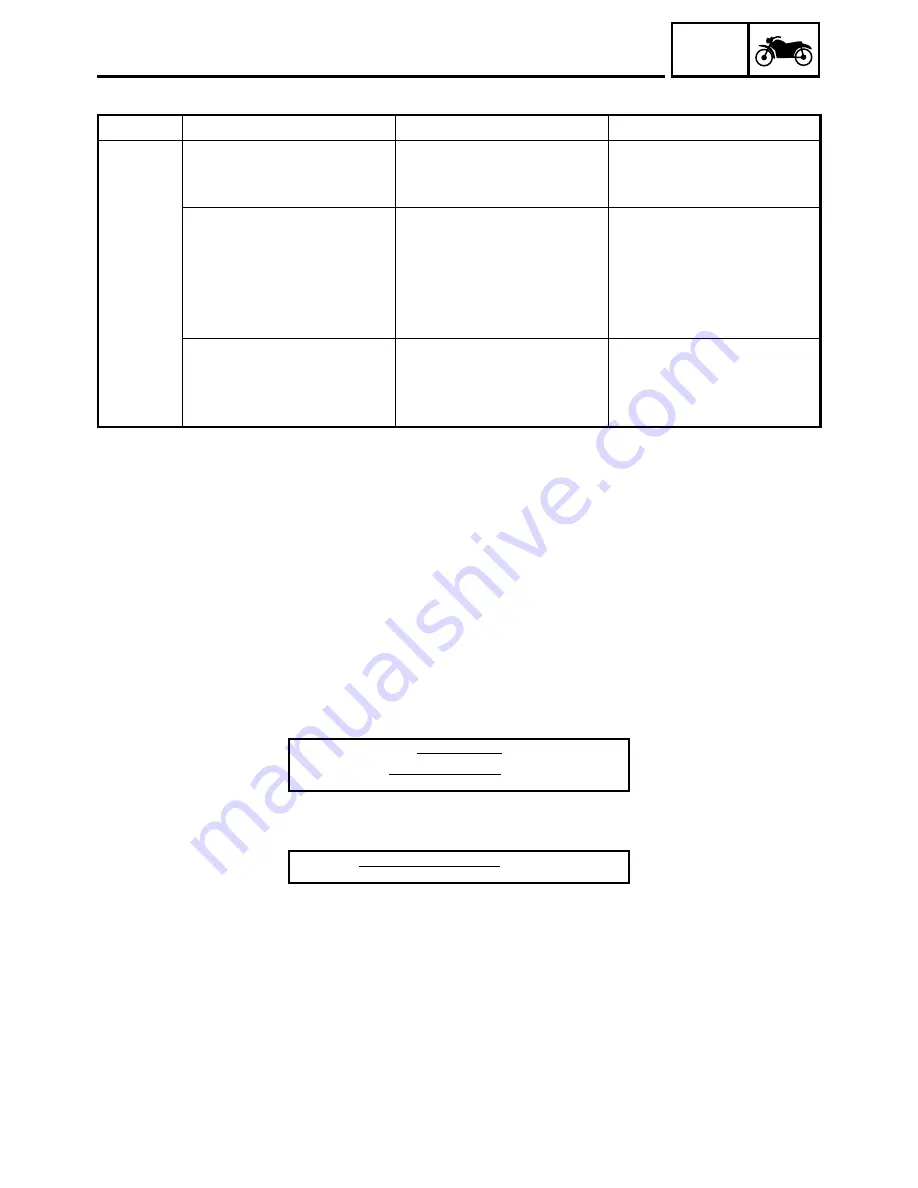

Equipment

Functions

Main components

Three-way catalytic

converter system

Catalyzer (honeycomb

type)

Simultaneously reduces

CO, HC, and NOx emis-

sions.

• Catalytic converter

• Catalyst case

Air-fuel compensation

equipment

Reduces CO, HC, and NOx

emissions. The catalyst pri-

marily cleans the exhaust

gases in order to ensure

the stoichiometric air-fuel

ratio.

• O

2

sensor

• ECU

Fuel cut-off equipment

Reduces CO and HC emis-

sions, improves fuel econ-

omy, and cuts off fuel

during deceleration.

• Throttle position sensor

• ECU

CO + 1/2 O

2

CO

2

HC + O

2

CO

2

+ H

2

O

NOx

N

2

+ O

2

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...