8 - 42

–

+

ELEC

SIGNALING SYSTEM

YES

NO

YES

NO

EAS00800

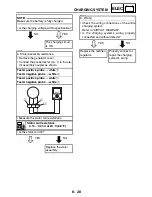

4. The neutral indicator light fails to come on.

YES

NO

YES

NO

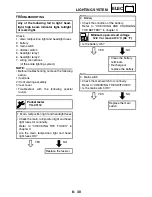

• Set the main switch to “ON”.

• Set the turn signal switch to “

” or “

”.

• Measure the voltage (12 V) on brown/white

1

at the turn signal relay coupler.

• Is the voltage within specification?

The turn signal relay

is faulty and must be

replaced.

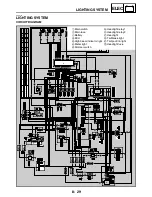

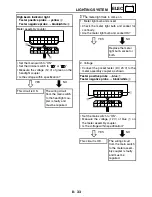

5. Voltage

• Connect the pocket tester (DC 20 V) to the

front turn signal light connectors (wire har-

ness side), tail light assembly coupler (wire

harness side) or meter assembly coupler as

shown.

È

Front turn signal light

É

Rear turn signal light

Ê

Turn signal indicator light

Left turn signal light

Tester positive probe

→

chocolate

1

Tester negative probe

→

ground

Right turn signal light

Tester positive probe

→

dark green

2

Tester negative probe

→

ground

Ch

Dg

Ch

Dg

Ch

B

Y L

Dg Y L

B

1

2

R

/

W G

/

W Y

/

L

Lg

Y

Ch

Dg

L

R

/

G B

/

W

Br

/

R

W

• Set the main switch to “ON”.

• Set the turn signal switch to “

” or “

”.

• Measure the voltage (12 V) of the chocolate

1

or dark green

2

.

• Is the voltage within specification?

This circuit is OK.

The wiring circuit

from the turn signal

switch to the front

turn signal light con-

nectors (wire harness

side), tail light

assembly coupler

(wire harness side)

or meter assembly

coupler is faulty and

must be repaired.

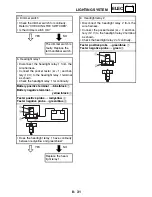

1. Neutral indicator light bulb and socket

• Check the neutral indicator light bulb and

socket for continuity.

• Are the neutral indicator light bulb and

socket OK?

Replace the neutral

indicator light bulb,

socket or both.

2. Neutral switch

• Check the neutral switch for continuity.

Refer to “CHECKING THE SWITCHES”.

• Is the neutral switch OK?

Replace the neutral

switch.

È

É

Ê

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...