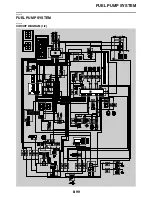

FUEL INJECTION SYSTEM

8-95

Fault code No.

43

Symptom The ECU is unable to monitor the battery voltage (an open

or short circuit in the line to the ECU).

Diagnostic code No.

d:09

Fuel system voltage

Order Item/components and probable

cause

Check or maintenance job

Reinstatement

method

1

Connections

• Relay unit coupler

• Wire harness ECU coupler

• Front cowling wire harness coupler

• Check the coupler for any pins

that may be pulled out.

• Check the locking condition of

the coupler.

• If there is a malfunction, repair it

and connect the coupler se-

curely.

Starting the en-

gine and oper-

ating it at idle.

2

Open or short circuit in the wire har-

ness and/or front cowling wire har-

ness.

• Repair or replace if there is an

open or short circuit.

• Between relay unit coupler and

ECU coupler.

(blue/yellow–blue/yellow)

(red/blue–red/blue)

• Between relay unit coupler and

engine stop switch coupler.

(red/black–red/black)

3

Malfunction or open circuit in fuel

pump relay.

• Execute the diagnostic mode.

(Code No.d:09)

• Replace if defective.

• If there is no malfunction with

the fuel pump relay, replace the

ECU.

Fault code No.

44

Symptom An error is detected while reading or writing on EEPROM

(CO adjustment value).

Diagnostic code No.

d:60

EEPROM fault cylinder No.

Order Item/components and probable

cause

Check or maintenance job

Reinstatement

method

1

Malfunction in ECU.

• Set the faulty cylinder’s exhaust

gas volume.

1. Execute the diagnostic mode

(Code No.d:60) to check the

faulty cylinder number. (If

multiple cylinders are defec-

tive, the numbers of the

faulty cylinders are displayed

alternately at 2-second inter-

vals.)

• Replace ECU if it does not re-

cover from the malfunction.

Turning the

main switch to

“ON”.

(Readjust the

exhaust gas

volume after it

is reinstated.)

Summary of Contents for FJR13AY 2009

Page 1: ...2009 SERVICE MANUAL FJR13AY C FJR13AEY C LIT 11616 22 73 3P6 28197 12 ...

Page 6: ......

Page 8: ......

Page 80: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 31 EAS20410 LUBRICATION DIAGRAMS 5 6 7 1 2 3 4 ...

Page 82: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 33 1 3 2 ...

Page 83: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 34 1 Main axle 2 Drive axle 3 Oil delivery pipe 1 ...

Page 84: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 35 6 5 4 3 2 1 ...

Page 86: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 37 1 2 3 4 5 6 7 8 9 ...

Page 88: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 39 4 5 3 2 1 9 8 6 7 ...

Page 92: ...COOLING SYSTEM DIAGRAMS 2 43 A A 7 1 2 3 4 5 5 7 8 6 8 9 10 11 12 ...

Page 98: ...CABLE ROUTING FJR13A 2 49 2 3 4 5 6 7 8 9 11 10 12 13 14 15 16 A B C D E F 1 1 ...

Page 100: ...CABLE ROUTING FJR13A 2 51 1 2 3 4 5 6 7 8 A B C D E 9 10 11 12 13 ...

Page 108: ...CABLE ROUTING FJR13A 2 59 1 2 3 4 A B B C D E ...

Page 110: ...CABLE ROUTING FJR13A 2 61 A 1 A A B P O C D E F G H I J K L M N 2 3 4 5 6 7 8 9 10 A 11 ...

Page 118: ...CABLE ROUTING FJR13AE 2 69 2 3 4 5 6 7 8 9 11 12 13 14 15 16 17 A B C E D F 1 1 H 10 18 G ...

Page 120: ...CABLE ROUTING FJR13AE 2 71 1 2 3 4 5 6 7 8 A B C D E 9 10 11 12 13 ...

Page 128: ...CABLE ROUTING FJR13AE 2 79 1 4 2 5 6 A B C D D E 3 F G ...

Page 130: ...CABLE ROUTING FJR13AE 2 81 A 1 A A B P O C D E F G H I J K L M N 2 3 4 5 6 7 8 9 10 A 11 ...

Page 134: ...CABLE ROUTING FJR13AE 2 85 ...

Page 137: ......

Page 196: ...GENERAL CHASSIS 4 11 b a 1 2 ...

Page 302: ...SHAFT DRIVE 4 117 ...

Page 326: ...CAMSHAFTS 5 21 ...

Page 424: ...CONNECTING RODS AND PISTONS 5 119 ...

Page 462: ...WATER PUMP 6 15 ...

Page 473: ...THROTTLE BODIES 7 10 ...

Page 474: ...AIR INDUCTION SYSTEM 7 11 EAS27040 AIR INDUCTION SYSTEM 1 2 3 4 5 1 1 1 1 2 2 5 2 3 3 4 7 8 6 ...

Page 483: ......

Page 495: ...IGNITION SYSTEM 8 12 ...

Page 511: ...ELECTRIC STARTING SYSTEM 8 28 ...

Page 513: ...CHARGING SYSTEM 8 30 2 Rectifier regulator 3 AC magneto 8 Main fuse 10 Battery ...

Page 515: ...CHARGING SYSTEM 8 32 ...

Page 539: ...COOLING SYSTEM 8 56 ...

Page 587: ...FUEL PUMP SYSTEM 8 104 ...

Page 599: ...ACCESSORY BOX SYSTEM 8 116 ...

Page 609: ...ABS ANTI LOCK BRAKE SYSTEM 8 126 ...

Page 698: ...ELECTRICAL COMPONENTS 8 215 FJR13A 5 1 3 2 17 8 10 11 12 13 14 15 16 7 6 4 9 ...

Page 700: ...ELECTRICAL COMPONENTS 8 217 FJR13AE 13 16 18 17 2 3 4 5 6 7 8 1 9 10 11 12 15 14 19 ...

Page 702: ...ELECTRICAL COMPONENTS 8 219 FJR13AE 1 19 3 2 5 7 9 8 12 13 14 15 16 11 10 18 17 6 4 ...

Page 730: ...ELECTRICAL COMPONENTS 8 247 ...

Page 739: ......

Page 740: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...