Safety Instructions

S-20

4.6.2 Automatic operation

Check the following points when operating the robot in AUTO mode. Observe the instructions below in cases

where an error occurs during automatic operation. Automatic operation described here includes all operations

in AUTO mode.

1.

Checkpoints before starting automatic operation

Check the following points before starting automatic operation.

w

DANGER

• Check that no one is within the safety enclosure.

• Check the safety enclosure is securely installed with interlocks functional.

w

WARNING

• Check that the programming box / handy terminal and tools are in their specified locations.

• Check that the signal tower lamps or other alarm displays installed for the system are not lit or flashing,

indicating no error is occurring on the robot and peripheral devices.

2.

During automatic operation and when errors occur

After automatic operation starts, check the operation status and the signal tower to ensure that the robot is in automatic

operation.

w

DANGER

Never enter the safety enclosure during automatic operation.

w

WARNING

If an error occurs in the robot or peripheral equipment, observe the following procedure before entering the

safety enclosure.

1) Press the emergency stop button to set the robot to emergency stop.

2) Place a sign on the start switch, indicating that the robot is being inspected in order to keep other persons from

restarting the robot.

4.6.3 Precautions during operation

1.

When the robot is damaged or an abnormal condition occurs

w

WARNING

• If unusual odors, noise or smoke occur during operation, immediately turn off power to prevent possible

electrical shock, fire or breakdown. Stop using the robot and contact your distributor.

• If any of the following damage or abnormal conditions occurs the robot, then continuing to operate the robot

is dangerous. Immediately stop using the robot and contact your distributor.

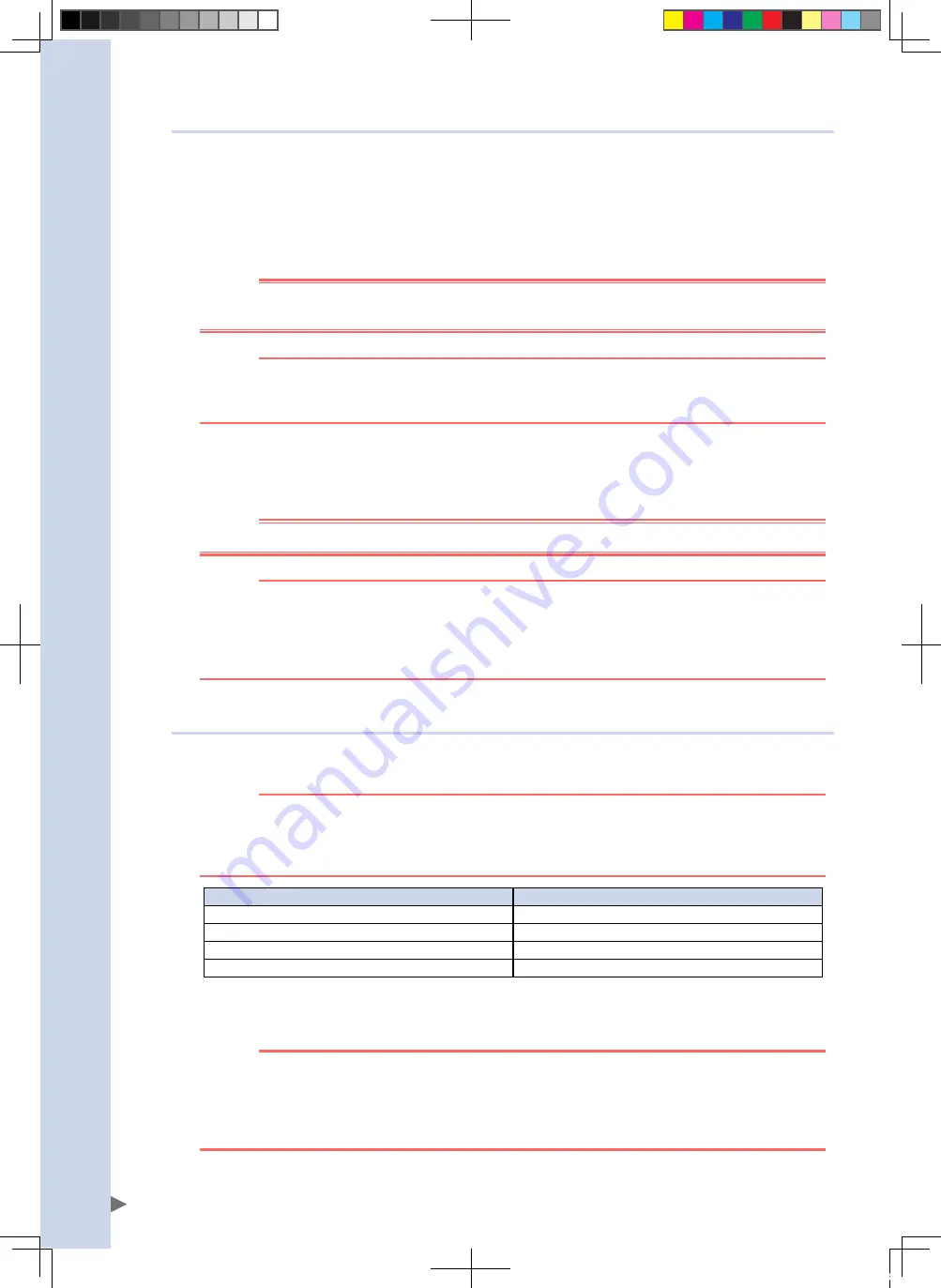

Damage or abnormal condition

Type of danger

Damage to machine harness or robot cable

Electrical shock, robot malfunction

Damage to robot exterior

Damaged parts fly off during robot operation

Abnormal robot operation (position deviation, vibration, etc.)

Robot malfunction

Z-axis (vertical axis) or brake malfunction

Z-axis unit falls off

2.

High temperature hazard

w

WARNING

• Do not touch the robot controller and robot during operation. The robot controller and robot body are very hot

during operation, so burns may occur if these sections are touched.

• The motor and speed reduction gear casing are very hot shortly after operation, so burns may occur if these

are touched. Before touching those parts for inspections or servicing, turn off the controller, wait for a while and

check that their temperature has cooled.

FLIP-X_maint_E_V1.50.indb 20

18/05/15 15:01

Summary of Contents for FLIP-X Series

Page 2: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 00...

Page 40: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 41: ...Chapter 1 Overview Contents 1 Overview 1 1 FLIP X_maint_E_V1 50 indb 1 18 05 15 15 01...

Page 42: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 44: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 46: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 60: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 72: ...FLIP X_maint_E_V1 50 indb 12 18 05 15 15 01...

Page 74: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 104: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...