2

Periodic inspection

2-5

2.3 Six-month inspection

Take the following precautions when performing 6-month inspection.

w

WARNING

WHEN THE BRAKE OF THE vERTICAL AxIS IS RELEASED, THE SLIDER AxIS MAY DROP, LEADING TO HAzARDOUS

SITUATION. WHEN APPLYING THE GREASE TO THE vERTICAL AxIS PARTS, DO NOT RELEASE THE BRAKE.

■

Inspection to be performed with the controller turned off

1

Turn off the controller.

2

Place a sign indicating the robot is being adjusted.

Place a sign showing that the robot is being inspected, to keep others from operating the controller

switch.

3

Perform the inspection.

Enter the safety enclosure and check the following points.

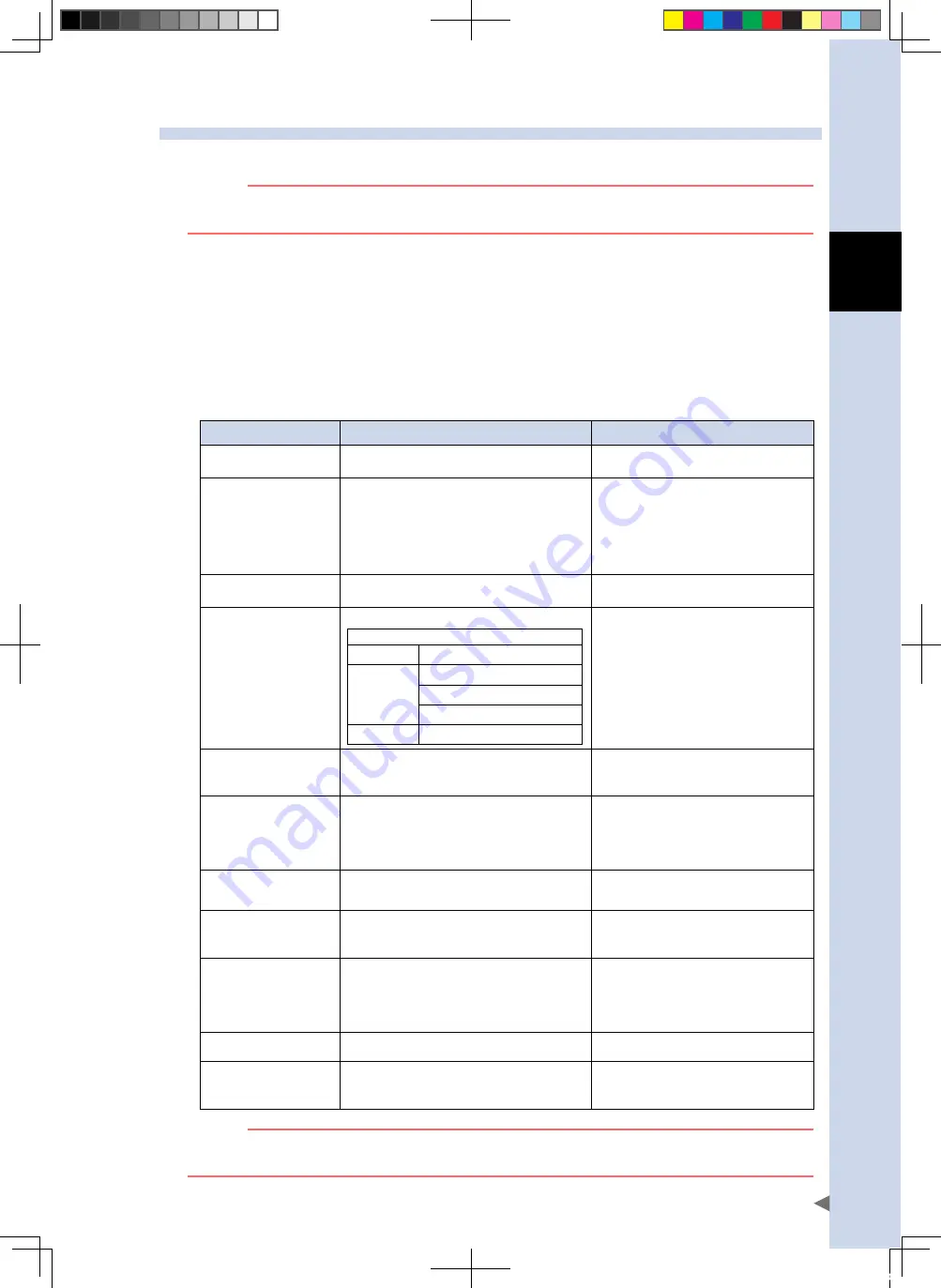

Checkpoint

Procedure

Remarks

Major bolts and screws on

exterior of robot main unit

Check for looseness and tighten if necessary. (*1)

Ball screw and linear

guide

• Check for looseness in the ball screw and linear

guide.

Tighten if necessary.

• Check for vibration during operation.

Tighten drive section, and X and Y axis

installation bolts if necessary.

• Check for wear and backlash. If any abnormality

is found, contact your distributor.

If problem is not solved or wear and

backlash are found, please contact your

distributor.

Controller

• Check for loose terminals.

• Check for loose connectors.

Application of grease to

ball screw/nut and linear

guide

Apply the grease every 6 months.

Recommended grease

N18

Daphne Eponex SR2 (Idemitsu)

Other than

N18

Alvania grease S2 (Showa Shell)

Alvania No.2 (Showa Shell)

Daphne Eponex No. 2 (Idemitsul)

Common

LG2 (NSK) For Clean Specification

See "3. Applying the grease" in this

Chapter.

Belt

• Check the timing belt for fault (scratch or

crack).

• Check the tension of the timing belt.

See Chapter 3, Adjustment.

Slider

Check for unusual wear or damage.

• If the friction is the cause of the trouble,

make the adjustment so that the

interference between the mating part and

slider is eliminated.

• If the slider is broken, contact your

distributor.

Resin slider

1. Check for backlash due to wear

2. Check for dirt or contamination.

1. Replace the resin slider.

(When replacing, contact your distributor.)

2. Perform the cleaning.

Bushing

• Check for unusual sound or vibration.

• Check for backlash due to wear

• Check that the clearance to the ball screw is wide.

When replacing,

see "7. Replacing the bushings" in Chapter 4

Wire

1. Check for scratch or fray.

2. Check for looseness.

1. Replace the wire.

(When replacing, contact your distributor.)

2. Adjust the wire tension.

(When replacing, contact your distributor.)

Resin pulley

Check for backlash due to wear

Replace the pulley.

(When replacing, contact your distributor.)

Insert

• Check that the positioning is correct during

operation.

• Check for unusual noise during operation.

See "3. Replacing the insert" in Chapter 4.

c

CAUTION

If the grease recommended by YAMAHA is not used, this may cause the service life of the ball screw or linear

guide to shorten.

FLIP-X_maint_E_V1.50.indb 5

18/05/15 15:01

Summary of Contents for FLIP-X Series

Page 2: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 00...

Page 40: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 41: ...Chapter 1 Overview Contents 1 Overview 1 1 FLIP X_maint_E_V1 50 indb 1 18 05 15 15 01...

Page 42: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 44: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 46: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 60: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 72: ...FLIP X_maint_E_V1 50 indb 12 18 05 15 15 01...

Page 74: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 104: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...