– 53 –

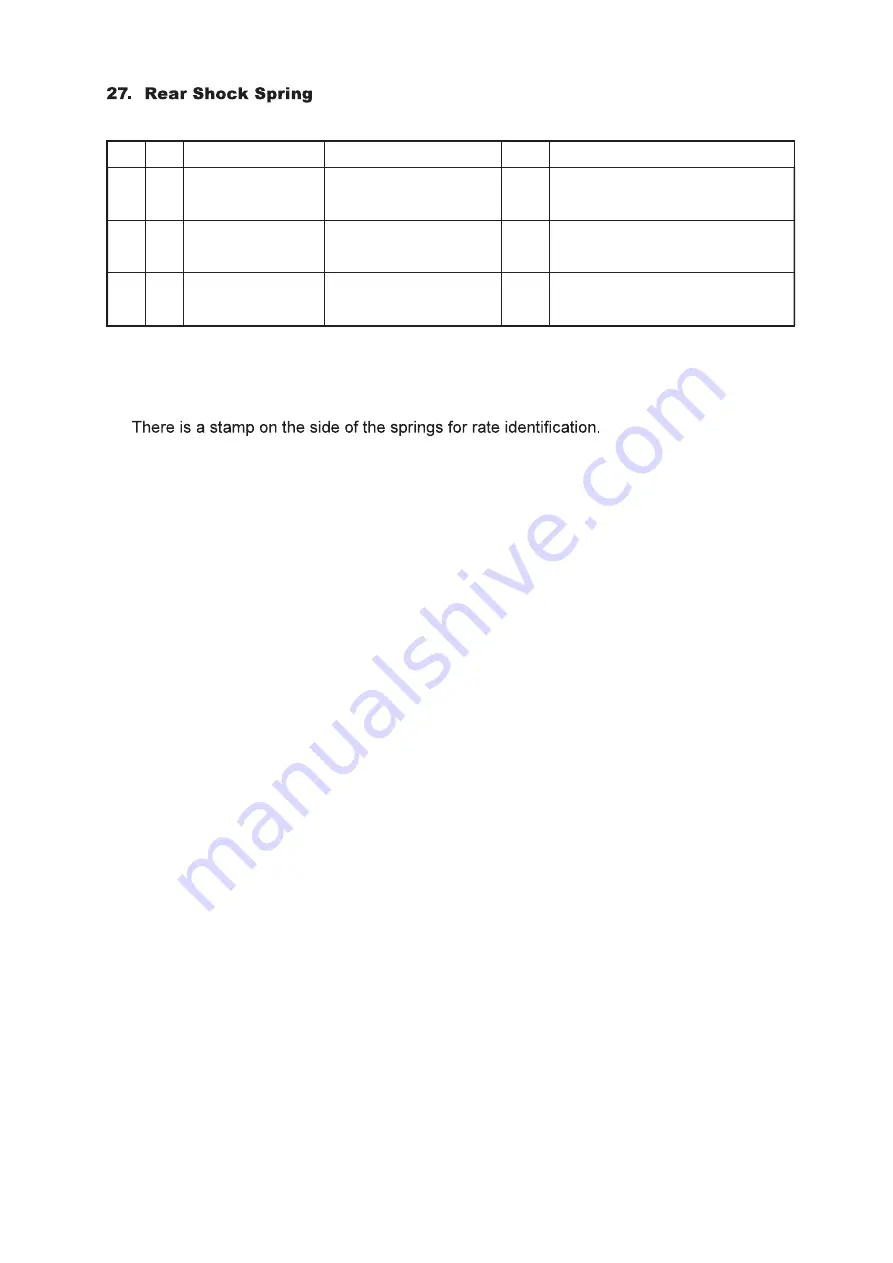

Parts List

•

These springs can be used with the standard absorbers.

•

•

The stamp number indicates the length, diameter and rate.

•

For spring replacement, see the BN6 STD. Service Manual.

•

The spring rate of the standard rear suspension is 103 N/mm.

•

The free length is 152.9 mm for STD / KIT springs.

R6180501Rev

No.

PART No.

PART NAME

Q'TY

REMARKS

1

BN6-22222-75

SPRG., Rr. SHOCK

1

108 N/mm

Identifying stamp:152.9-56-108

2

BN6-22222-80

SPRG., Rr. SHOCK

1

113 N/mm

Identifying stamp:152.9-56-113

3

BN6-22222-85

SPRG., Rr. SHOCK

1

118 N/mm

Identifying stamp:152.9-56-118

R6EN181106Rev

Summary of Contents for GYTR YZF-R6 2022

Page 1: ......

Page 11: ... 8 1 2 BN6 82590 70 WIRE HARNESS ASSY Details ...

Page 39: ... 36 ...

Page 44: ... 41 ...

Page 50: ... 47 ...

Page 51: ... 48 Transmission Assembly ...

Page 58: ... 55 References ...

Page 74: ...ENSOR NSOR Pb NSOR Pa SOR SOR SENSOR ENSOR TOR SENSOR ...

Page 75: ......

Page 76: ...Published by YAMAHA MOTOR ENGINEERING co LTD ...