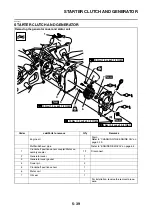

STARTER CLUTCH AND GENERATOR

5-42

2. Check:

• Starter clutch idle gear

• Starter clutch gear

Burrs/chips/roughness/wear

→

Replace the

defective part(s).

3. Check:

• Starter clutch gear contact surfaces

Damage/pitting/wear

→

Replace the starter

clutch gear.

4. Check:

• Starter clutch operation

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

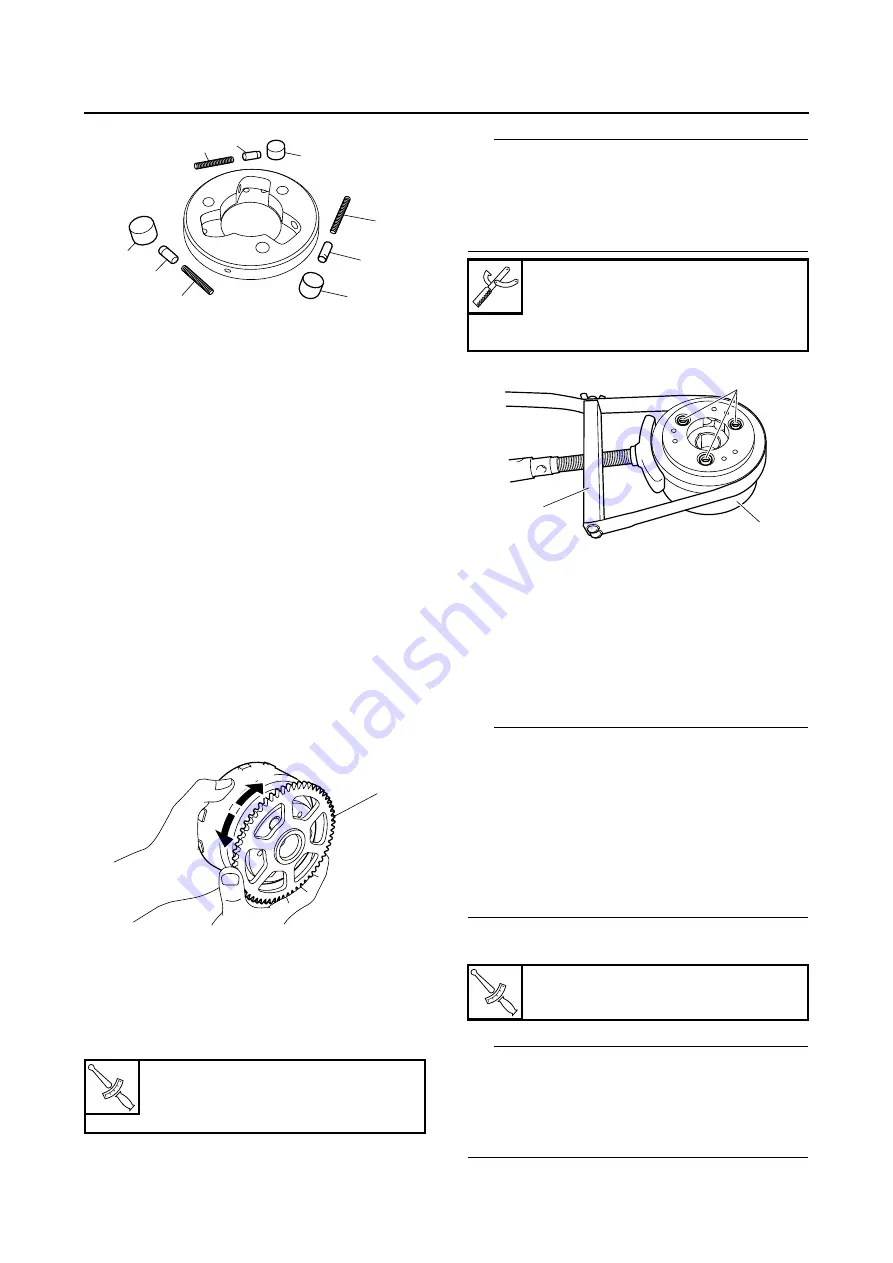

a. Install the starter clutch gear “1” onto the

starter clutch and hold the generator rotor.

b. When turning the starter clutch gear clock-

wise “A”, the starter clutch and the starter

clutch gear should turn freely, otherwise the

starter clutch is faulty and must be replaced.

c. When turning the starter clutch gear counter-

clockwise “B”, it should engage, otherwise

the starter clutch is faulty and must be re-

placed.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

EAS2DM1066

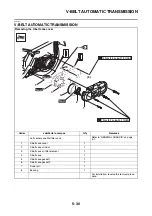

INSTALLING THE STARTER CLUTCH

1. Install:

• Starter clutch

• Starter clutch bolts “1”

TIP

• While holding the generator rotor “2” with the

sheave holder “3”, tighten the starter clutch

bolts.

• Do not allow the sheave holder to touch the

projection on the generator rotor.

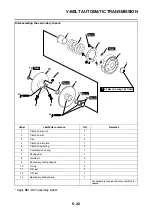

EAS2DM1067

INSTALLING THE GENERATOR

1. Install:

• Starter clutch gear

• Woodruff key

• Generator rotor

• Washer

• Generator rotor nut

TIP

• Clean the tapered portion of the crankshaft and

the generator rotor hub.

• When installing the generator rotor, make sure

the woodruff key is properly seated in the key-

way of the crankshaft.

• Lubricate the crankshaft end threads with en-

gine oil.

• Make sure that the blunt-edged corner of the

washer is facing outward.

2. Tighten:

• Generator rotor nut “1”

TIP

• While holding the generator rotor “2” with the

sheave holder “3”, tighten the generator rotor

nut.

• Do not allow the sheave holder to touch the

projection on the generator rotor.

T

R

.

.

Starter clutch bolt

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

LOCTITE®

1

1

3

2

3

2

3

2

1

1

A

B

Sheave holder

90890-01701

Primary clutch holder

YS-01880-A

T

R

.

.

Generator rotor nut

80 Nm (8.0 m·kgf, 58 ft·lbf)

1

3

2

Summary of Contents for MBK XMAX 2014

Page 1: ...2014 SERVICE MANUAL YP125R YP125RA 2DM F8197 E0 ...

Page 6: ......

Page 8: ......

Page 64: ...TIGHTENING TORQUES 2 17 Muffler tightening sequence 1 2 3 ...

Page 72: ...LUBRICATION SYSTEM DIAGRAMS 2 25 EAS2DM1116 LUBRICATION SYSTEM DIAGRAMS 1 2 3 4 5 3 ...

Page 78: ...CABLE ROUTING 2 31 Steering head front view 1 2 3 4 5 6 8 8 A 7 7 ...

Page 80: ...CABLE ROUTING 2 33 Front brake left side view for YP125R 1 2 2 1 1 2 2 D E A B C ...

Page 82: ...CABLE ROUTING 2 35 Front brake left side view for YP125RA 2 1 1 2 1 2 2 A B D E C ...

Page 92: ...CABLE ROUTING 2 45 Frame right side view 3 2 4 1 2 3 A B 6 5 3 A B 3 3 2 3 3 A A B A B B 3 ...

Page 94: ...CABLE ROUTING 2 47 Engine right side view 6 6 6 6 C D C D D C 10 B 9 5 6 1 2 8 3 4 5 6 7 A ...

Page 98: ...CABLE ROUTING 2 51 Frame left side view C D C D 2 1 E 1 2 D C 6 1 4 5 3 2 1 7 3 2 1 A B ...

Page 100: ...CABLE ROUTING 2 53 Engine left side view 1 1 1 1 1 2 3 4 5 6 7 8 9 7 7 A B A B A B 1 ...

Page 106: ...CABLE ROUTING 2 59 Rear brake right side view 2 2 2 2 2 2 1 1 2 3 A B C 3 ...

Page 110: ...CABLE ROUTING 2 63 ...

Page 228: ...REAR SHOCK ABSORBER ASSEMBLIES AND SWINGARM 4 89 ...

Page 231: ......

Page 291: ...CRANKSHAFT 5 60 a 1 ...

Page 292: ...CRANKSHAFT 5 61 ...

Page 302: ...WATER PUMP 6 9 ...

Page 313: ......

Page 331: ...CHARGING SYSTEM 8 18 ...

Page 349: ...COOLING SYSTEM 8 36 ...

Page 391: ...FUEL PUMP SYSTEM 8 78 ...

Page 400: ...IMMOBILIZER SYSTEM 8 87 a Light on b Light off ...

Page 401: ...IMMOBILIZER SYSTEM 8 88 ...

Page 405: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 92 ...

Page 439: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 126 ...

Page 464: ...ELECTRICAL COMPONENTS 8 151 ...

Page 476: ......

Page 477: ......

Page 478: ......