ELECTRICAL COMPONENTS

8-134

EAS27990

CHECKING THE BULBS AND BULB

SOCKETS

TIP

Do not check any of the lights that use LEDs.

Check each bulb and bulb socket for damage or

wear, proper connections, and also for continuity

between the terminals.

Damage/wear

→

Repair or replace the bulb,

bulb socket or both.

Improperly connected

→

Properly connect.

No continuity

→

Repair or replace the bulb, bulb

socket or both.

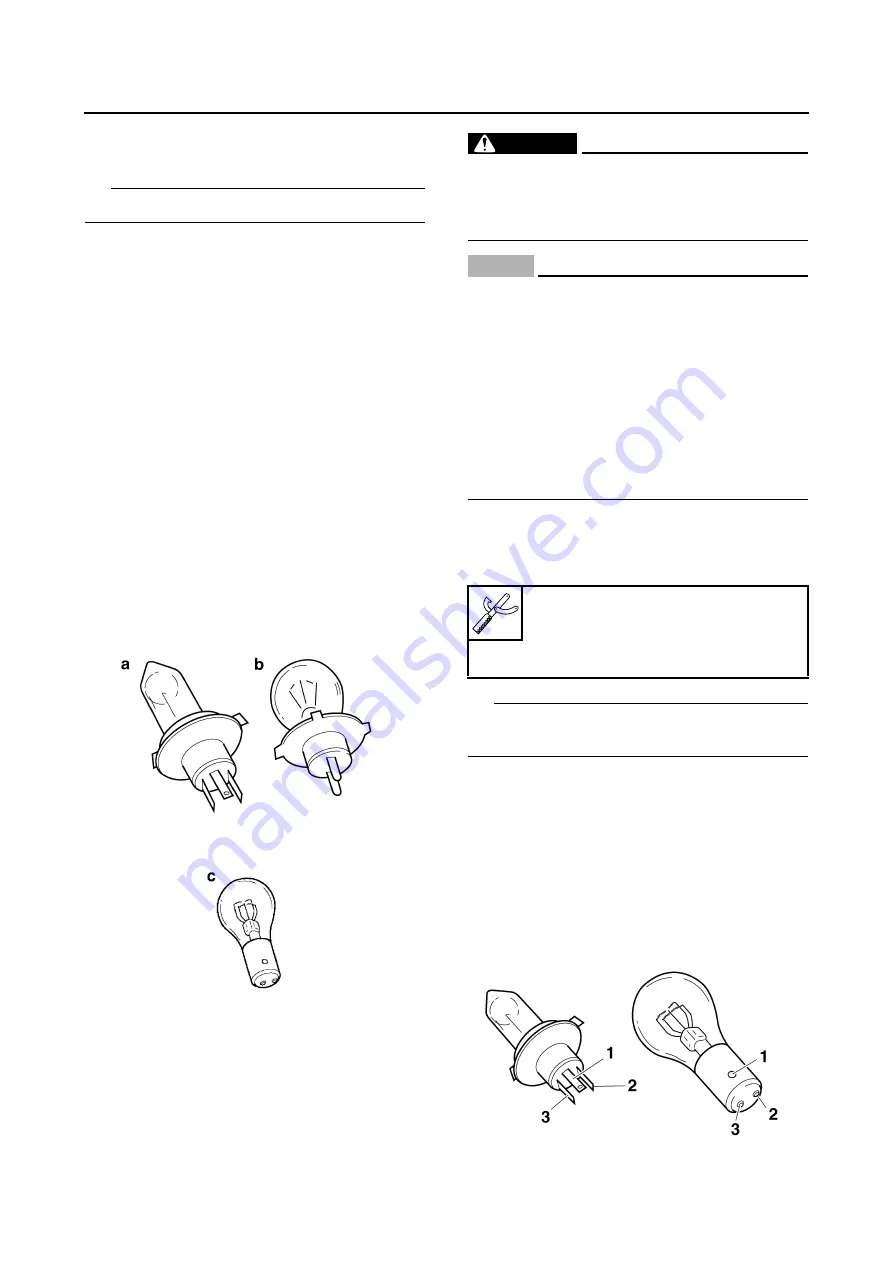

Types of bulbs

The bulbs used on this vehicle are shown in the

illustration.

• Bulbs “a” and “b” are used for the headlights

and usually use a bulb holder that must be de-

tached before removing the bulb. The majority

of these types of bulbs can be removed from

their respective socket by turning them coun-

terclockwise.

• Bulbs “c” are used for turn signal and tail/brake

lights and can be removed from the socket by

pushing and turning the bulb counterclockwise.

Checking the condition of the bulbs

The following procedure applies to all of the

bulbs.

1. Remove:

• Bulb

WARNING

EWA37P1018

Since headlight bulbs get extremely hot,

keep flammable products and your hands

away from them until they have cooled

down.

NOTICE

ECA37P1039

• Be sure to hold the socket firmly when re-

moving the bulb. Never pull the lead, other-

wise it may be pulled out of the terminal in

the coupler.

• Avoid touching the glass part of a headlight

bulb to keep it free from oil, otherwise the

transparency of the glass, the life of the

bulb, and the luminous flux will be adverse-

ly affected. If the headlight bulb gets soiled,

thoroughly clean it with a cloth moistened

with alcohol or lacquer thinner.

2. Check:

• Bulb (for continuity)

(with the pocket tester)

No continuity

→

Replace.

TIP

Before checking for continuity, set the pocket

tester to “0” and to the “

Ω

×

1” range.

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

a. Connect the positive tester probe to terminal

“1” and the negative tester probe to terminal

“2”, and check the continuity.

b. Connect the positive tester probe to terminal

“1” and the negative tester probe to terminal

“3”, and check the continuity.

c. If either of the readings indicate no continuity,

replace the bulb.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Summary of Contents for MBK XMAX 2014

Page 1: ...2014 SERVICE MANUAL YP125R YP125RA 2DM F8197 E0 ...

Page 6: ......

Page 8: ......

Page 64: ...TIGHTENING TORQUES 2 17 Muffler tightening sequence 1 2 3 ...

Page 72: ...LUBRICATION SYSTEM DIAGRAMS 2 25 EAS2DM1116 LUBRICATION SYSTEM DIAGRAMS 1 2 3 4 5 3 ...

Page 78: ...CABLE ROUTING 2 31 Steering head front view 1 2 3 4 5 6 8 8 A 7 7 ...

Page 80: ...CABLE ROUTING 2 33 Front brake left side view for YP125R 1 2 2 1 1 2 2 D E A B C ...

Page 82: ...CABLE ROUTING 2 35 Front brake left side view for YP125RA 2 1 1 2 1 2 2 A B D E C ...

Page 92: ...CABLE ROUTING 2 45 Frame right side view 3 2 4 1 2 3 A B 6 5 3 A B 3 3 2 3 3 A A B A B B 3 ...

Page 94: ...CABLE ROUTING 2 47 Engine right side view 6 6 6 6 C D C D D C 10 B 9 5 6 1 2 8 3 4 5 6 7 A ...

Page 98: ...CABLE ROUTING 2 51 Frame left side view C D C D 2 1 E 1 2 D C 6 1 4 5 3 2 1 7 3 2 1 A B ...

Page 100: ...CABLE ROUTING 2 53 Engine left side view 1 1 1 1 1 2 3 4 5 6 7 8 9 7 7 A B A B A B 1 ...

Page 106: ...CABLE ROUTING 2 59 Rear brake right side view 2 2 2 2 2 2 1 1 2 3 A B C 3 ...

Page 110: ...CABLE ROUTING 2 63 ...

Page 228: ...REAR SHOCK ABSORBER ASSEMBLIES AND SWINGARM 4 89 ...

Page 231: ......

Page 291: ...CRANKSHAFT 5 60 a 1 ...

Page 292: ...CRANKSHAFT 5 61 ...

Page 302: ...WATER PUMP 6 9 ...

Page 313: ......

Page 331: ...CHARGING SYSTEM 8 18 ...

Page 349: ...COOLING SYSTEM 8 36 ...

Page 391: ...FUEL PUMP SYSTEM 8 78 ...

Page 400: ...IMMOBILIZER SYSTEM 8 87 a Light on b Light off ...

Page 401: ...IMMOBILIZER SYSTEM 8 88 ...

Page 405: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 92 ...

Page 439: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 126 ...

Page 464: ...ELECTRICAL COMPONENTS 8 151 ...

Page 476: ......

Page 477: ......

Page 478: ......