POWR

TR

4-23

BRAKE

CAUTION:

Disc brake components rarely require disassem-

bly. DO NOT:

•

Do not disassemble components unless abso-

lutely necessary.

•

Do not use solvents on internal brake compo-

nents.

•

Do not use contaminated brake fluid for clean-

ing.

Use only clean brake fluid.

•

Do not allow brake fluid to contact the eyes,

otherwise eye injury may occur.

•

Do not allow brake fluid to contact painted

surfaces or plastic parts otherwise damage

may occur.

•

Do not disconnect any hydraulic connection,

otherwise the entire system must be disas-

sembled, drained, cleaned, and then properly

filled and bled after reassembly.

BRAKE PAD REPLACEMENT

NOTE:

It is not necessary to disassemble the brake cali-

per and brake hose in order to replace the brake

pads.

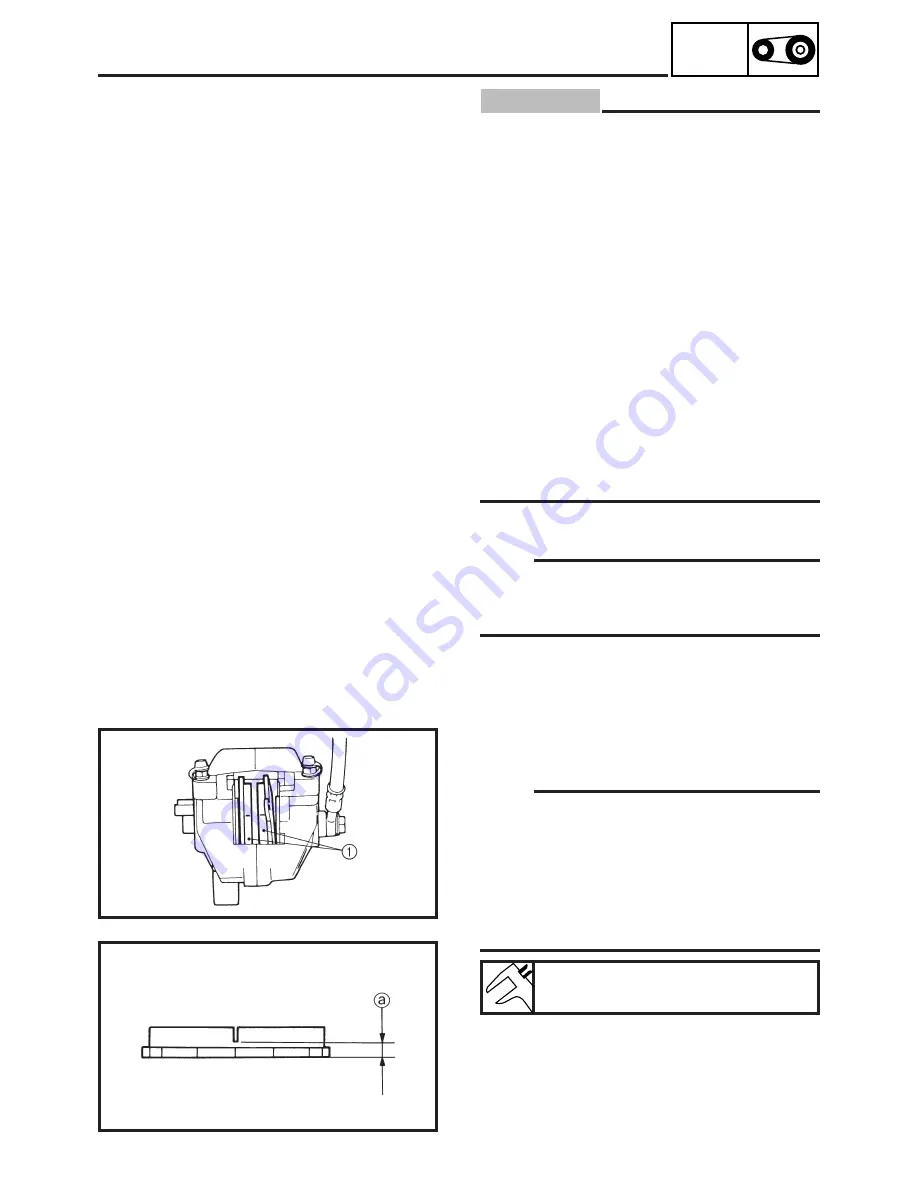

1. Remove:

•

Brake pads

1

NOTE:

•

Do not depress the brake lever when the caliper

or disc is off the machine otherwise the brake

pads will be forced shut.

•

Install a new brake pad spring and shims when

the brake pads are replaced.

•

Replace the pads as a set if either one is found

to be worn to the wear limit

a

.

Wear limit

a

:

4.2 mm (0.17 in)

SEJ4500

SEJ4510

Summary of Contents for MM600D

Page 1: ...MM600D MM700D SERVICE MANUAL LIT 12618 02 12 8EJ 28197 10 981033 ...

Page 47: ...2 34 INSP ADJ CARBURETOR TUNING Guide for carburetion SEJ2750 ...

Page 201: ...SPEC 9 23 CABLE ROUTING SEJ9160 ...

Page 203: ...SPEC 9 25 CABLE ROUTING SEJ9170 ...

Page 205: ...SPEC 9 27 CABLE ROUTING SEJ9180 ...

Page 207: ...SPEC 9 29 CABLE ROUTING SEJ9190 ...

Page 209: ...SPEC 9 31 CABLE ROUTING SEJ9200 ...