5-6

Chapter

5

USER WIRING AND USER PIPIN

1-3 Cable carrier specifications

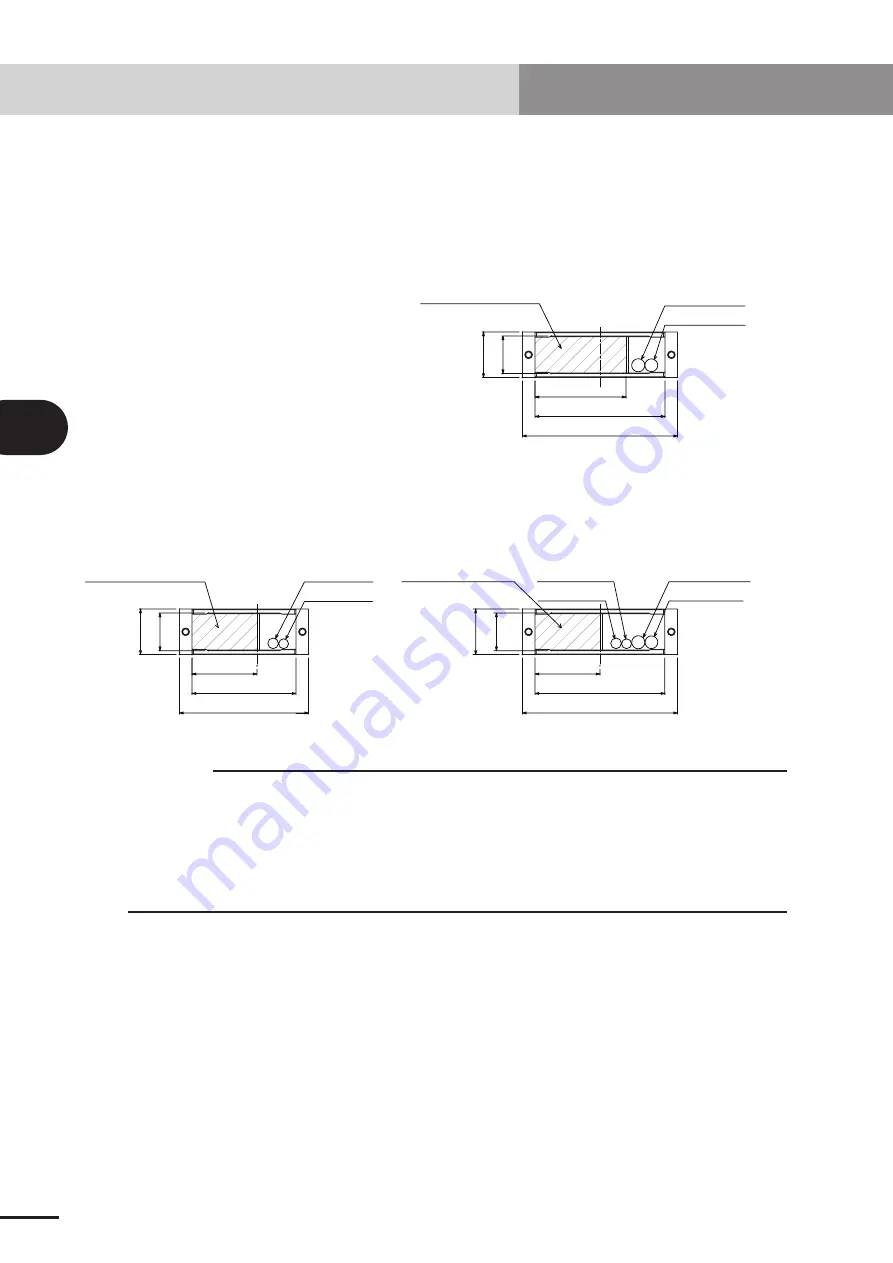

The cross-sectional shape of the cable carrier, and the shape of the cable mounted

initially by YAMAHA are shown below.

3-axis specifications X-Y cable carrier

Y-Z cable carrier

2-axis specifications X-Y cable carrier

29

35

29

35

50

80

100

Power wire

F

7.6

Signal wire

F

8.2

50

100

120

Signal wire

F

10.1

Power wire

F

7.6

Signal wire

F

8.2

Power wire

F

9.8

User wiring area

User wiring area

29

35

120

100

70

Power wire

F

9.8

Signal wire

F

10.1

User wiring area

c

CAUTION

• Harness and air tube must be laid in the unoccupied area. Do not set the user

wiring/piping in the YAMAHA robot cable domain.

• When setting the harness and air tube into the cable carrier, make sure that the

total cross-sectional area of all wires and pipes, including the YAMAHA cable,

inside the cable carrier does not exceed 30% of the cable carrier’s cross-

sectional

area.

1. Cable carrier type

Summary of Contents for NXY

Page 2: ......

Page 6: ......

Page 22: ......

Page 26: ...2 4 MEMO ...

Page 28: ......

Page 32: ...3 4 MEMO ...

Page 34: ......

Page 38: ...4 4 MEMO ...

Page 40: ......

Page 48: ......