2-2

Chapter

2

INST

ALLA

TION

3. Tightening torque

The accurate tightening torque will differ according to the seating face frictional

coefficient and the female screw material, etc. The recommended tightening torque is

between 9.8N·m to 12.7N·m (100kgf·cm to 130kgf·cm).

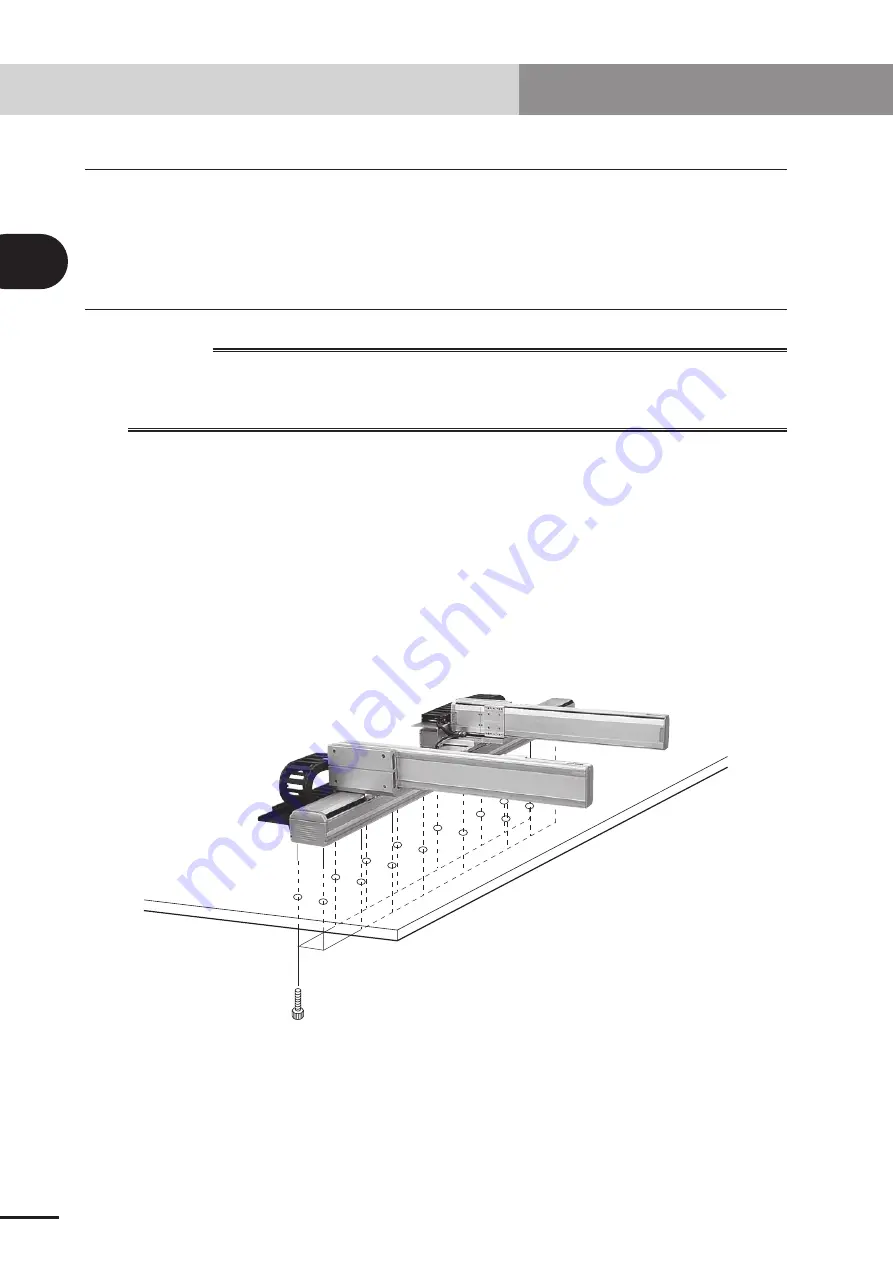

4. Installation methods

w

WARNING

ALWAYS USE THE DESIGNATED BOLT, AND SECURELY TIGHTEN IT WITH THE CORRECT

TORQUE. FAILURE TO OBSERVE THIS COULD CAUSE THE ROBOT POSITION TO DEVIATE,

AND COULD ALSO LEAD TO SERIOUS ACCIDENTS.

■

Method A

1) Open a

φ

6.5 through hole on the installation base's robot installation surface. For

machining positions, refer to the external view and dimensions in the catalog or

website (www.yamaha-motor.co.jp/global/industrial/robot).

2) Set the robot on the installation base and fix with M6 bolts from below.

3. Tightening torque

Summary of Contents for NXY

Page 2: ......

Page 6: ......

Page 22: ......

Page 26: ...2 4 MEMO ...

Page 28: ......

Page 32: ...3 4 MEMO ...

Page 34: ......

Page 38: ...4 4 MEMO ...

Page 40: ......

Page 48: ......