6-23

6-22

6

Specifications

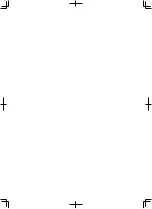

Robot connector (I/O signal connector)

2.

Robot connector (I/O signal connector)

Cable carrier

on robot

Hood

To robot cable

(I/O signal wires)

D.G

6

5

4

3

2

1

Z-

Z+

S+

C+

C-

7

9

F.G

+5 V

S-

0.15mm

2

twisted pair

Shield

8

6

5

4

3

2

1

7

9

8

Signal

Connection

Remarks

Pin No.

Pin No.*

Blue

Orange

Green

Brown

Gray

Red

Black

Yellow

*Internally connected

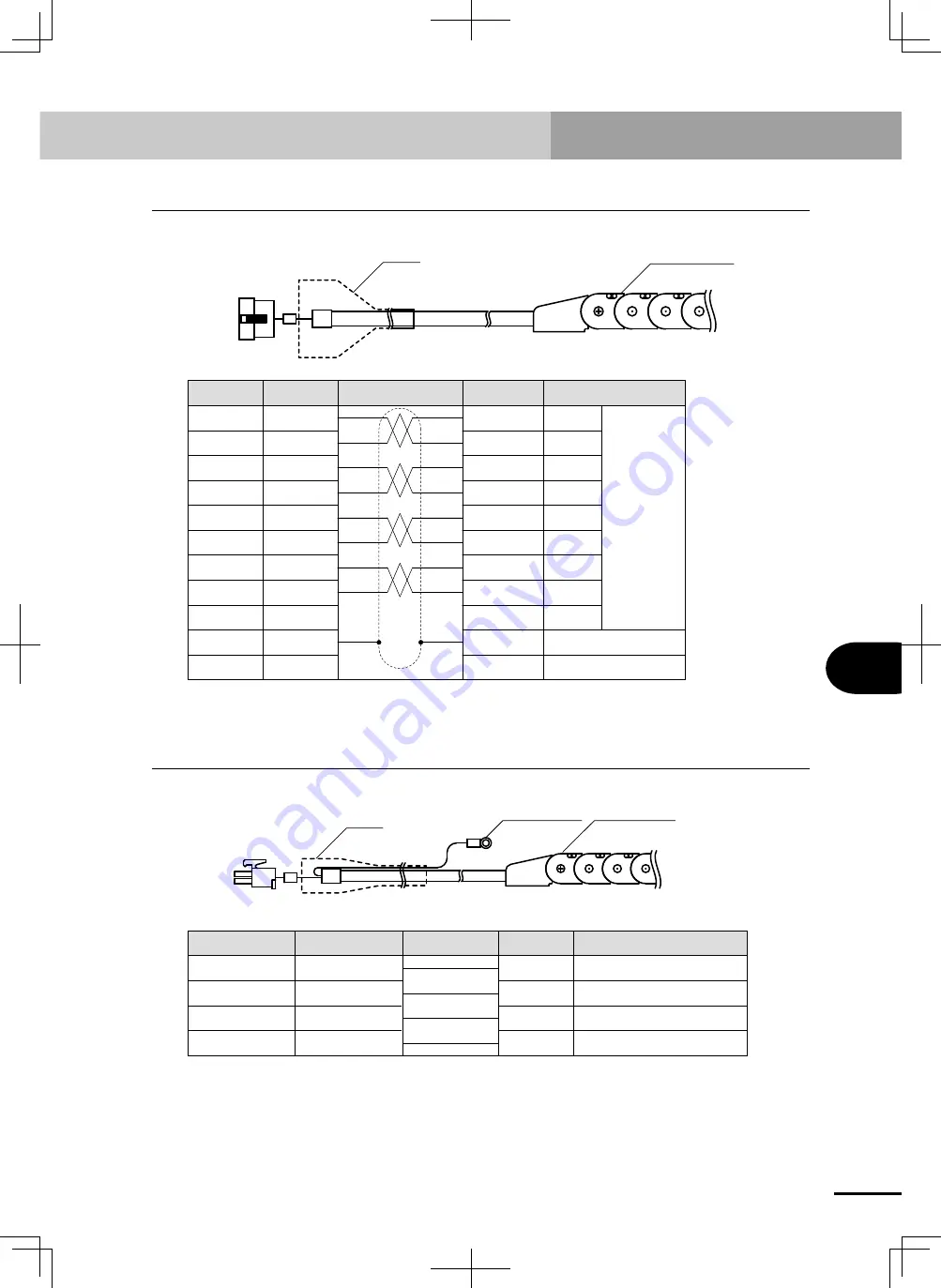

3.

Robot connector (motor connector)

Ground wire

Cable carrier

on robot

Hood

To robot cable

(motor wires)

3

2

1

4

3

2

1

0.5 mm

2

, 0.75mm

2

Green

0.5 mm

2

, 0.75 mm

2

Red

0.5 mm

2

, 0.75 mm

2

White

0.5 mm

2

, 0.75 mm

2

Black

Signal

Pin No.

Pin No.*

Connection

Remarks

Round terminal

Motor wire FG

U

W

V

*Internally connected