14

Suspension forks are available with many different damping systems, each of which requires its

own form of maintenance.

Basic suspension fork maintenance is to ensure that the upper parts of the inner fork legs are clean

and free of sand, gravel or other debris. Chrome-plated inner legs must be maintained with a

chrome care product.

Please note that a suspension fork requires special care, and in order to function satisfactorily, it

must be serviced at least once a year or more frequently depending on the manufacturer’s instruc-

tions. Remember to check the service intervals.

A simple fork, which only contains a steel spring, does not require much maintenance, while more

sophisticated forks are sensitive to the condensation that forms in all forks and should therefore be

disassembled, lubricated and have the oil changed after 50 - 100 hours of use.

As it requires a great deal of insight and professional skill to carry out the necessary service, it is

recommended to have the bicycle dealer carry it out.

Useful links:

www.rockshox.com

www.foxracingshox.com

www.srsuntour-cycling.com

www.rst.com.tw

Tires

Always keep the tires inflated to the correct tire pressure. It makes driving easier and prevents

damage to tires, tubes and rims.

The correct tire pressure is indicated on the side of the tyre, e.g. as INFLATED TO 40 -65 psi or

max. 60 psi. If you don’t have a pump with a tire pressure gauge, the pressure can be checked by

pressing your thumbs hard against the tire. The tire should feel hard.

It is recommended to check the tires before riding for correct pressure and to remove stones that

have become stuck. This avoids many punctures.

Tubes

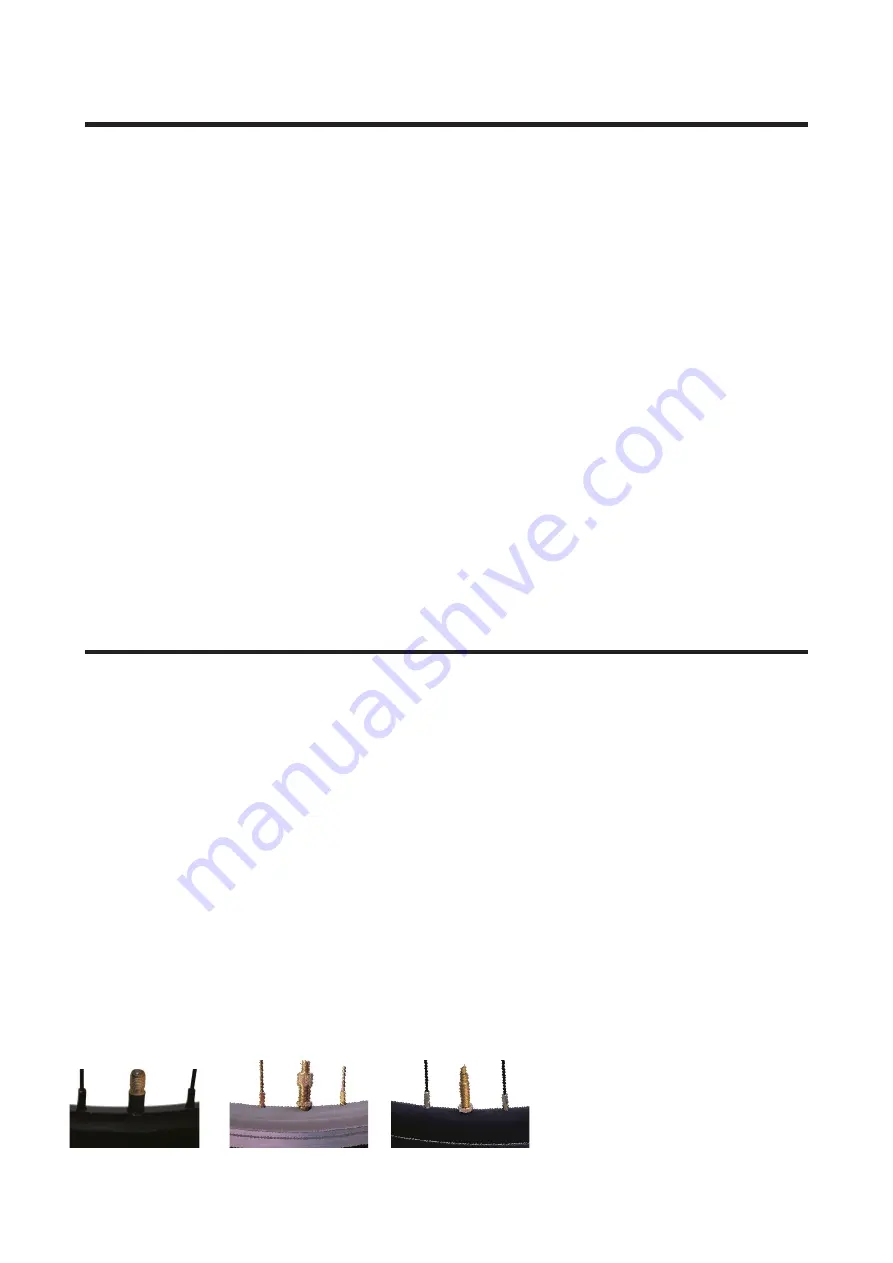

Bicycle tubes can be fitted with different valves. Atom, Presta and Schrader valves.

Please note that when pumping tubes with a Presta valve, the small nut on the valve must be

loosened before pumping. If this does not happen, air will not enter the tube, and you risk breaking

the valve with the pump.

Suspension forks

Tires and tubes

Schrader valve

Regular Atom valve

Presta valve

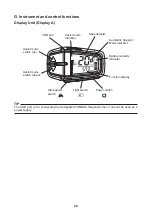

Summary of Contents for PW SYSTEM

Page 18: ...18 Multi Location Battery 600 External Crossover Battery 400 500 ...

Page 53: ...53 ...

Page 59: ...59 Cap Charging connector ...