FEATURES

1-11

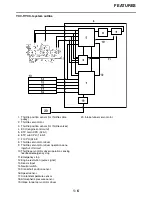

To adjust the brightness of the multifunction

meter displays and tachometer

1. Turn the key to “OFF”.

2. Push and hold the “SELECT” button.

3. Turn the key to “ON”, and then release the

“SELECT” button after five seconds.

4. Push the “RESET” button to select the

desired brightness level.

5. Push the “SELECT” button to confirm the

selected brightness level. The control

mode changes to the shift timing indicator

light activity function.

To set the shift timing indicator light activity

function

1. Push the “RESET” button to select one of

the following indicator light activity settings:

• The indicator light will stay on when acti-

vated. (This setting is selected when the

indicator light stays on.)

• The indicator light will flash when acti-

vated. (This setting is selected when the

indicator light flashes four times per sec-

ond.)

• The indicator light is deactivated; in other

words, it will not come on or flash. (This

setting is selected when the indicator light

flashes once every two seconds.)

2. Push the “SELECT” button to confirm the

selected indicator light activity. The control

mode changes to the shift timing indicator

light activation function.

To set the shift timing indicator light activation

function

NOTE:

The shift timing indicator light activation func-

tion can be set between 10000 r/min and

18000 r/min. From 10000 r/min to 13000 r/min,

the indicator light can be set in increments of

500 r/min. From 13000 r/min to 18000 r/min,

the indicator light can be set in increments of

200 r/min.

1. Push the “RESET” button to select the

desired engine speed for activating the

indicator light.

2. Push the “SELECT” button to confirm the

selected engine speed. The control mode

changes to the shift timing indicator light

deactivation function.

To set the shift timing indicator light deactiva-

tion function

NOTE:

• The shift timing indicator light deactivation

function can be set between 10000 r/min and

18000 r/min. From 10000 r/min to 13000

r/min, the indicator light can be set in incre-

ments of 500 r/min. From 13000 r/min to

18000 r/min, the indicator light can be set in

increments of 200 r/min.

• Be sure to set the deactivation function to a

higher engine speed than for the activation

function, otherwise the shift timing indicator

light will remain deactivated.

1. Push the “RESET” button to select the

desired engine speed for deactivating the

indicator light.

2. Push the “SELECT” button to confirm the

selected engine speed. The control mode

changes to the shift timing indicator light

brightness function.

To adjust the shift timing indicator light bright-

ness

1. Push the “RESET” button to select the

desired indicator light brightness level.

2. Push the “SELECT” button to confirm the

selected indicator light brightness level.

The right display will return to the odometer

or tripmeter mode.