– 42 –

ENG

ENGINE

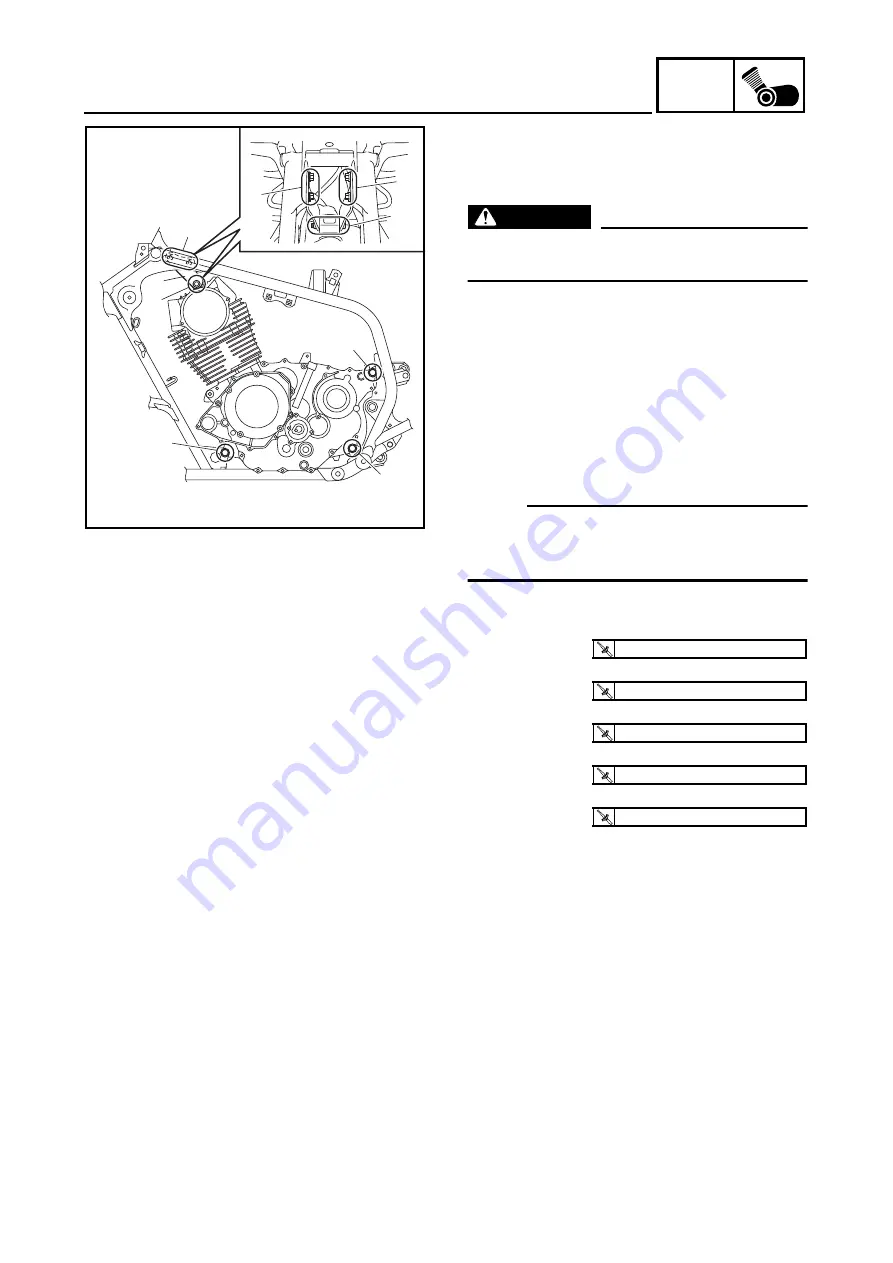

ENGINE REMOVAL

INSTALLING THE ENGINE

WARNING

Securely support the machine so there is

no danger of it falling over.

1. Install:

• engine assembly

2. Install:

• engine lower mounting bolt (rear)/nut

1

• engine upper mounting bolt (rear)/nut

2

• engine lower mounting bolt (front)/nut

3

• engine bracket (left and right)

4

• engine bracket bolts

5

• engine upper mounting bolt (front)/nut

6

NOTE:

• All mounting bolts should be installed from

the right of the machine.

• Do not fully tighten the bolts and nuts.

3. Tighten:

• engine lower mounting bolt (rear)/nut

1

• engine upper mounting bolt (rear)/nut

2

• engine lower mounting bolt (front)/nut

3

• engine bracket bolts

5

• engine upper mounting bolt (front)/nut

6

5

6

5

1

3

2

4

6

5

T

R

.

.

73 Nm (7.3 m · kg, 53 ft · lb)

T

R

.

.

73 Nm (7.3 m · kg, 53 ft · lb)

T

R

.

.

73 Nm (7.3 m · kg, 53 ft · lb)

T

R

.

.

33 Nm (3.3 m · kg, 24 ft · lb)

T

R

.

.

33 Nm (3.3 m · kg, 24 ft · lb)

ENGINE REMOVAL

Summary of Contents for Raptor YFM350S

Page 1: ...YFM350S3GD AE7 SUPPLEMENTARY SERVICE MANUAL ...

Page 2: ......

Page 66: ......

Page 67: ......

Page 68: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...