For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

104/273

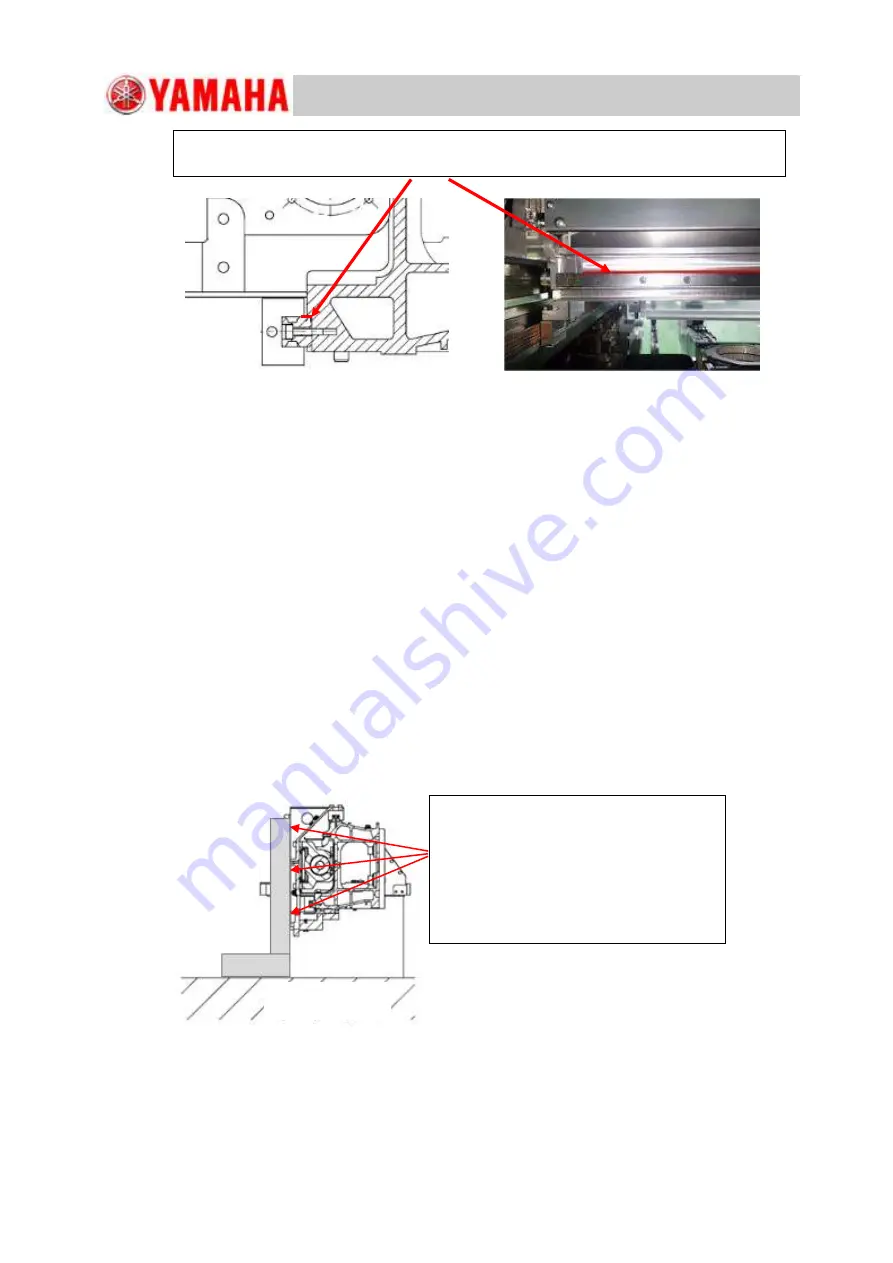

Fig.C38

(3)

Attach the beam setup jig in the X-axis beam and set it up on the surface plate.

(4)

Attach the head plate assembly onto the guide temporarily.

* Fix it temporarily, because the adjustment operation is required.

(5)

Measure the squareness of the head plate assembly (Refer to the following description

for the measurement procedure).

①

Put the set-square against the head plate assembly surface as shown in the

following figure.

②

Measure the gap between the set-square and plate assembly using the shim.

* The measurement should be performed in the following three locations. Make

sure to record the results.

③

Make sure that the difference between the maximum value and minimum value in

the measurement results in these three locations, should be within 0.03mm.

* If not, repeat the temporary fixing steps.

④

Measure the values at the center of the beam and the both ends of the beam (three

locations) using the above procedure. Press it (against the section in red lines in the

following figure) and tighten the set bolts (M4L14).

Fig.C39

Measure the gap using the shim in the

section with red lines in the figure.

Compare the values measured in the

three locations and adjust so that the

difference between the maximum and

minimum values is within 0.03mm.

Surface Plate

The section with red line in the figure shows the beam reference surface.

Fix the linear guide with the linear guide pressed against the reference surface.