For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

117/273

3.8. Y-Axis Scale Head Adjustment Procedure

3.8.1. Preparation of Adjusting Jig

For USB-422 DS15P

(1) Prepare the personal computer (Software for

adjustment

"

ST700 Scale MonitorHTI Specially

Designed Version

"

has beeninstalled), adjusting

jig unit.

(2) Connect the personal computer (hereinafter

called

"

PC

"

) and adjusting jig unit as follows.

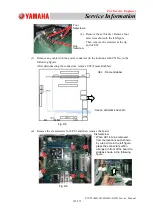

Connect the PC’s USB connector to the

adjusting jig D-SUB connector (in the frame in

Fig. C66-*1).

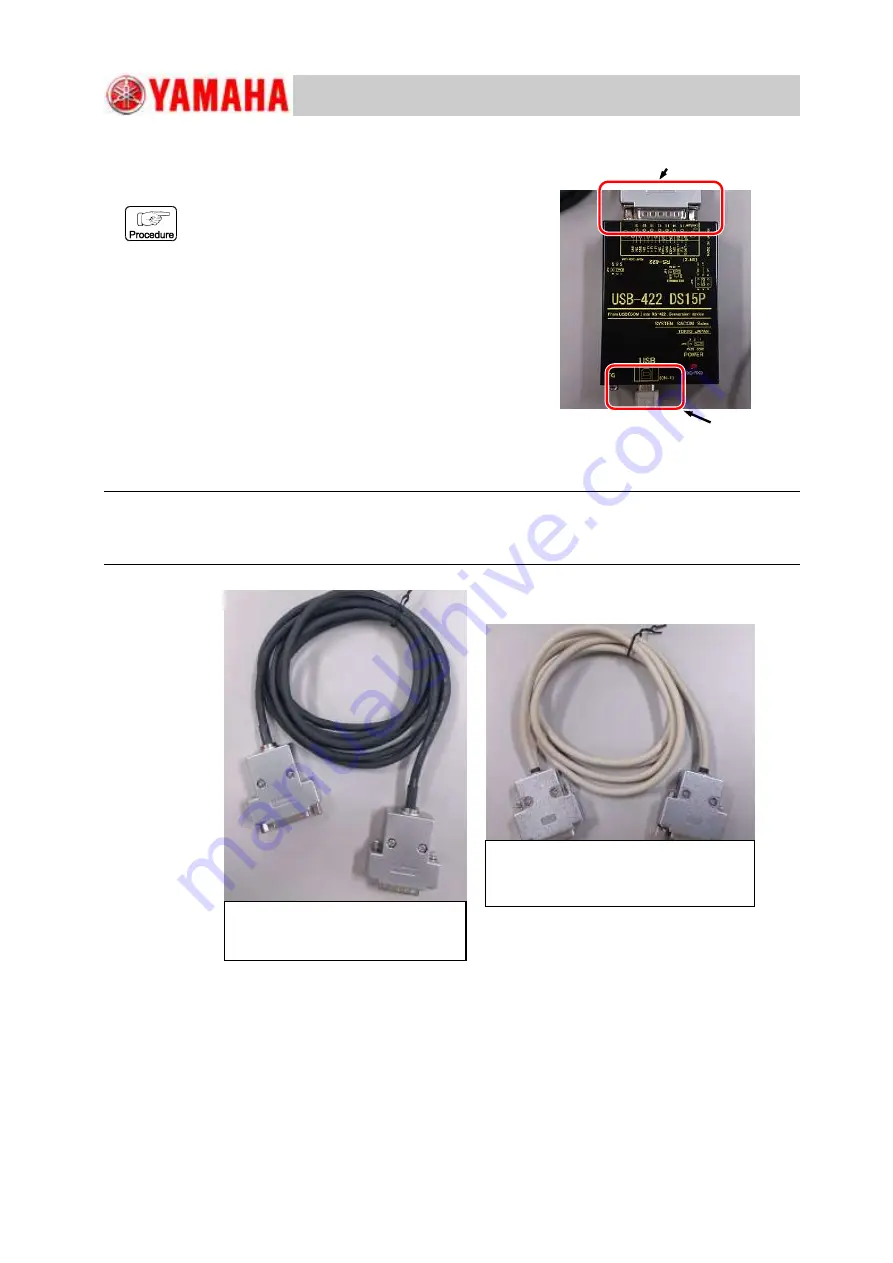

(3) There are two relay cables to connect to the

adjusting jig (Black and White cables).

Use the cable appropriate for the connector to be

connected (Refer to Fig. C67).

Note:

Take care so that no cables interfere with the machine because the beam is

operated in the adjustment operation. Also, because there are two types of cable, use them according

to the situation (Refer to Fig.C67).

Fig.C67

*2 Scale Head Side

*1 PC Side

Fig.C66

①

This cable is used to connect to

the scale head connector.

②

This cable is used to connect to the

connector on the relay panel.