For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

141/273

(9)

Remove the dial gauge and tighten the coupling setscrew with the specified torque.

After the adjustment, turn ON the servo for the NS-axis and XY-beam and perform

the "All Zero" operation.

Fastening Bolt

M2.5

×

L8, Screw Lock (1401B)

Fastening Torque

1 Nm (Newton)

(Tighten the bolt by hand at the field).

(10) Return to the "MOTOR" window of the "Maint." windows and set the dial gauge onto

the nozzle No. 1 position again and move the NS-axis at angles of "-25°","-20°", "0°"

"20°" and "25°" with the manual axis operation and confirm the cam delivery.

Standard Value Range:

/- 0.01 mm

In the case that it is out of the range, adjust it by loosening the coupling setscrew.

* After the check, remove the dial gauge from inside the machine.

* During the check operation, make sure not to move the XY beam absolutely. Only

NS-axis can be moved.

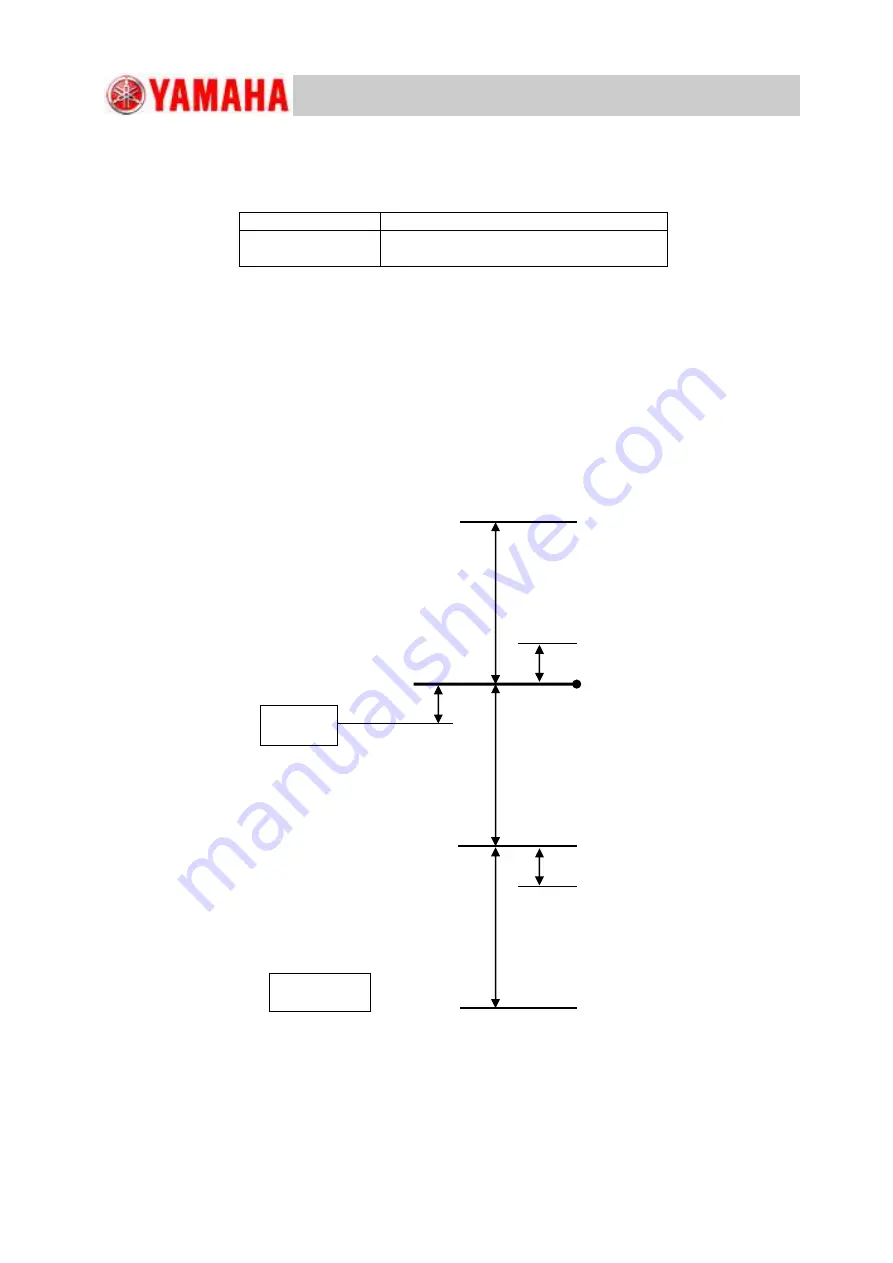

(11) Check that the upper/lower interlock positions on the NL-axis are as follows.

(12) After the adjustment, teach the [NL-Axis Origin Offset] and save the data.

Refer to "1.4.5.1 NL-Axis Origin Offset " in Chapter 1, for the teaching operation.

(-)

Mechanical Stopper

NL-Axis Zero

0.2 ± 0.2

NL-Axis Interlock

21.0mm

NL-Axis Full Stroke

(+) Mechanical Stopper

0.5mm

22.0±0.4mm

Unit : mm

B

0503

Fig.D44

-0.9+0.6

-0.9-0.35

(-)

Soft Limit

(+) Soft Limit

0

(

-

0.5)