For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

143/273

(4)

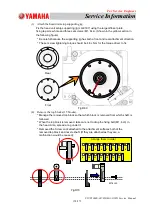

Loosen the motor set bolt on the fixed side with the nut, adjust the motor position so

that the timing belt tension becomes

30 to 35N

, and fix it.

* Tightening Torque : 86.2 to 96 cN

m

SPAN

40MM

WEIGHT

0.25gf/cm

2

WIDTH

6MM

Belt Tension

30 to 35N

(5) Start up the machine and perform the zeroing operation for "NL → HL → NS → DD"

axes in this order.

At that time, make sure that the height of the pulley on the center shaft is the same as

that of the pulley on the motor side. Select "Maint.", "DVC Check", "Motor", "Select

Changed Block", "NL" and "Selection Axis" in this order, and press the [START]

button in the "Selection Axis" window.

The same procedure is applied to the HL-, NS- and DD-axis to zero.

(6) Fix the pulleys at the position where the nozzle No. 1 cam follower center agrees with

the roller rest center (center deviation: +/- 0.2 mm) while the NS-axis and DD-axis are

at their home positions.

At that time, arrange the pulley fixing block so that the hexagon hole of the fastening

bolt (M2L8) is turned outside (easy positioning for fastening).

* Tightening Torque : 56 to 68 cN

m

Fig.D47